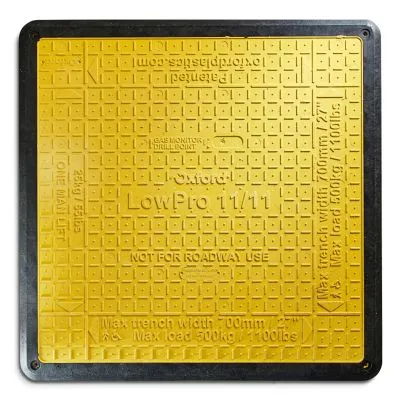

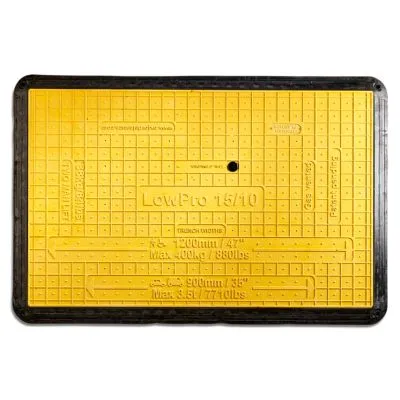

Composite Road Plate - 44 Tonnes - LowPro 15/05

Product Highlights

- 44-tonne capacity - Composite structure safely bridges wide trenches under HGV load.

- Lightweight modular design - Installed by 2 people without lifting equipment.

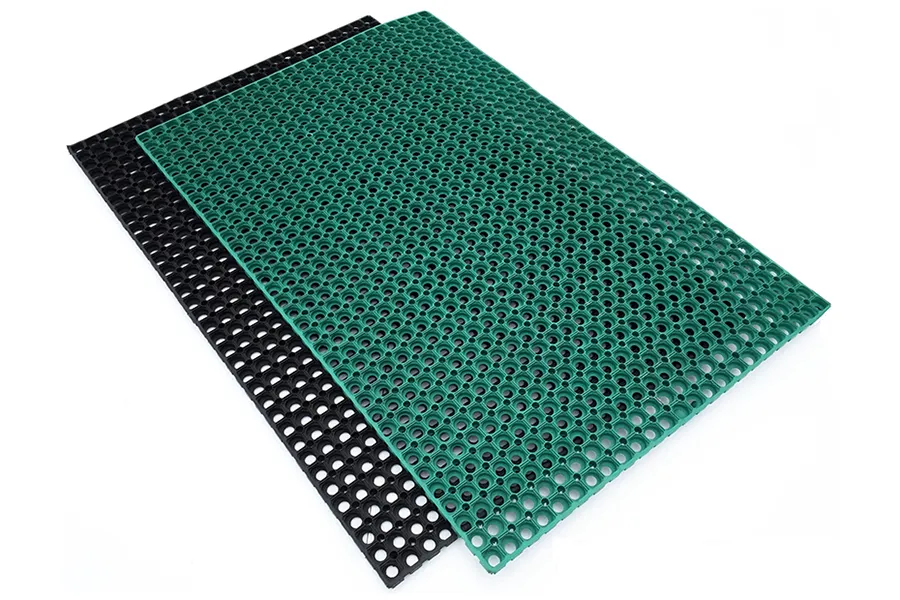

- Noise-reducing edges - Rubber grips and flexible edges minimise vibration and movement.

SKU TC2214

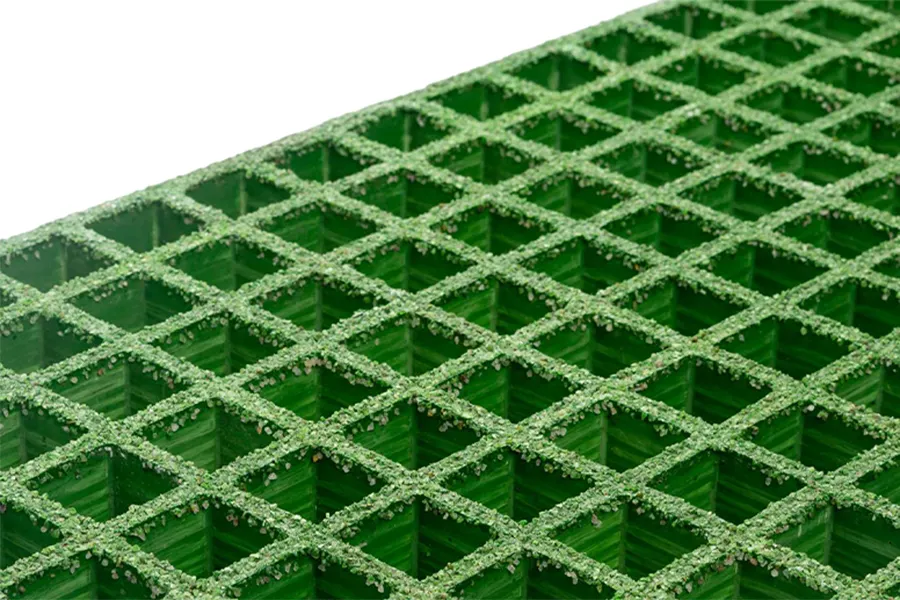

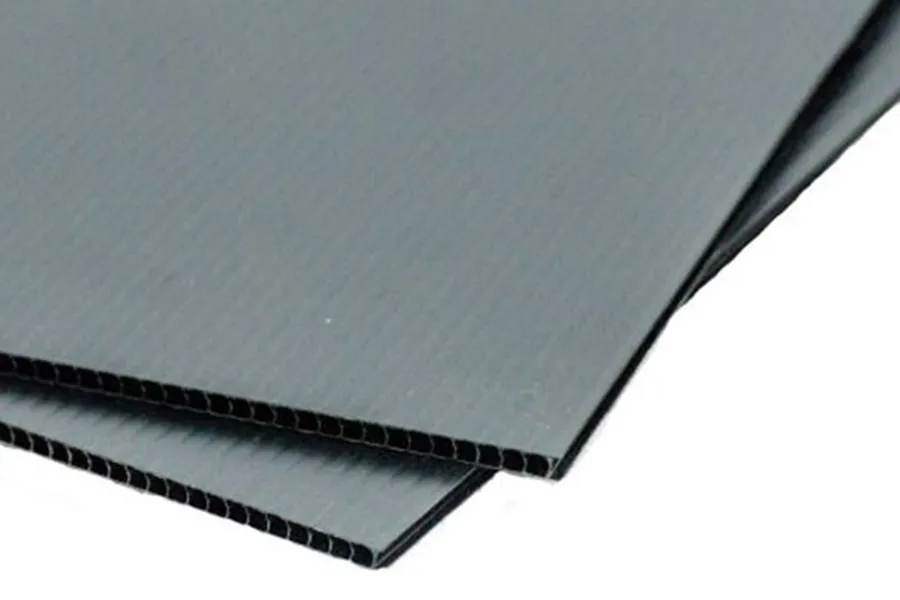

Designed for rapid, high-load access, the Composite Road Plate 44T offers a safe and efficient ramps road solution for crossing excavations. Built to carry up to 44 tonnes over a 700mm trench, this trench cover eliminates the need for heavy machinery, enabling fast installation by just two operatives. Made from composite plastic with rubber grips, this system is a versatile alternative to traditional road plates or trench boards.

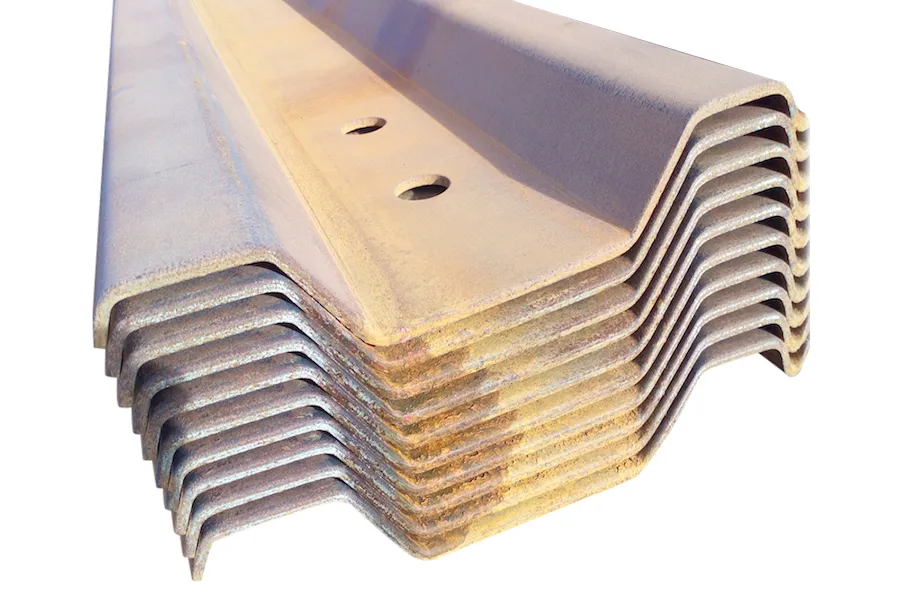

The modular trench plate system comprises lightweight inner sections and optional end pieces that connect securely using heavy-duty locking connectors. These prevent lateral movement and allow precise trench length coverage, avoiding gaps and improving on-site safety. Each unit is 1500mm x 500mm and only 40kg, allowing for quick deployment with minimum disruption on live roads and worksites.

- Install in minutes – 2-person lift trench boards designed for fast deployment with no lifting gear.

- Superior grip & stability – Rubberised base and flexible lateral pins lock into the trench to prevent shifting.

- Trench cover with traffic calming – Yellow composite top increases visibility and slows approaching vehicles.

- Modular ramps road system – Customisable lengths for trench protection over 700mm gaps.

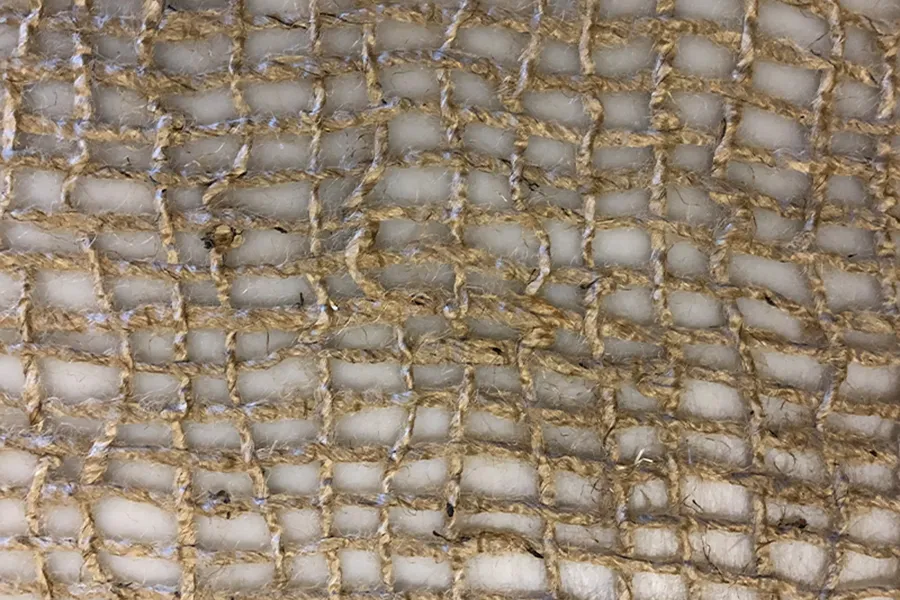

- Exceeds anti-slip standards – Textured surface improves traction in wet or oily conditions.

Unlike traditional ground plates or steel road plates, this composite trench cover system eliminates noise, risk, and environmental impact during installation. It's ideal for fibre optic contractors, highway maintenance teams and utility providers that need a reliable ramps road system that conforms to safety expectations. Whether deployed for hours or weeks, the product withstands high axle loads without movement, flex, or structural fatigue.

Important: Load ratings are based on normal operating temperatures and correct installation. In freezing conditions or extreme heat, maximum load capacity may vary.

HERMEQ stock a wide range of Ground Mats, Bog Mats, Trench Covers & Road Plates conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

- Weight – 40kg per inner section, 23kg for end plates.

- Colour – High-visibility yellow with contrasting black for added awareness.

- Dimensions – 1500mm x 500mm modules ensure flexible layout configurations.

- Surface – Textured composite plate offers enhanced anti-skid traction in harsh environments.

With integrated drop pins and rubber skirts, this ramps road system ensures lateral locking and noise absorption across rough terrain. Pre-drilled anchor points allow for secure semi-permanent installs, and with no need for cranes or forklifts, operational overhead is drastically reduced. The modularity of the design eliminates poor trench coverage, common with rigid ground plates or trench boards, and supports highly adaptable workspaces.

Each road plate is quick to install with a simple interlocking mechanism, streamlining safety compliance without slowing down workflows. Designed for contractors and councils who need reliability and high load performance in compact units, this trench cover solution delivers exceptional performance with reduced health and safety risk.

Road Plate (Inner Piece)

- Length (end to end) - 1500mm

- Width - 500mm

- Weight - 40Kg

- Colour - Yellow & black as standard

End Plate (End Piece)

- Length (end to end) - 1500mm

- Width - 500mm

- Weight - 23Kg

- Colour - Yellow

How much weight can the composite ramps road support?

It supports up to 44 tonnes, making it ideal for HGV and plant vehicle access over trenches.

Do I need lifting equipment to install it?

No. Each section weighs 40kg and can be safely installed by two people without mechanical lifting aids.

Is this trench cover suitable for public roads?

Yes. It meets all road plate safety standards including anti-slip and visibility requirements for highway use.

How many sections do I need?

It depends on the trench length. Each module is 1.5m long and you can add or remove sections as needed for full trench coverage.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH