WORKING AT HEIGHT – THE EVOLUTION OF WORKING STANDARDS

Working at height remains one of the most critical health and safety challenges within the UK construction industry. Despite advances in regulation and equipment design, falls from height continue to be a leading cause of serious injury and fatality on-site.

However, UK safety standards for Working at Height undergo continuous improvement, and the increase in modular product solutions creates a shift from expert-led safety equipment installations to systems that any construction site professional can easily install.

In this blog post, we will guide you through the evolution of working at height safety standards and introduce some of the most practical, modern safety systems.

WHY WORKING AT HEIGHT STANDARDS EXIST

According to a statistic by the HSE falls from height were the most common reason for fatal accidents for workers in the UK in 2024/2025. Working at Height standards exist to address the risks of working at height clearly and consistently, helping protect people on site.

The Work at Height Regulations 2005 set out a simple but effective hierarchy of control:

Avoid working at height where possible > prevent falls where work at height cannot be avoided > and minimise the consequences of a fall where risk remains.

The Work at Height Regulations 2005 are supported by product-specific British and European Standards, including:

BS EN 13374 – temporary edge protection systems

BS EN ISO 14122 – permanent means of access to machinery

BS 5395 – stairs, ladders, and walkways

HOW STANDARDS HAVE EVOLVED OVER TIME

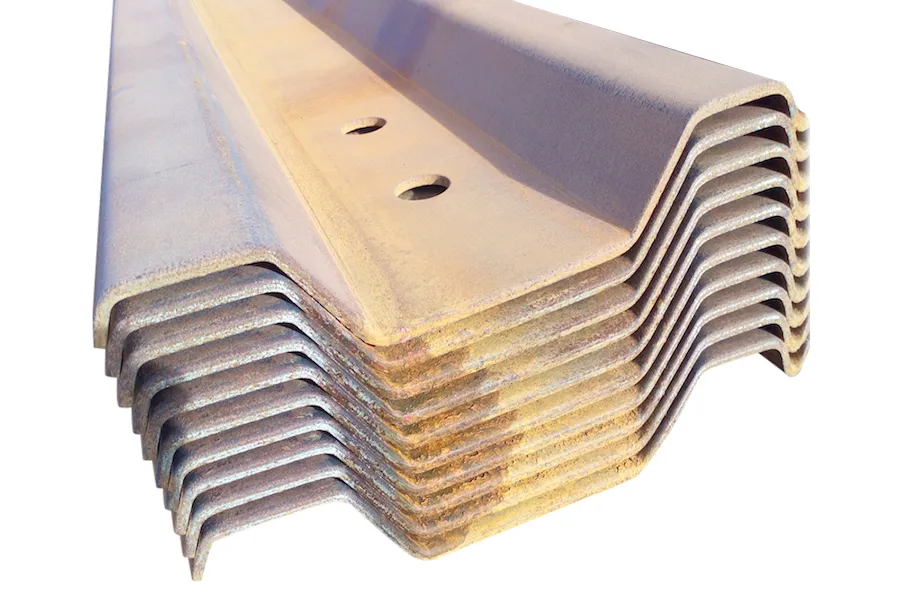

In the past, construction crews working at height often used makeshift equipment like timber rails or ladders, with safety depending largely on experience and individual judgement. Over time, this approach has been updated by the introduction of safety regulations and product-specific British and European Standards. These standards set clear requirements for strength, stability, and use of equipment and are supported by formal testing rather than assumptions.

As a result, the industry has seen a shift toward engineered solutions with clearly defined performance requirements and a growing expectation for products to show documented compliance, independent test evidence, and material traceability.

With clearly defined standards come many benefits and improvements:

- reduced risk and fewer fatal incidents,

- clear and simple compliance

- a stronger safety culture

BENEFITS OF COMPLIANT EDGE PROTECTION & ACCESS SYSTEMS

Safety training is front and centre on today’s construction sites, so most workers are familiar with the protective systems they rely on. The presence of health and safety personnel has also grown. Instead of a single officer overseeing an entire project, an increasing number of dedicated safety specialists are assigned to individual sections of the site.

Good practice on modern sites involves more than just training, it also means investing in systems that comply with recognised standards and can adapt as the project evolves.

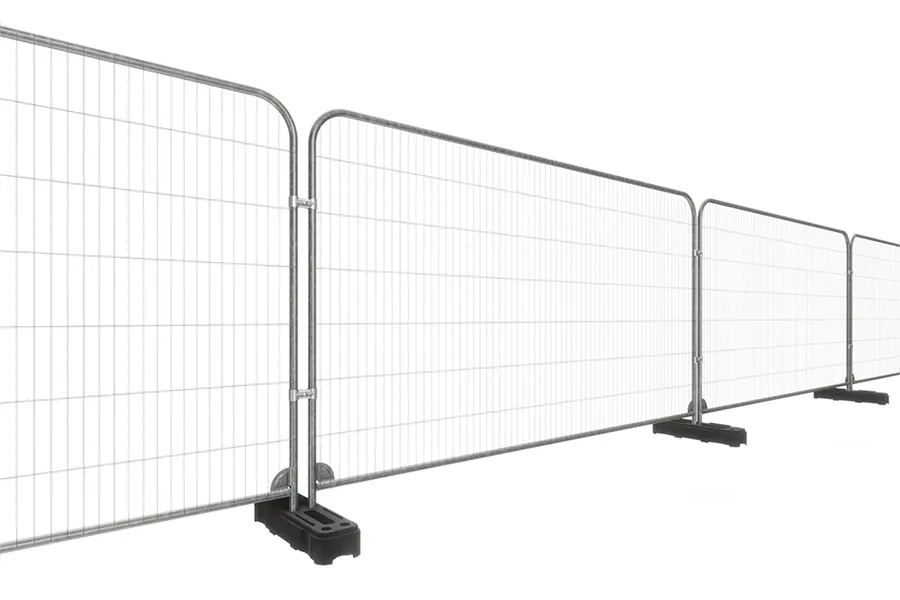

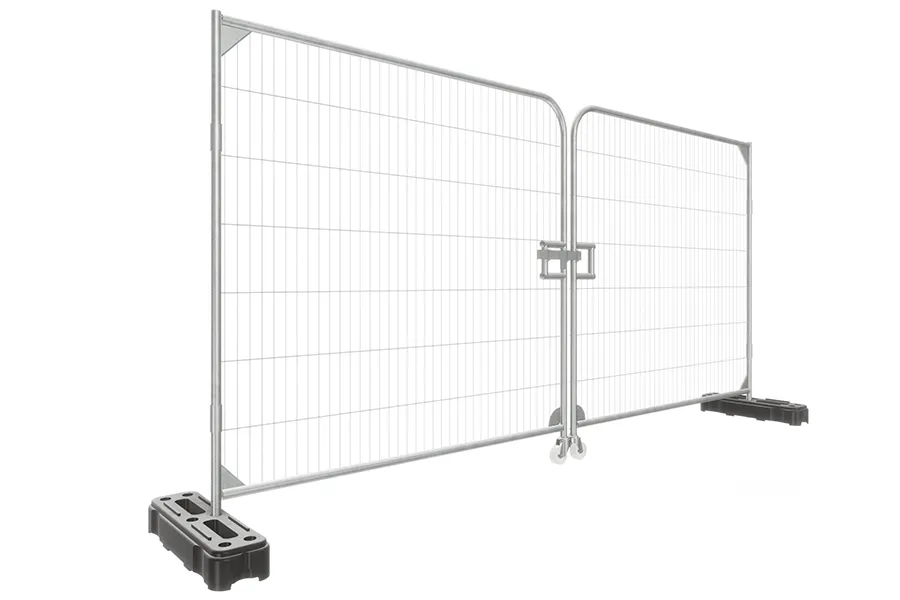

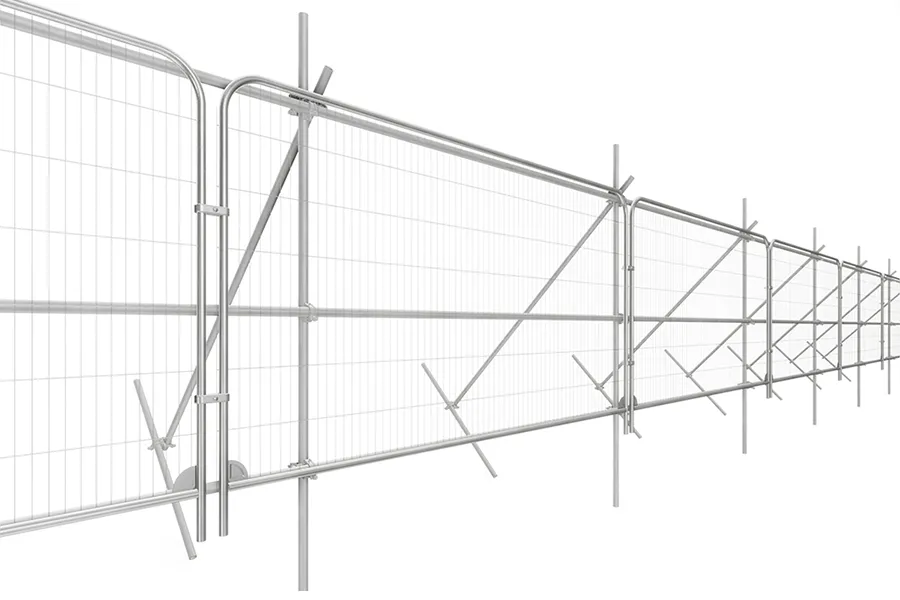

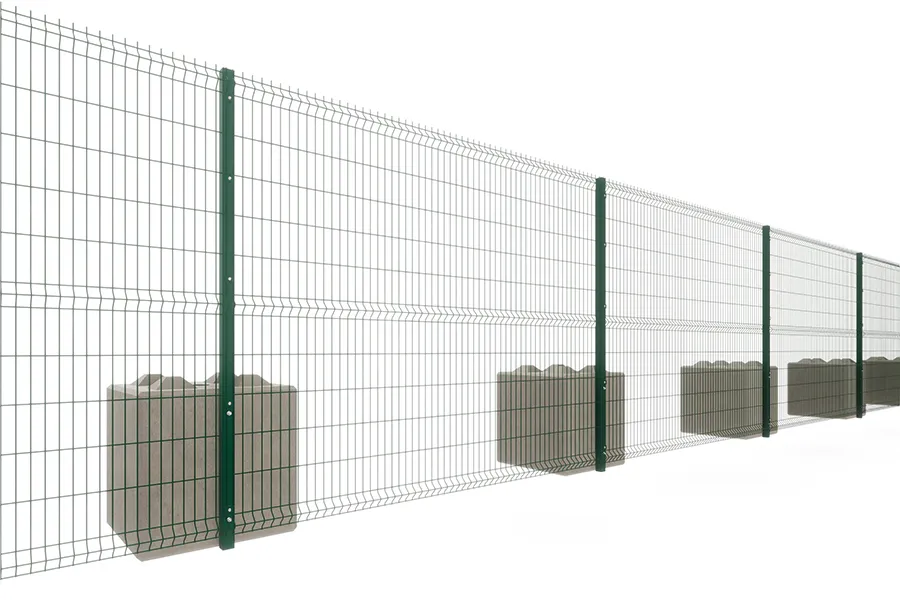

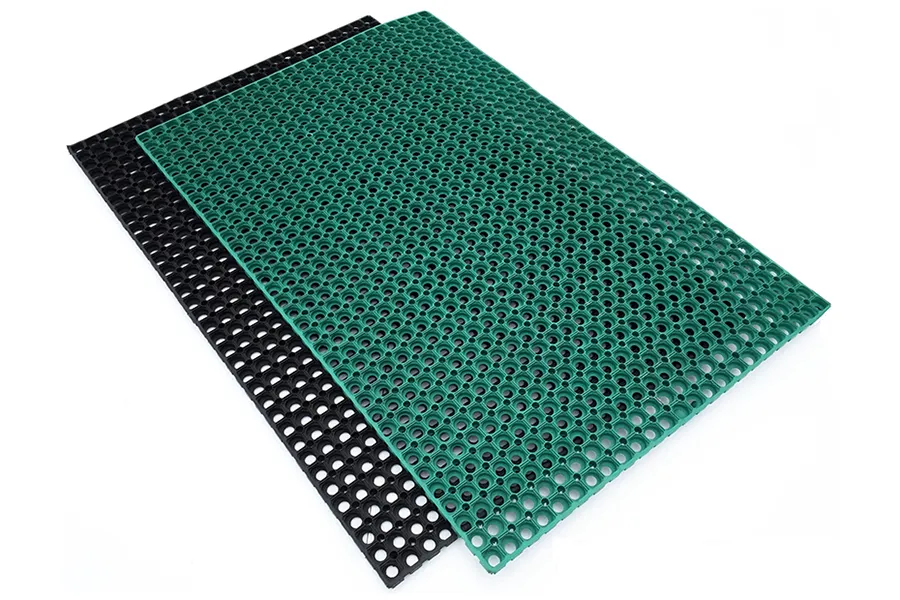

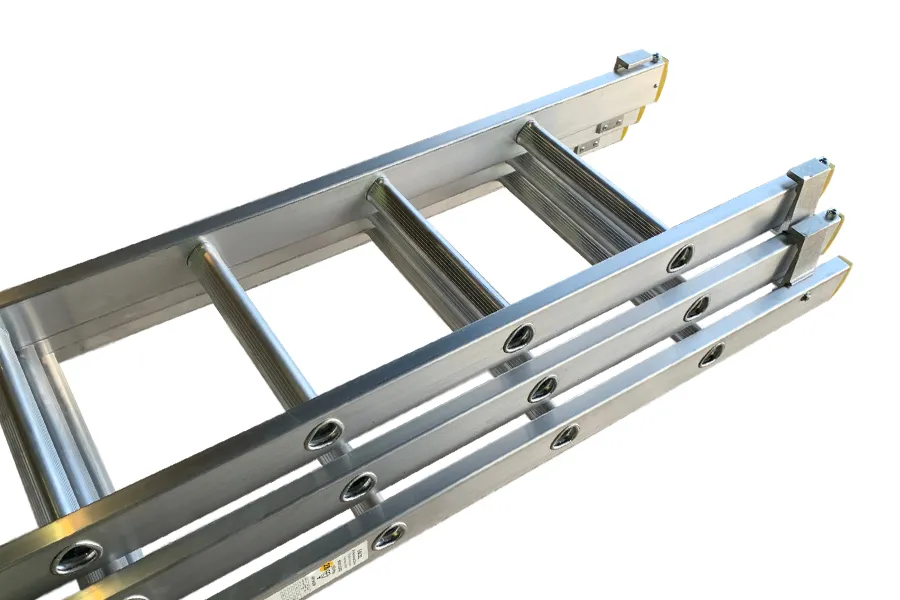

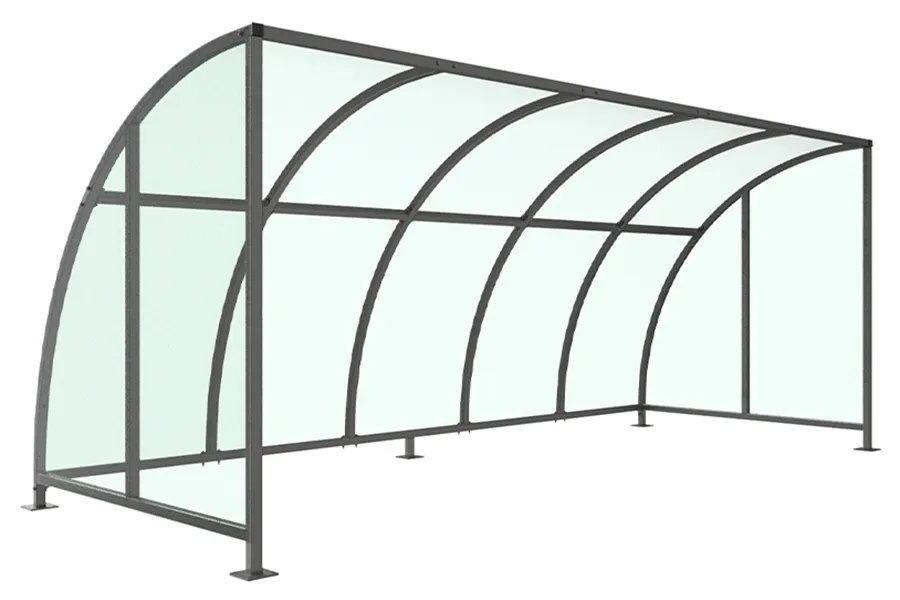

Rather than improvising with timber rails or relying on ladders, modern sites are moving towards modular systems.

This has several advantages:

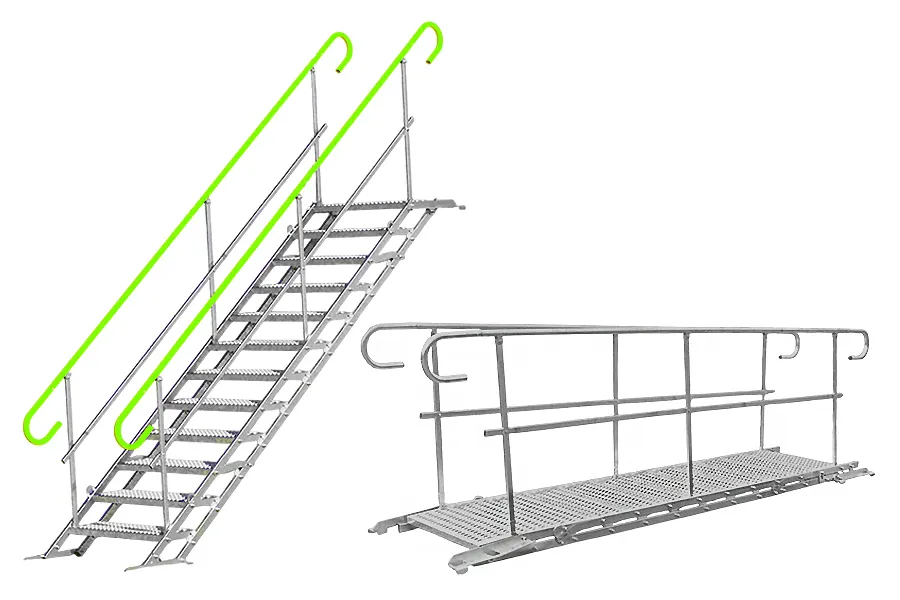

- Modular access solutions can be configured to suit different environments and layouts, offering far greater adaptability than fixed ladders.

- They are designed for straightforward assembly and maintenance. Anyone can put them together, make adjustments, or troubleshoot safely without needing a specialist on site.

Engineered edge protection and modular access systems bring practical benefits without the uncertainty of improvised solutions.

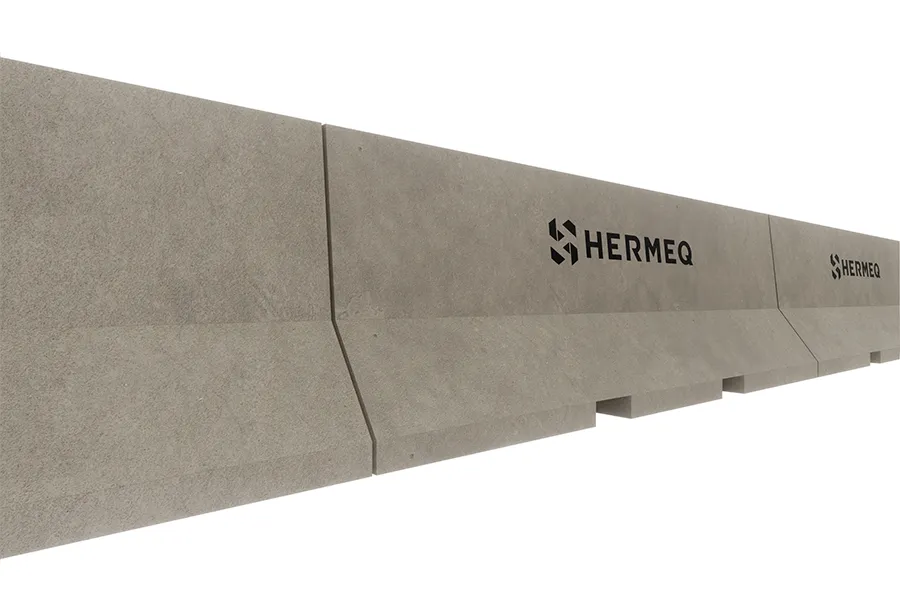

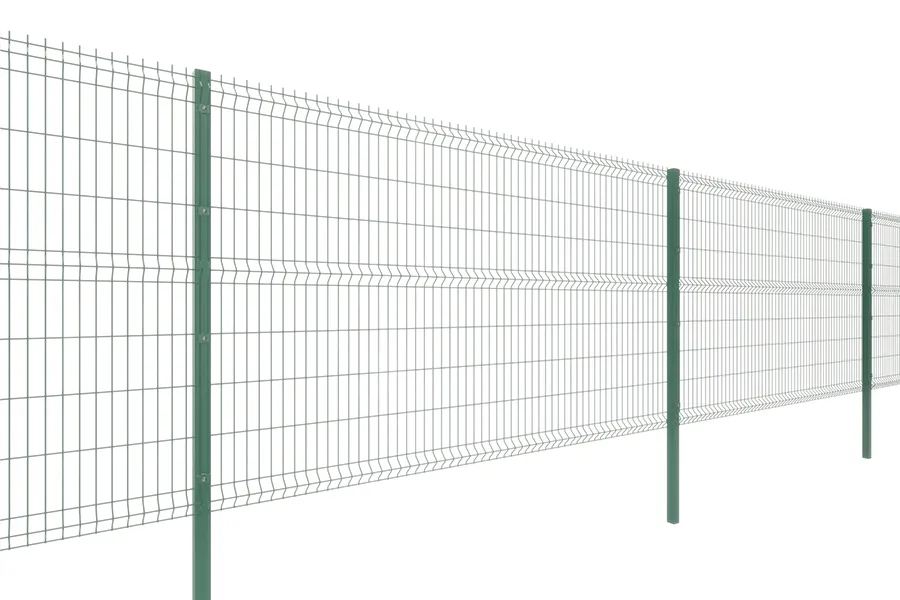

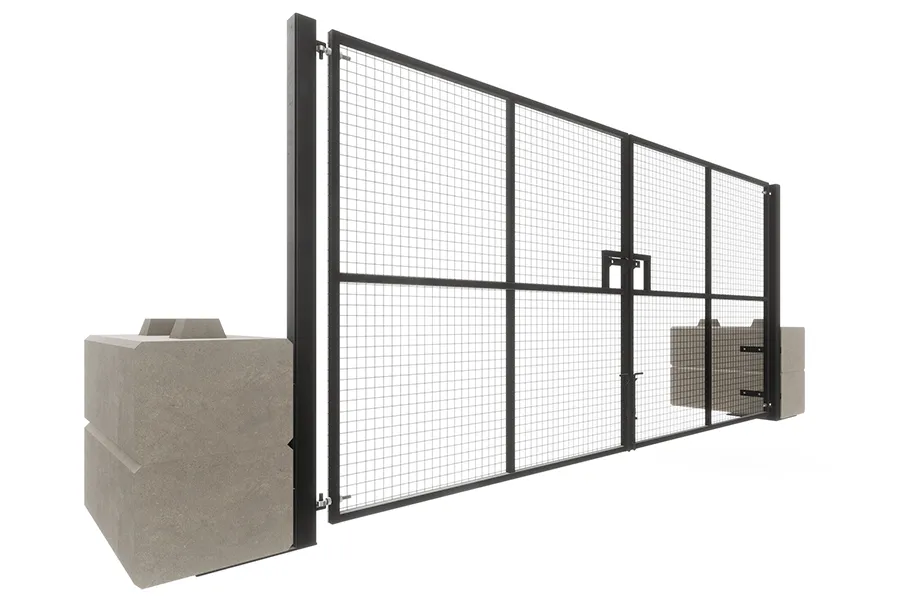

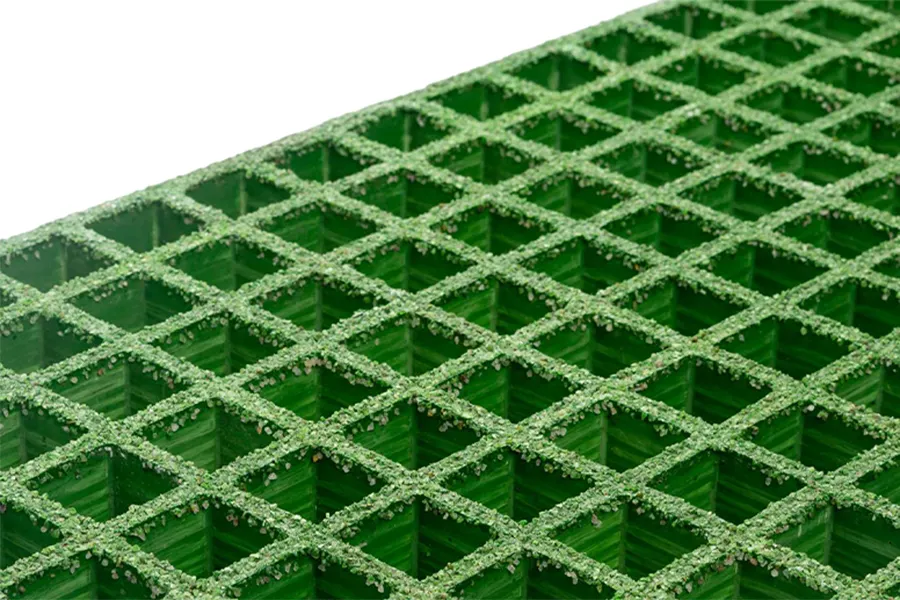

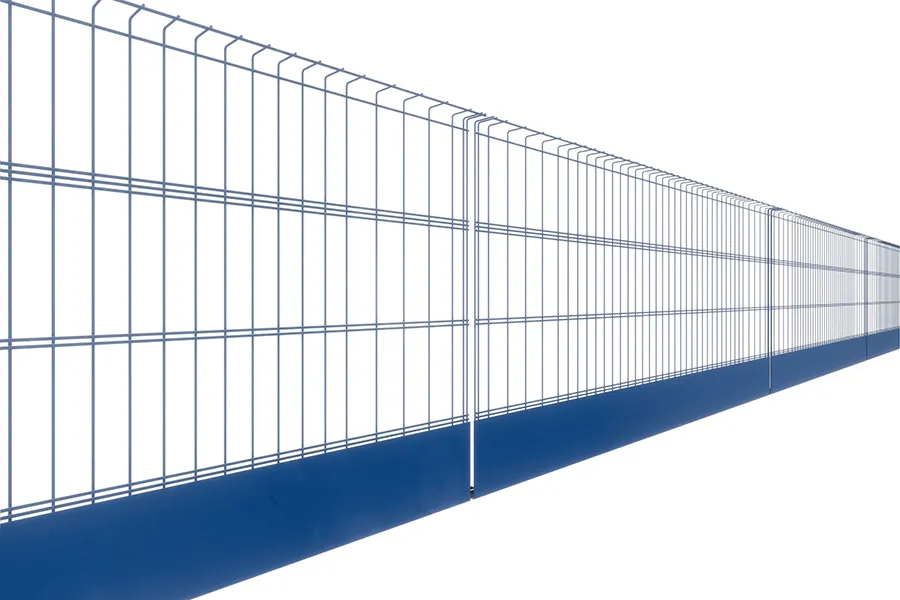

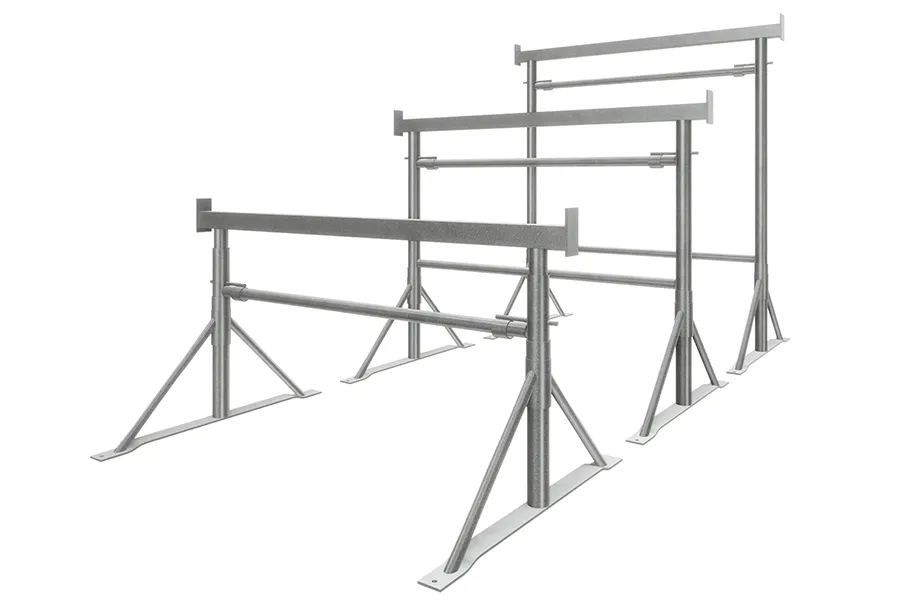

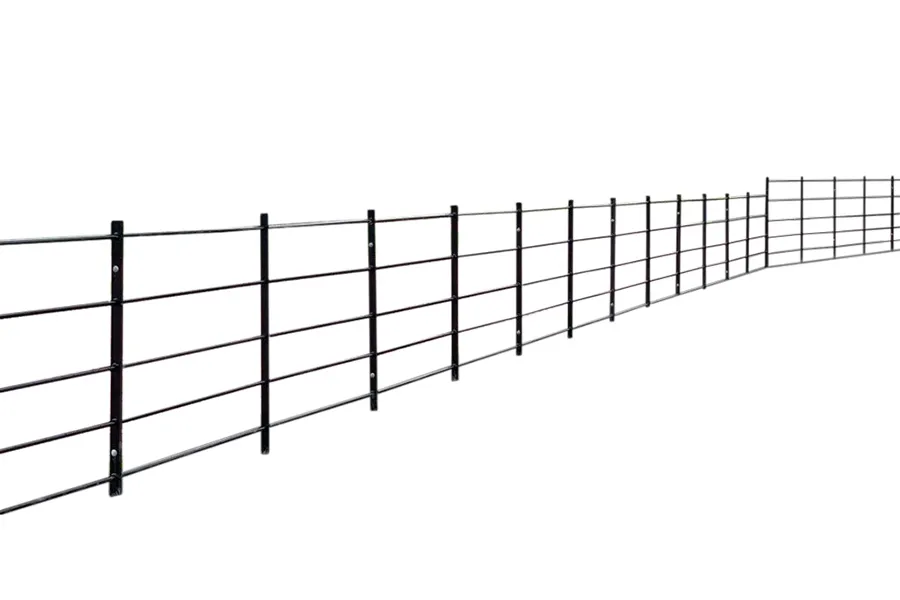

HERMEQ’s edge protection system, for example, is designed to meet BS EN 13374 Class A requirements and uses a modular steel construction that delivers consistent load performance across varied site conditions. With guardrails, midrails and toe boards, it provides continuous fall protection and helps keep site logistics running smoothly.

In the same way, modular steel stairways create a stable temporary route between levels. Adjustable heights and integrated handrails remove the need for ladders while giving crews safe, compliant access.

The modular design makes these systems simple to put together and change when needed, which saves time and simplifies documentation for audits. Solutions like these bring reliability, safety and efficiency without adding unnecessary complexity.

WORKING AT HEIGHT SAFETY IS ENSURED BY REGUALTED SYSTEMS

One of the most common questions we receive about our Working at Height solutions is:

“Are your products tested and are they compliant with the relevant standards?”

And the answer is Yes! Our modular edge protection systems and access solutions are designed and tested to comply with the latest UK regulations.

As working at height is now defined by clear standards rather than improvised solutions, investing in proven systems is essential for building safer sites and improving construction safety over time. We take pride in offering high-quality products that support this approach.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH