Drum Lifter

SKU IA5639

The Drum Lifter is the perfect device for safely and quickly lifting drums with the use of a forklift truck.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

The Drum Lifter is a heavy-duty drum lifting device that securely mounts the forks of a forklift in order to make the drum transportation device quicker and easier.

Suitable for use in a wide range of settings, the Drum Lifter is commonly used in warehousing, logistics, and engineering industries.

The process of using the Fork Mounted Drum Lifter has been made as simple as possible. Beginning with installation, the Drum Lifter is easy to mount and takes minimal time to set up.

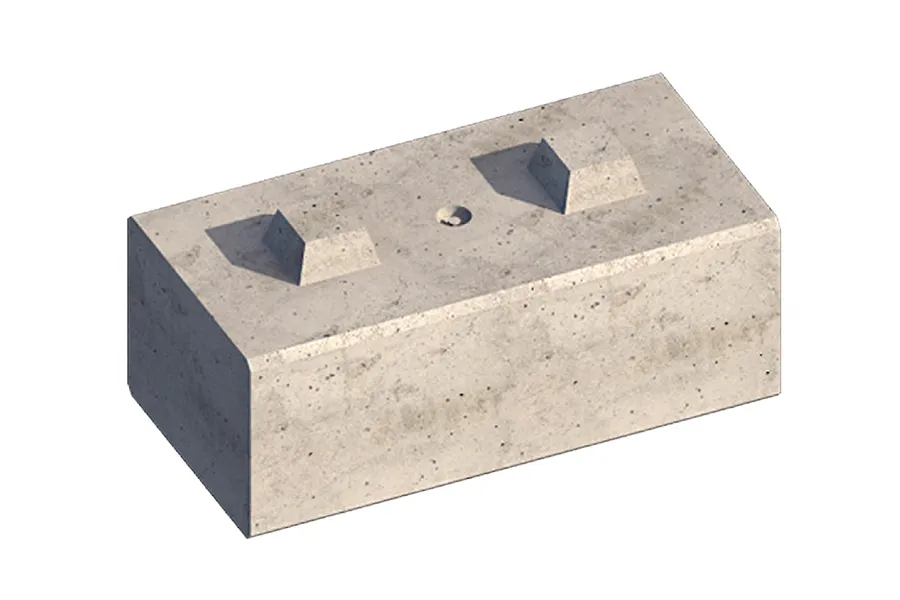

The setup process begins by adjusting the forks of the forklift truck to the appropriate distance required to fit into the fork pockets present on the Drum Lifter. The forklift forks must then be inserted into the fork pockets.

Once the forks are inside the fork pockets, the thumbscrews on the Drum Lifter must be tightened to secure the Drum Lifter onto the forklift forks. Ensure they are as tight as they should be as the incorrect installation of the Drum Lifter could cause accidents or injuries in worst-case scenarios.

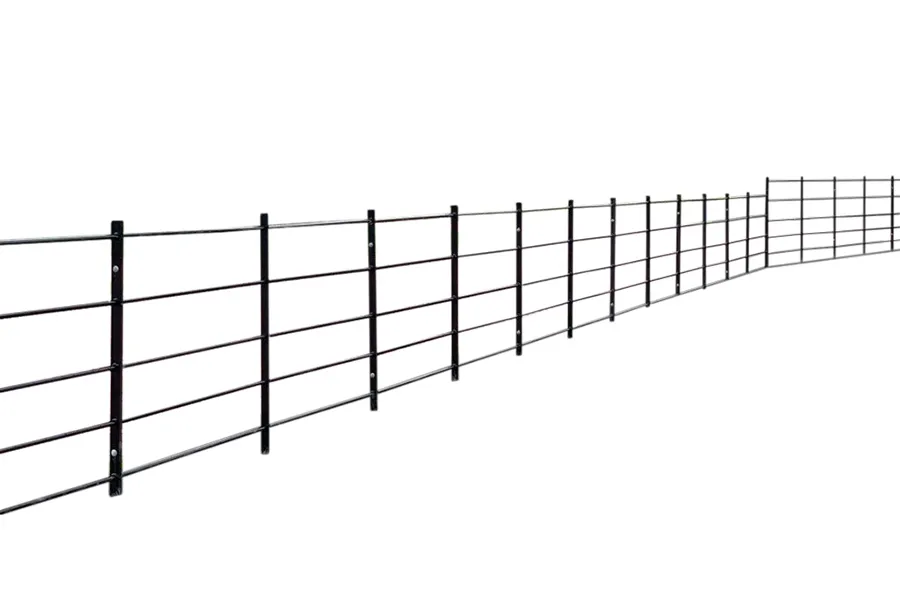

Now the Drum-Lifter has been correctly affixed to the forks of the forklift, the driver must drive towards the drum with the drum lifter arms correctly positioned between the middle two ribs of the drum.

Once the arms of the Drum Lifter are touching the drum, the driver must continue driving forwards while lowering the mast. Upon fully engaging with the drum, the mast must be raised while the forklift remains stationary.

The Drum Lifter will automatically lock underneath the top rib removing the need for the driver or others to clamp the drum in place. The Fork-Mounted Drum Lifter is now ready to lift and relocate the drum.

Once the drum is required location, it can be released by placing the drum on the floor and lowering the mast before reversing away.

To guarantee the highest levels of safety and product reliability, the following maintenance tasks must be completed regularly:

The Drum-Lifter should be checked for general wear and tear focussing on weld points, fork pockets, swinging arms, thumbscrews, and pivots.

Alongside checking the Drum Lifter for damage, the Drum Lifter must also be checked for surface rust and should be treated with proprietary inhibitors, primers, and paint regularly.

To ensure the smooth use of the pivots and thumbscrews they must be lightly regreased when required.

Any damages or potential issues with the Drum Lifter must be reported and rectified upon discovery and before using the Drum-Lifter again.

The Drum Lifter has been made with as minimal moving parts as possible to reduce required maintenance.

The manufacturer has certified the Drum-Lifter for six months from the date of manufacture. After these six months have passed, it is the customer's responsibility to have the Drum Lifter tested by the appropriate testing body.

As with any working environment, health and safety should always be the main concern. To provide the highest levels of health and safety ensuring the protection of those using the equipment the following list should always be considered:

Before using the Drum Lifter health and safety assessments should be conducted to ensure that the risks associated with using the Fork Mounted Drum Lifter and Forklift and kept to a minimum.

The forklift and Drum Lifter should also be checked to be sure they can accommodate the load being lifted.

Before lifting drums always be sure that the thumbscrews on the Drum Lifter are fully tightened so it cannot become loose and accidentally slip off.

The following actions should be avoided when operating the Drum Lifter:

- The forklift should not be driven into the Drum Lifter fork pockets without retracting the thumbscrews beforehand.

- The Drum Lifter must not be shock-loaded under any circumstances as this could easily cause accidents or injuries.

- The safe working load of both Forklift and Drum Lifter must not be exceeded as they are both manufactured to perform up to that standard.

- Personnel should always keep a safe distance from the Drum-Lifter and forklift when being used.

- The Drum Lifter should not be used to lift damaged, open-topped, straight-sided, or empty drums.

- When in use, the mast must remain in the vertical position at all times.

The maximum fork section for the Drum-Lifter is 125 x 50 mm at 408 centres.

Only available in bright orange.

Specifications:

Drum Lifter 500kg

- Maximum capacity: 500kg

- Weight: 46kg

- C of G: 515 mm

- LLC: Fork length + 70 mm

- Number of drums: 1

Drum Lifter 1000kg

- Maximum capacity: 1000kg

- Weight: 60kg

- C of G: 500 mm

- LLC: Fork length + 70 mm

- Number of drums: 2

Delivery:

Delivery times can vary and are stock-dependent. Average delivery times are between 24 hours and 5 working days.

HERMEQ stock a wide range of Scaffolding Equipment, Building Supplies, Lifting Equipment & PPE conforming to all required safety specifications and regulations. Lightweight, easy to use & made with premium quality materials in the UK!

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH