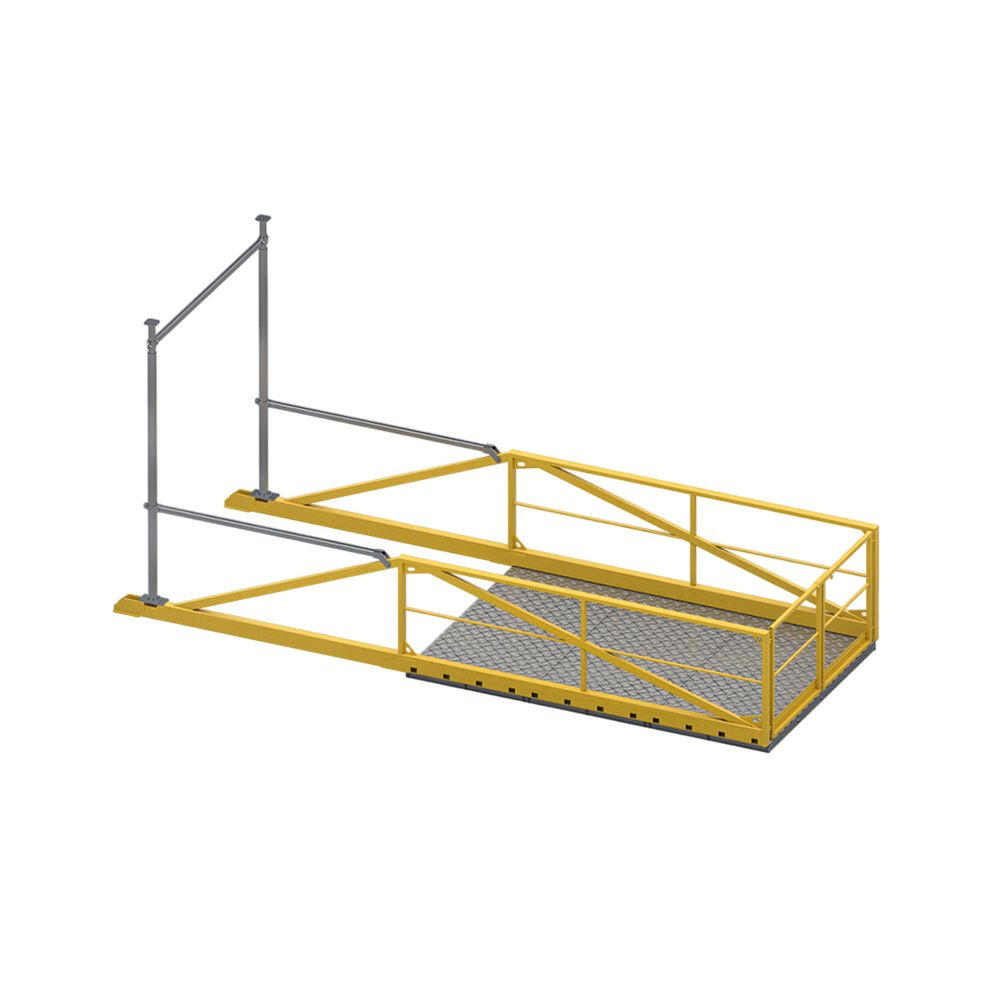

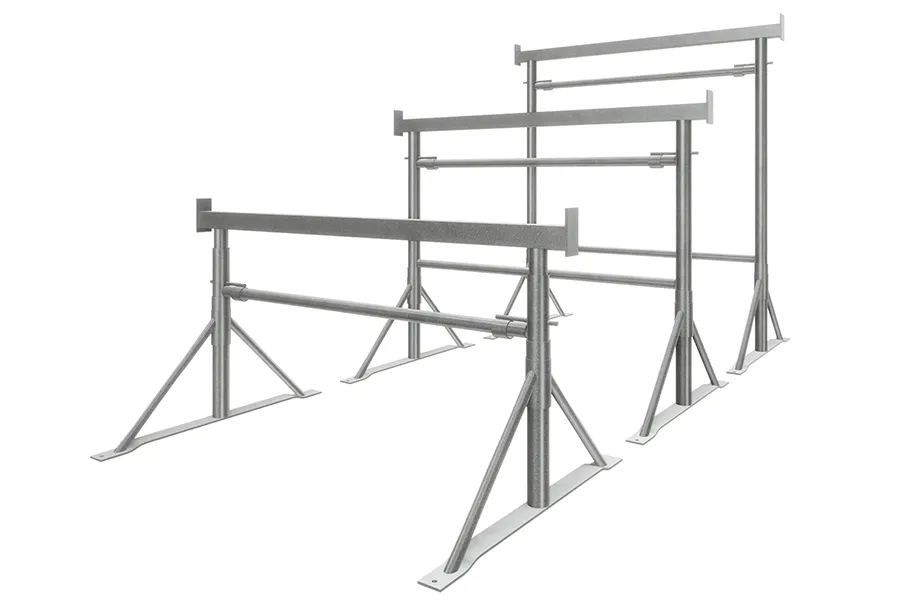

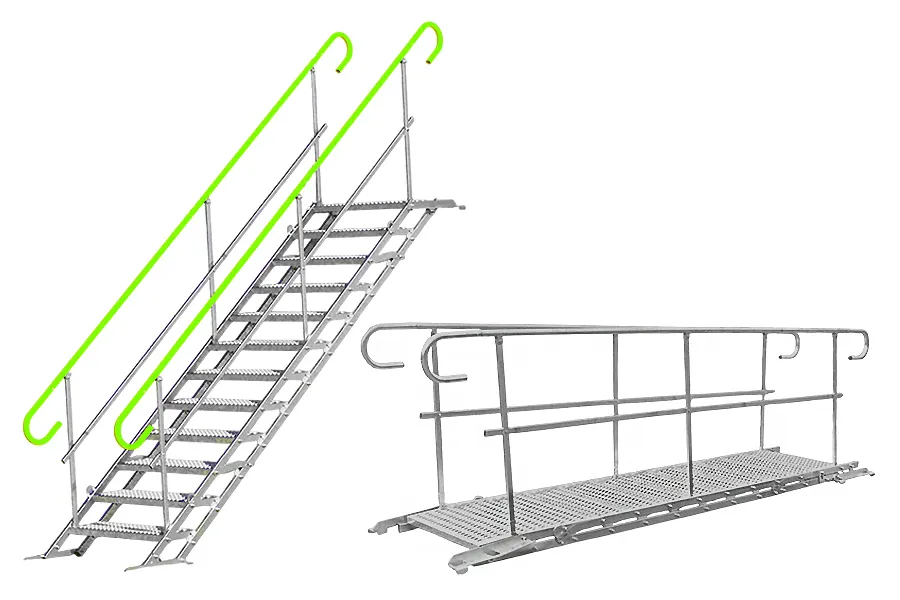

Temporary Unloading Platform

SKU WO99991z

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

Key Features & Benefits

- High load-bearing capacity: Withstands up to 4000kg (40 kN), providing reliable support for heavy materials and tools during crane-assisted unloading on active sites.

- Certified safety compliance: Approved by IMBiGS and meets EN 12811-3 standards, ensuring best-in-class performance for height-based operations.

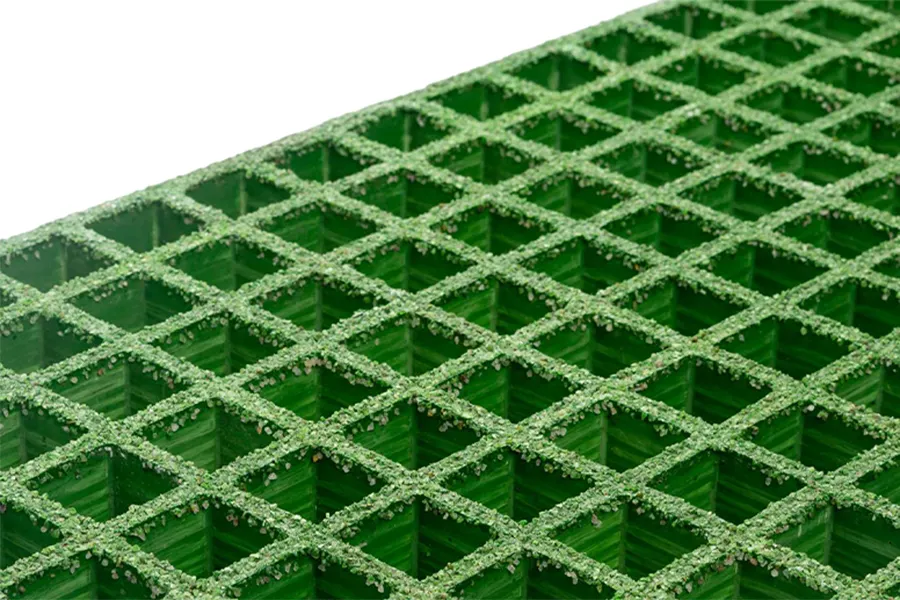

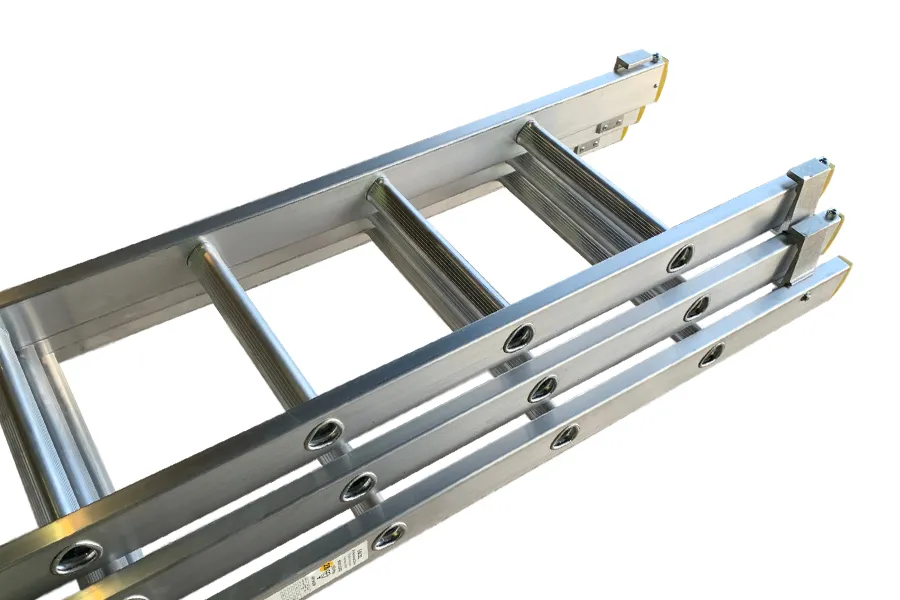

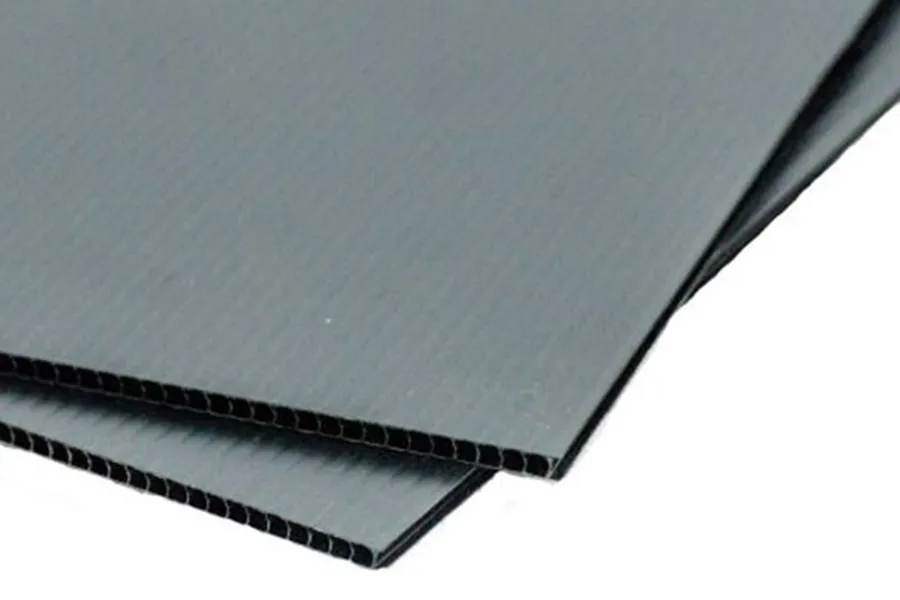

- Anti-slip surface and harness holders: Grooved aluminium flooring enhances worker safety, while integrated harness points offer added fall protection.

- Flexible installation options: Can be securely anchored to the floor slab or supported with braces, adapting to various structural layouts.

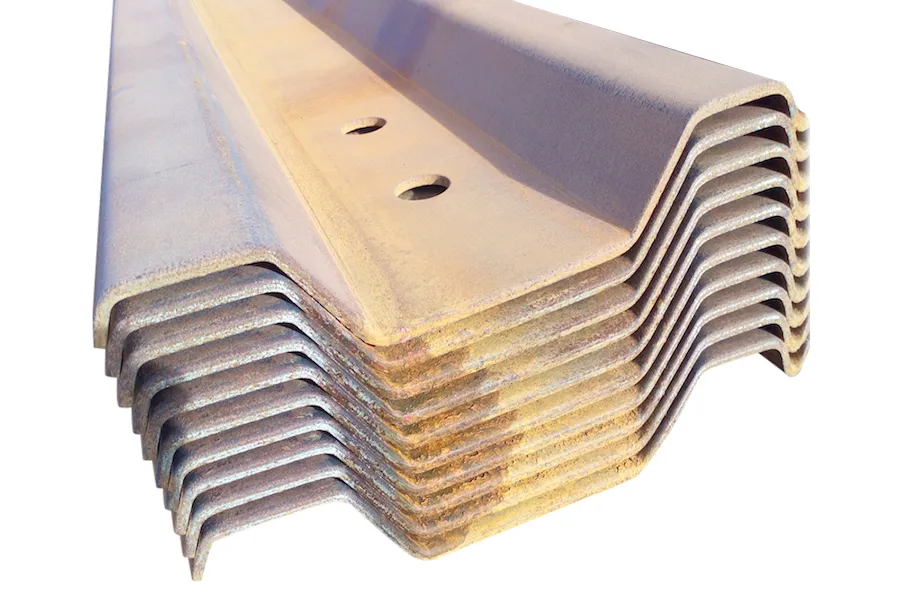

- Corrosion resistance and easy assembly: Hot-dip galvanised or powder-coated finish protects against weathering; bolted structure simplifies transport and installation.

The temporary unloading platform is a professional-grade solution designed to streamline material handling on construction sites. Engineered for safe and efficient crane-lifting operations, it enables the rapid transport of heavy goods and tools from ground level to elevated working areas. With a certified 4000 kg weight capacity, it accommodates substantial loads without compromising stability or site safety. Safety remains paramount in working-at-height scenarios. That’s why this platform is fully compliant with EN 12811-3 and has received positive certification from the IMBiGS Institute. Its grooved aluminium lining delivers robust anti-skid protection, while dedicated safety harness holders give personnel added security during use.

Installation is both intuitive and versatile, with two mounting options either anchored directly into the concrete floor slab or supported using braces. This dual-method flexibility ensures suitability across various project requirements and structural designs. The bolted construction allows for swift assembly and disassembly, saving both time and labour costs during setup or relocation.

To ensure long-term durability, the platform benefits from corrosion protection via hot-dip galvanisation to PN-EN ISO 1461 or powder coating, making it resistant to the harsh environmental conditions commonly faced on-site.

| Length | 1.25 Meters | 1.5 Meters | 2.2 Meters |

| Weight (kg) |

751 - without supports 814 - with supports |

810 - without supports 863 - with supports |

960 - without supports 1013 - with supports |

| Platform Width (A) - mm | 1456 | 1706 | 2403 |

| Unloading Area Width (B) - mm | 1250 | 1500 | 2200 |

| Materials | S235 / S355 Steel, Aluminium | ||

| Intended Use | The platform functions as a finished solution ensuring proper unloading area for materials transported using cranes and other lifting equipment. | ||

Uses & Applications

Designed to address core challenges faced in vertical logistics, the temporary unloading platform offers a practical high-performance solution for multi-level construction environments. Its certified 4000kg capacity ensures you can safely lift and unload bulk materials such as bricks, cladding, tools, and pallets right where work is taking place. By minimising manual handling and optimising crane use, the platform directly contributes to improved site productivity and reduced accident risk.

Key features include a grooved aluminium surface that provides excellent grip, even under wet conditions. This anti-slip layer helps prevent workplace injuries during loading and unloading activities. Additionally, integrated safety harness holders enhance fall protection, supporting compliance with site safety regulations.

The platform's positive certification by the IMBiGS Institute, confirming full conformity with the EN 12811-3 standard, demonstrates a clear commitment to safe design. This European standard ensures the platform is structurally sound, stable, and suitable for use in elevated environments, offering procurement teams peace of mind.

Real-world use cases span across building and construction sectors, particularly during the erection of high-rise structures or multi-storey projects. It serves as a critical link in crane-based lifting operations, providing a temporary yet secure location for material handoffs between tiers. Two versatile installation methods—anchoring to the floor slab or using braces—allow it to adapt to specific project conditions, including uneven terrain or varying building geometries. The bolted structure simplifies assembly and disassembly, while galvanised or powder-coated finishes shield against corrosion and prolong operational life.

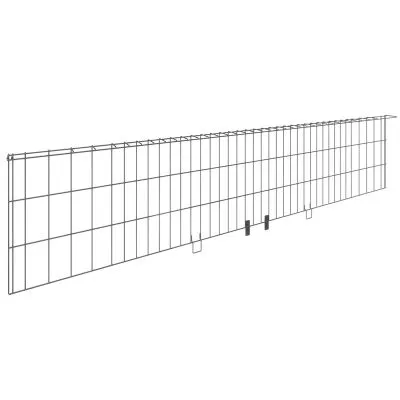

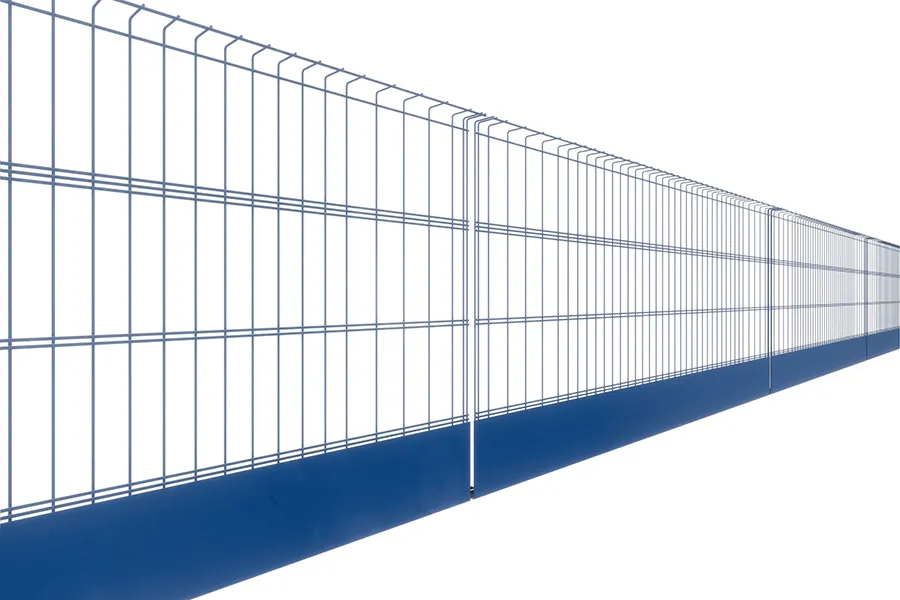

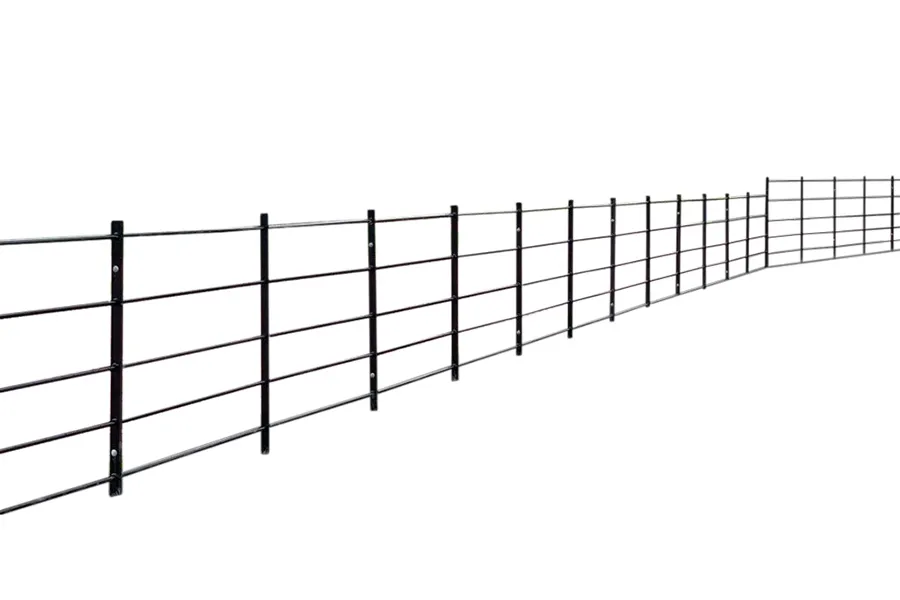

The platform also functions as a temporary storage zone, keeping materials off the ground and out of the way, reducing on-site clutter. This can streamline workflows and reduce trip hazards on active job sites. If your operation involves regular crane lifts and multi-storey builds, the temporary unloading platform is a critical addition to your logistics setup. It also pairs effectively with systems like Edge Protection Barriers to ensure complete site safety and efficiency.

Complementary Products

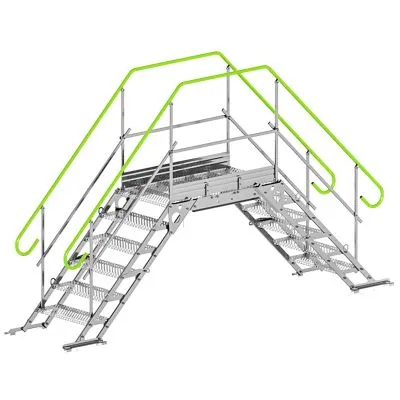

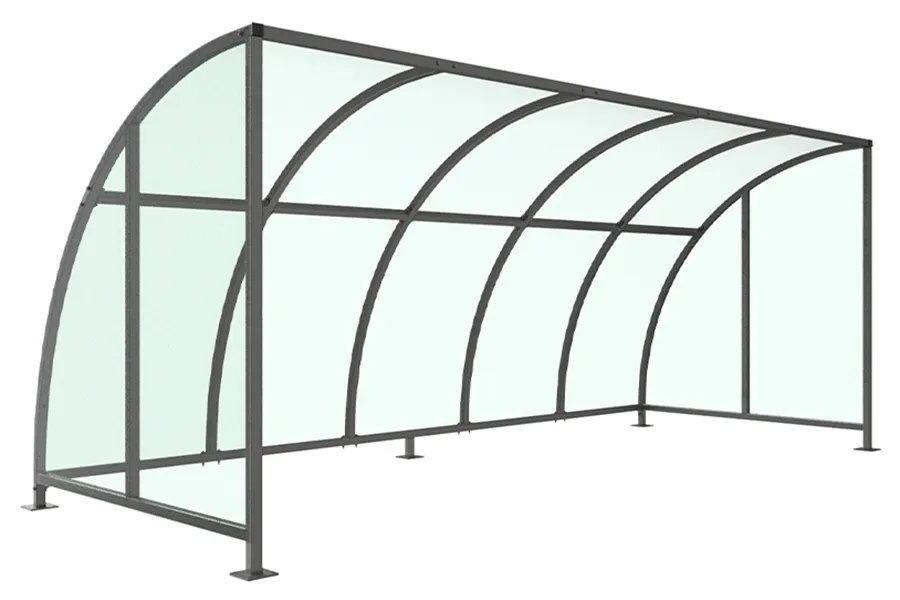

If your project involves restricted spatial layouts or requires access around circular structures such as silos, tanks or lift shafts, the Temporary Spiral Staircase offers a suitable option. Its spiral design enables safe navigation in tighter spaces while maintaining compliance with safety regulations.

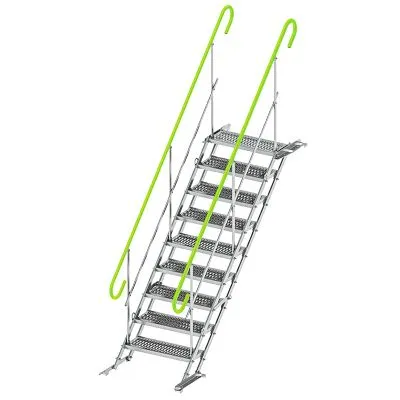

The linear configuration of the Temporary Stairway is perfect for straight multi-level access. It is ideal for internal shaft access during fit-outs, tight scaffolding environments, or heritage refurbishments where preserving structural aesthetics is critical. This makes it especially useful for projects requiring a blend of accessibility and design sensitivity.

For job sites that shift daily or require constant reconfiguration of access points, using both stair types in tandem ensures flexibility and ongoing compliance. The spiral staircase’s modularity also allows it to scale with project demands, much like the straight stair system. Both stairways are engineered for ease of handling, on-site assembly, and long-term reliability under heavy site use. Choosing between them depends on spatial constraints and preferred access layout.

HERMEQ stocks a wide range of equipment for Working at Height including Edge Protection Systems, Fall Arrest Systems, and Harnesses & Lanyards conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

| Length | 1.25 Meters | 1.5 Meters | 2.2 Meters |

| Weight (kg) |

751 - without supports 814 - with supports |

810 - without supports 863 - with supports |

960 - without supports 1013 - with supports |

| Platform Width (A) - mm | 1456 | 1706 | 2403 |

| Unloading Area Width (B) - mm | 1250 | 1500 | 2200 |

| Materials | S235 / S355 Steel, Aluminium | ||

| Intended Use | The platform functions as a finished solution ensuring proper unloading area for materials transported using cranes and other lifting equipment. | ||

What is the permissible load of the unloading platform?

The platform is rated for a maximum load of 40 kN, equivalent to 4000 kg, regardless of how the weight is distributed across the surface.

Does the platform form a seamless surface with the floor?

Yes. When installed, the platform is level with the floor slab, ensuring safe and efficient transfer of materials without tripping hazards.

What installation methods are supported?

The platform can be anchored directly into the concrete floor slab or supported using braces, offering flexibility depending on site structure.

How is the platform protected against corrosion?

It features either hot-dip galvanisation (in compliance with PN-EN ISO 1461) or powder coating for strong resistance against environmental exposure.

Is the platform certified?

Yes, it has received a positive result from the IMBiGS Institute and is compliant with PN-EN 12811-3 standards, ensuring its suitability for professional construction environments.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH