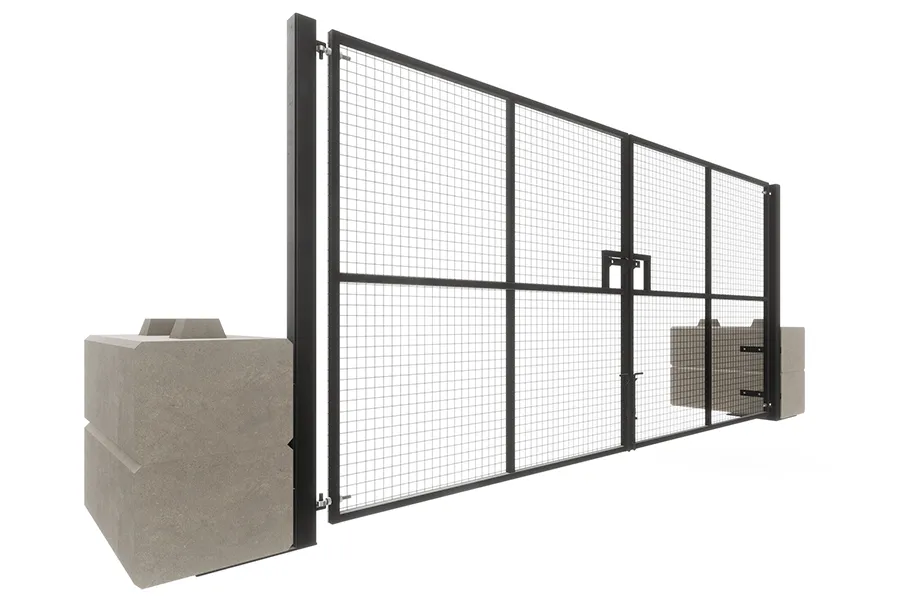

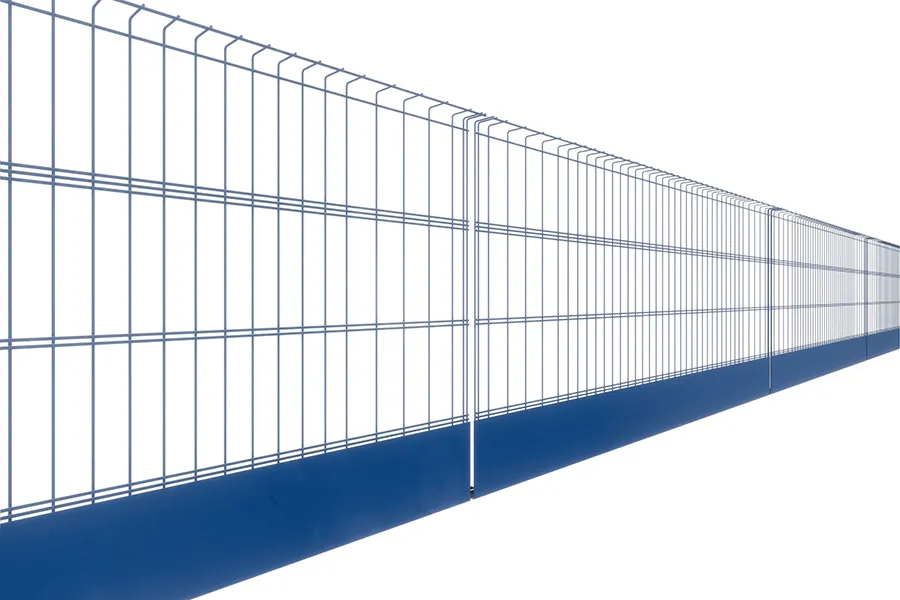

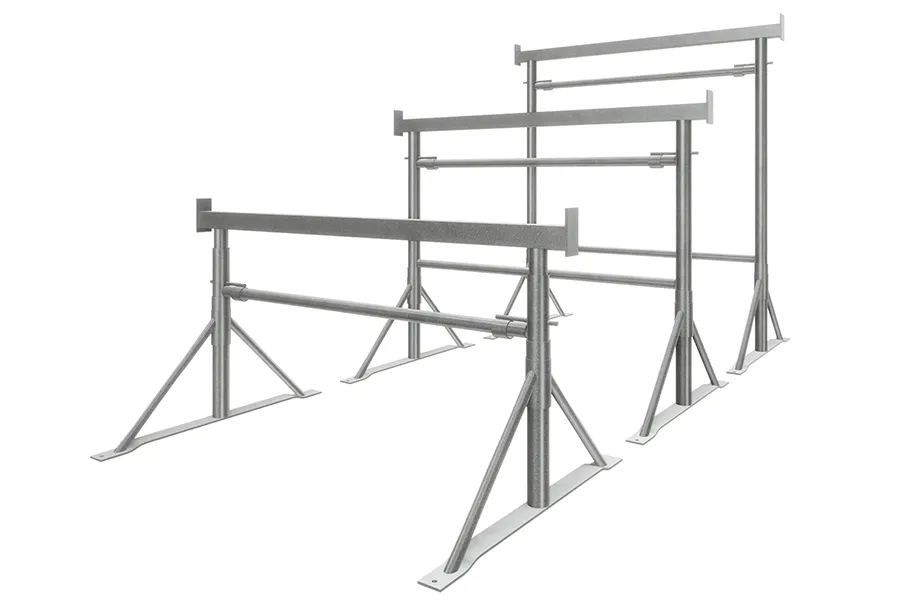

Safe Hoarding Ballast System

Product Highlights

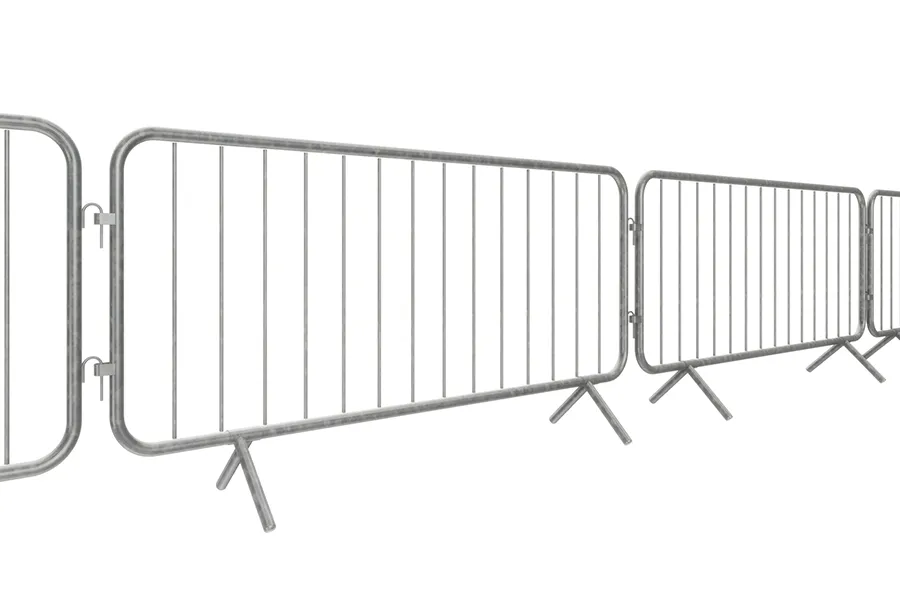

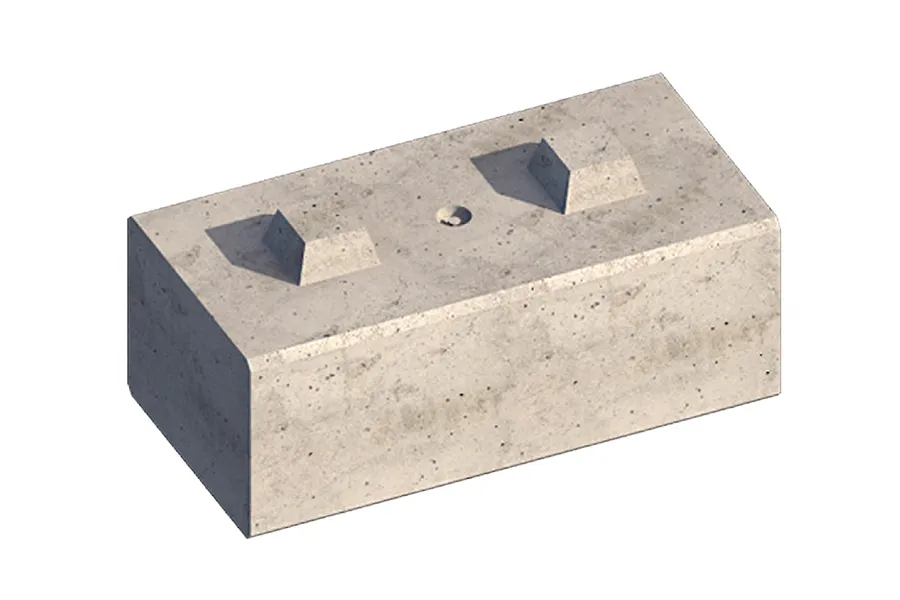

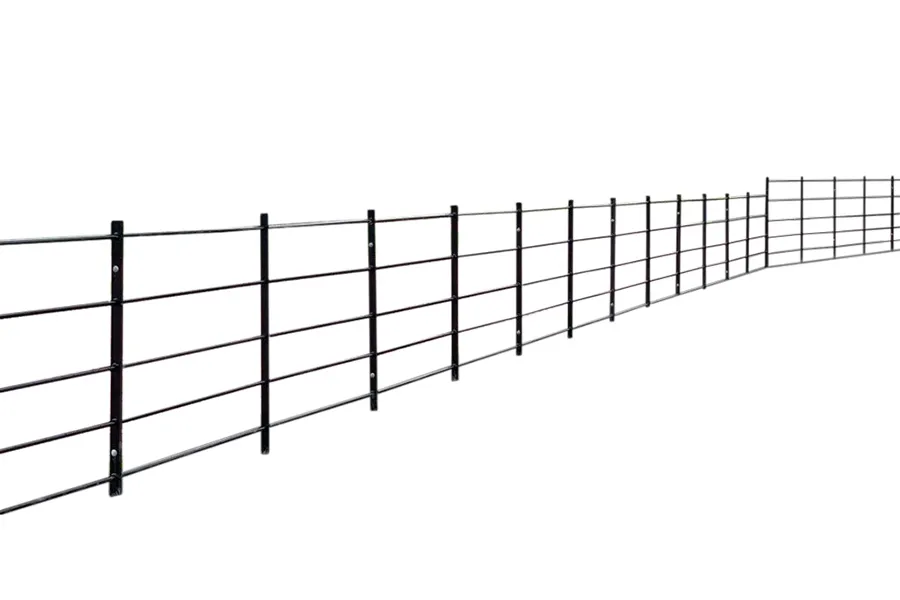

- Heavy-duty tray design - Supports hoarding panels and stabilises metal fencing.

- Anti-lift bracket included - Increases hoarding fence security and resistance.

- Compatible with uneven ground - Tray design allows easy panel alignment on all sites

SKU SS2755

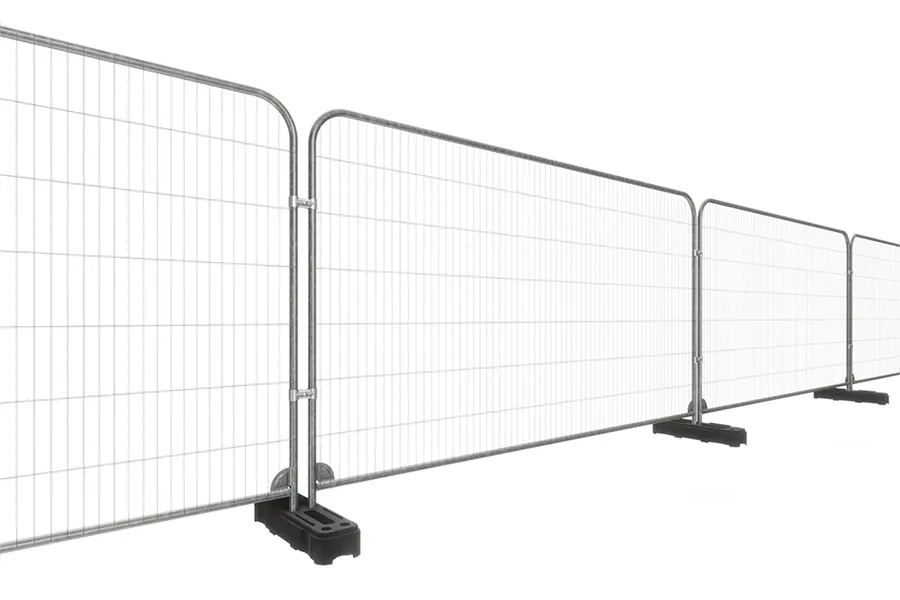

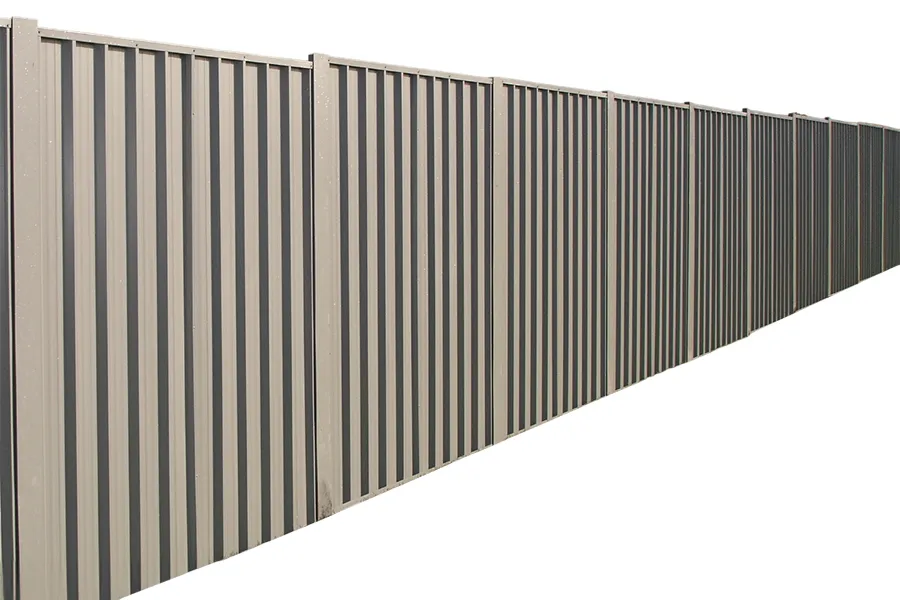

The Safe Hoarding Ballast System is designed to improve the structural stability of temporary metal fencing. Compatible with hoarding fence systems, it secures hoarding panels using a single heavy-duty tray. Ideal for construction sites using steel fence panels, it significantly increases wind resistance and safety on-site.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

Designed for stabilising steel hoarding panels, the Safe Hoarding Ballast System adds critical ballast to temporary metal fencing systems, improving wind resistance and stability on construction sites. It’s a straightforward, cost-efficient solution that meets on-site safety requirements and integrates easily with hoarding fence infrastructure.

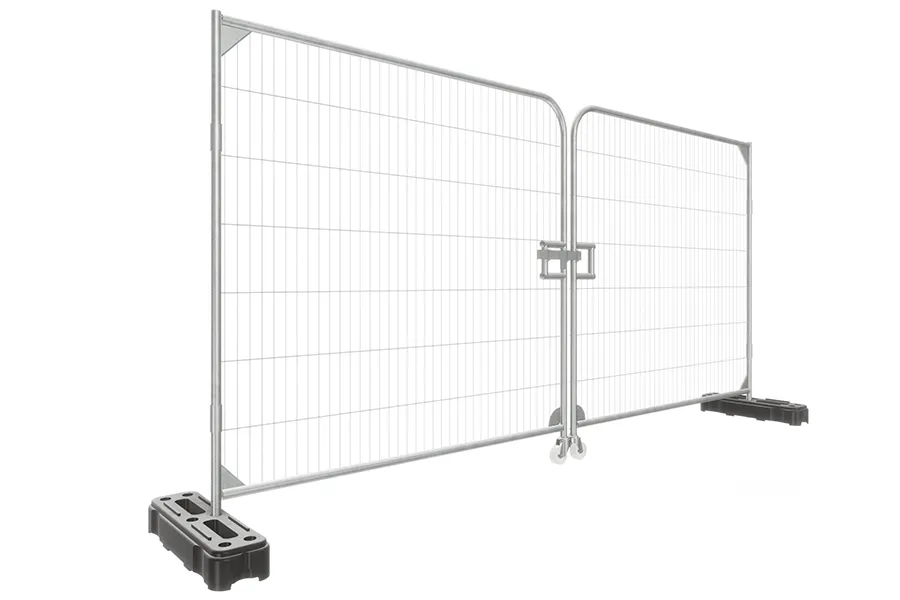

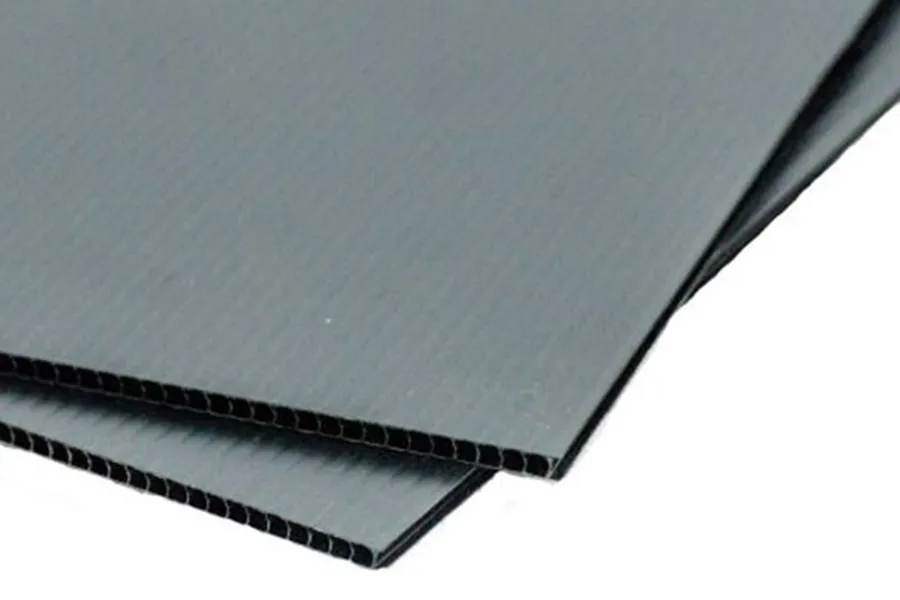

The hoarding panels slot into a stabilising tray channel, eliminating the need for rubber feet. The steel structure accommodates uneven terrain and allows precise installation. With a welded anti-lift bracket, panels are locked in place, boosting system security. Ideal for solid steel fence panels and hoarding applications. This hoarding ballast system is easy to install, saving time while maintaining high performance and robust protection in all site conditions.

- One-tray solution – Easier to install than dual-tray systems, saving labour time and costs.

- Anti-lift bracket – Welded design improves hoarding fence locking and protection.

- Stable under pressure – Adds ballast weight for better wind resistance in harsh conditions.

- Uneven ground compatible – Tray allows hoarding panels to sit flush across terrain.

- Custom temporary works – Site-specific designs available to meet compliance.

This hoarding ballast system delivers security, cost efficiency and easy deployment for short-term or semi-permanent fencing needs. Its single-tray format simplifies setup and makes it an ideal choice for quick-response projects where wind load performance is critical. Perfect for industrial zones, infrastructure works, and high-traffic commercial developments, it ensures that fencing remains secure in unpredictable conditions.

The Safe Hoarding Ballast System is especially relevant when full temporary works design is required for hoarding fence systems. The integrated anti-lift bracket removes vulnerabilities in panel stability. Unlike dual-tray alternatives, this system uses less space while still delivering exceptional load-bearing results. Its rugged steel components are built for repeated use and demanding environments where equipment must last.

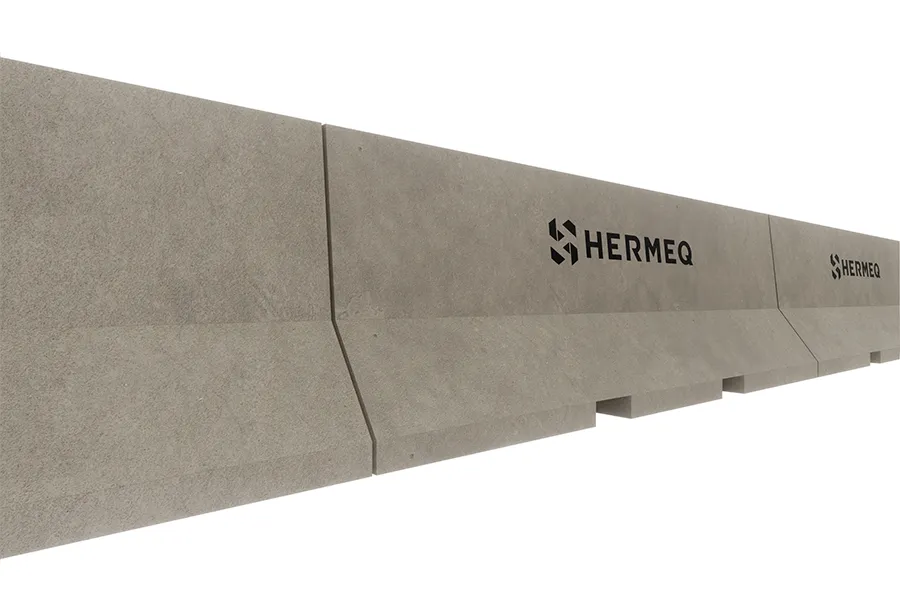

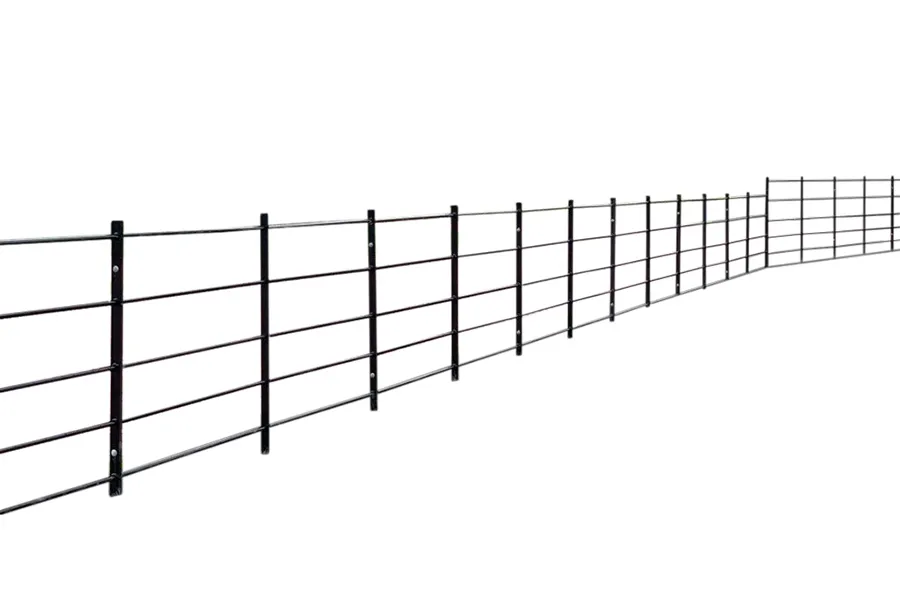

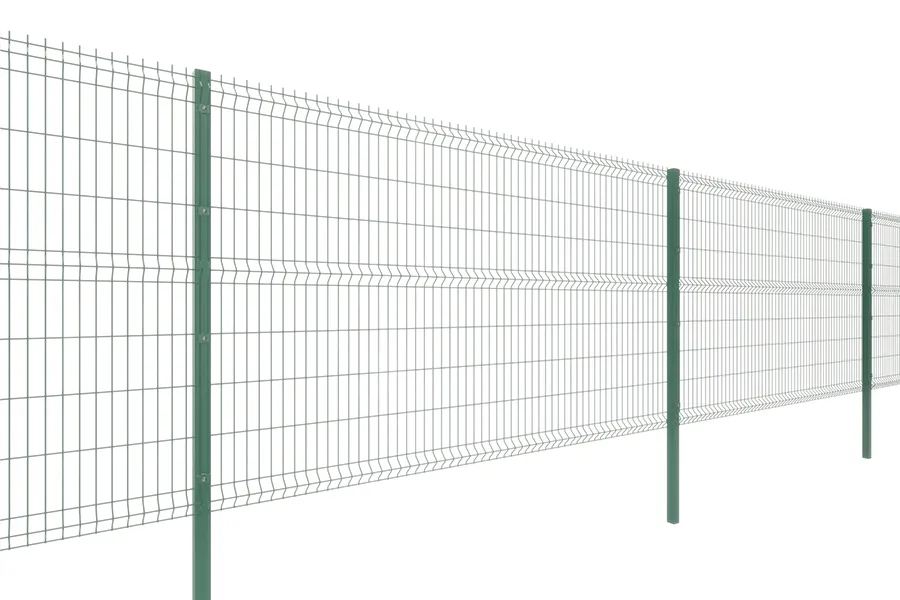

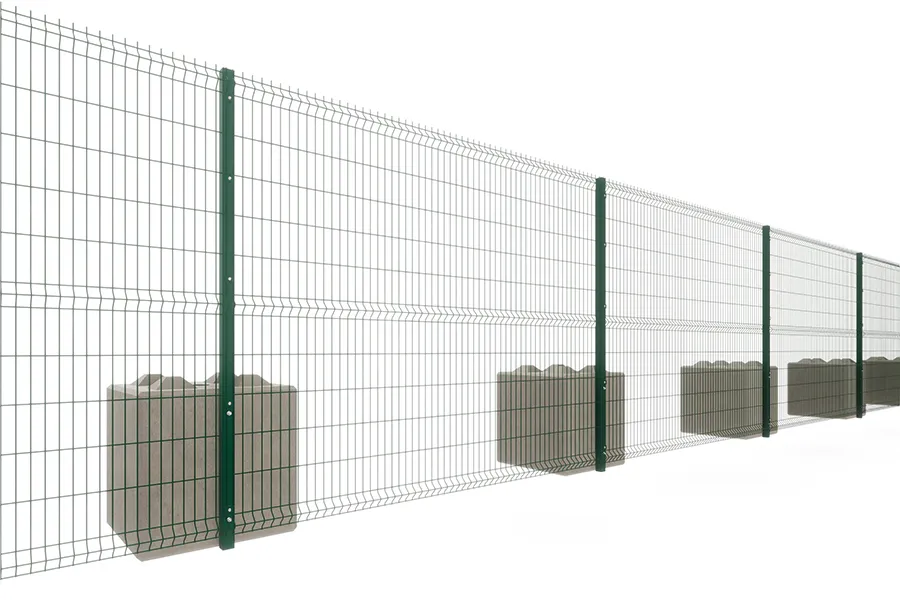

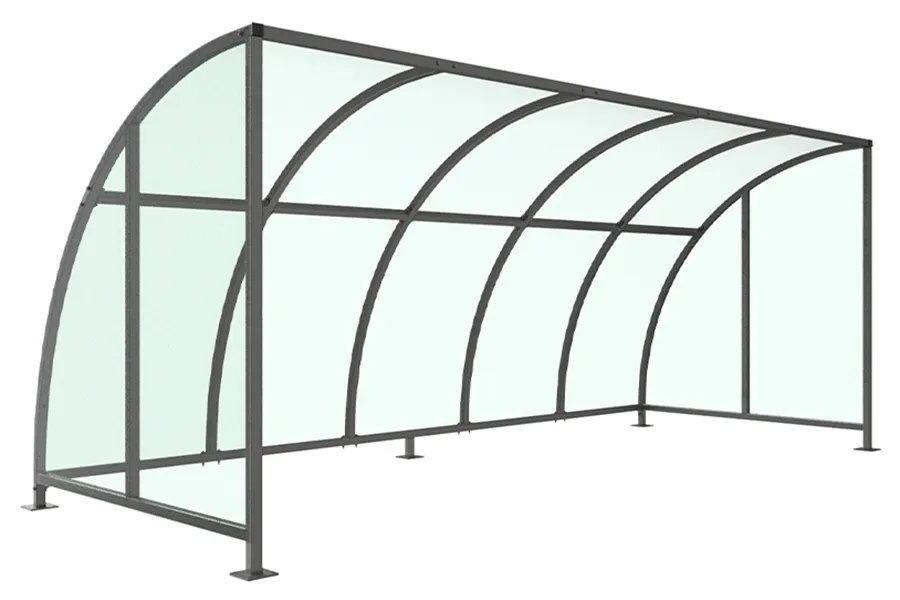

HERMEQ stock a wide-range of Steel Site Hoarding, Temporary Fencing, Permanent Fencing & Road Barriers conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

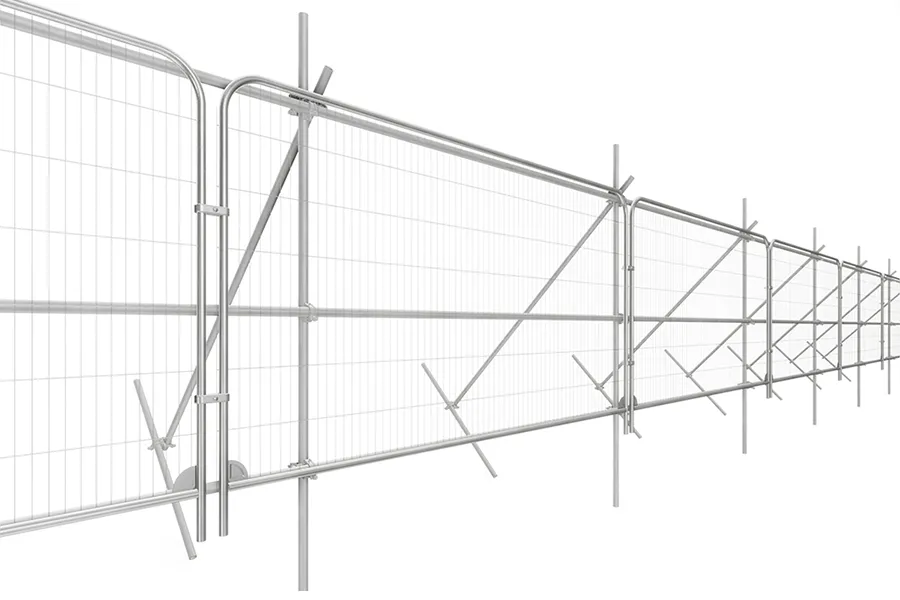

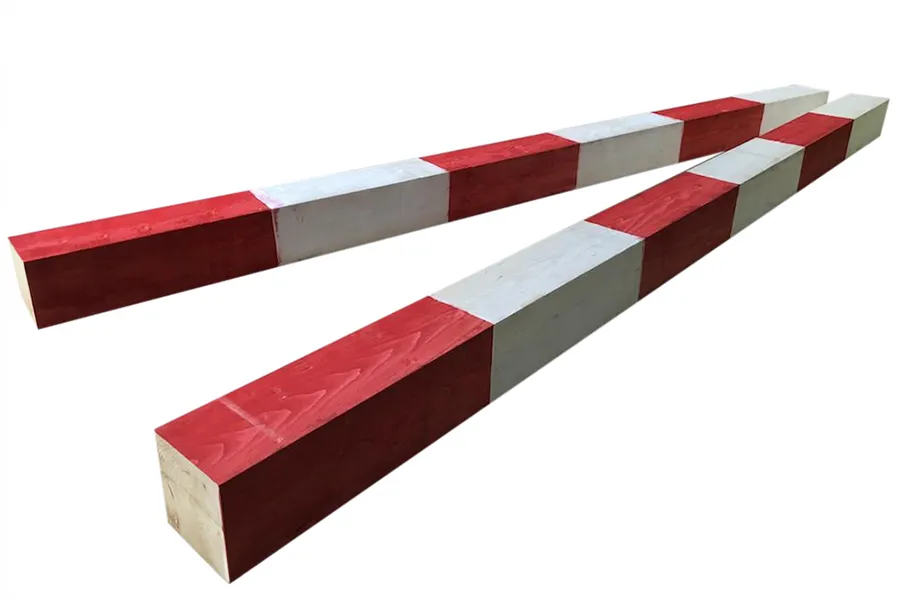

Designed with professional construction workflows in mind, the Safe Hoarding Ballast System is a reliable tool for any team managing hoarding fence installations on large or wind-exposed sites. Its steel base tray is engineered to house the hoarding panels at the front, creating a seamless barrier line while distributing ballast evenly across its 1300mm length.

Rather than relying on traditional rubber feet, this system features a precision-formed front channel that accepts panel bases directly, allowing quick adjustment and reducing risks on uneven surfaces. This ensures maximum engagement with the ground and consistent line strength along hoarding panels, even in adverse weather conditions.

The welded anti-lift bracket is a crucial feature. It not only locks panels together securely but also eliminates panel uplift from wind pressure or site impact. This bracket becomes the linkage point for joining hoarding panels across sections, offering additional rigidity to the overall metal fencing solution.

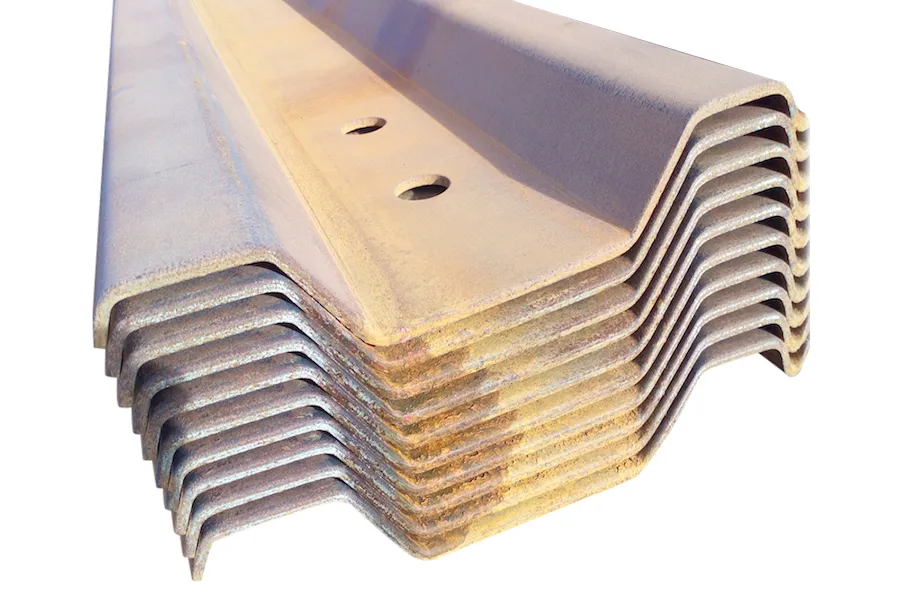

The system includes:

- 1 x Heavy-duty block tray (solid steel, self-colour)

- 1 x Anti-trip front channel with anti-lift bracket (painted black)

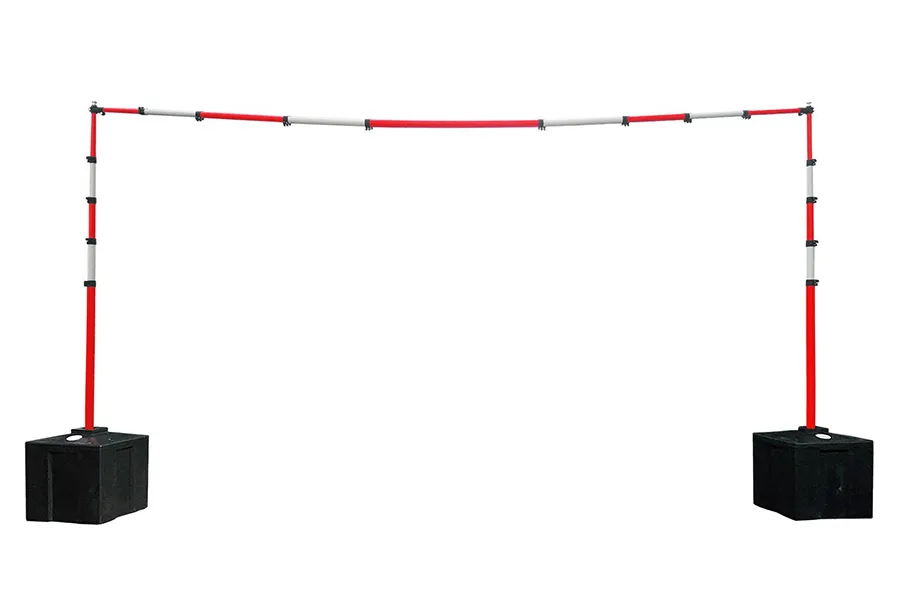

- 1 x 2.1m galvanised stabilising arm

Construction firms frequently use this system in conjunction with our Steel Hoarding Panels for forming perimeters around high-security zones, excavation works, or hazardous areas. Its compatibility with temporary works designs also ensures peace of mind during inspections or compliance reviews.

On high-wind sites or where pedestrian interaction is frequent, this hoarding ballast system forms an integral part of site safety strategies. Ballast can be added or reduced depending on conditions, offering adaptability where fixed-weight systems fall short. Labour savings and reduced install complexity also provide tangible commercial benefit across repeat installations.

Highly recommended for use in sectors such as civil engineering, utilities maintenance, airport projects, and event site control, the Safe Hoarding Ballast System remains a core solution in HERMEQ’s hoarding range.

1 x Heavy-Duty Block Tray - Solid Steel (Self Colour) - Extends 1300mm Back From Panel

1 x Anti-Trip Channel For Housing The Hoarding Panel **Includes Anti-Lift Bracket** (Painted Black)

1 x Stabilising Arm (Galvanised) - 2.1m Long End To End

Can this system be used with any hoarding panels?

The ballast tray is designed specifically for use with HERMEQ hoarding panels. Compatibility with other suppliers is not guaranteed.

How much ballast can be added to the tray?

The system accommodates standard block ballast loads. For precise load data and design, a temporary works assessment is required.

What is the purpose of the anti-lift bracket?

The anti-lift bracket secures hoarding panels in place, preventing them from being dislodged in wind or tampering.

Can this system work on uneven ground?

Yes, the front channel allows panel adjustment, making it suitable for uneven terrain and varied site conditions.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH