HOW TO EFFICIENTLY SET UP WATER-FILLED BARRIERS

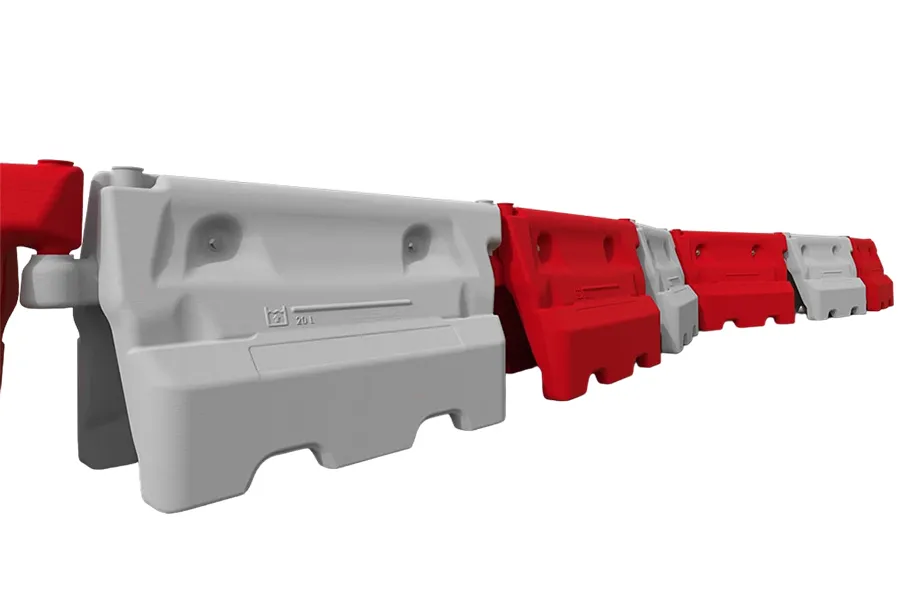

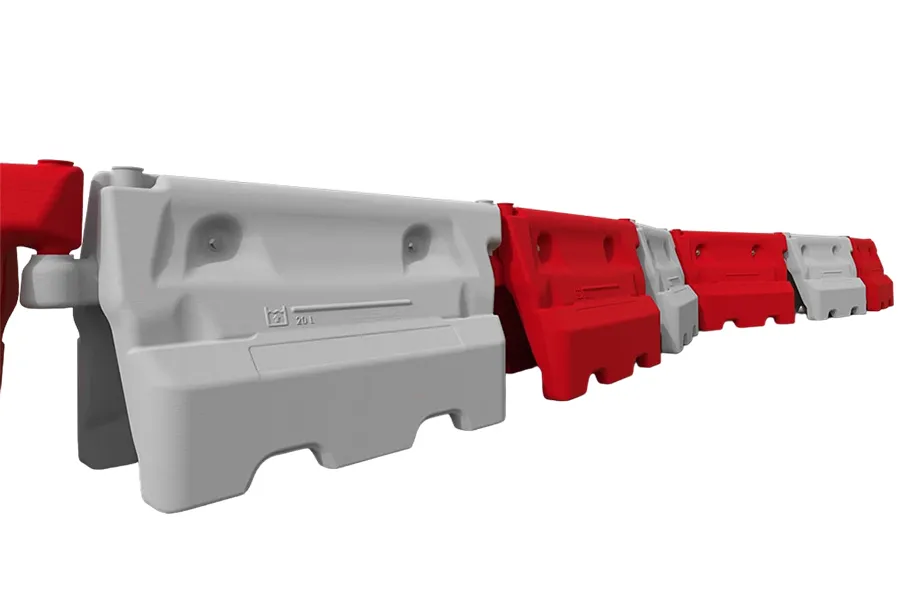

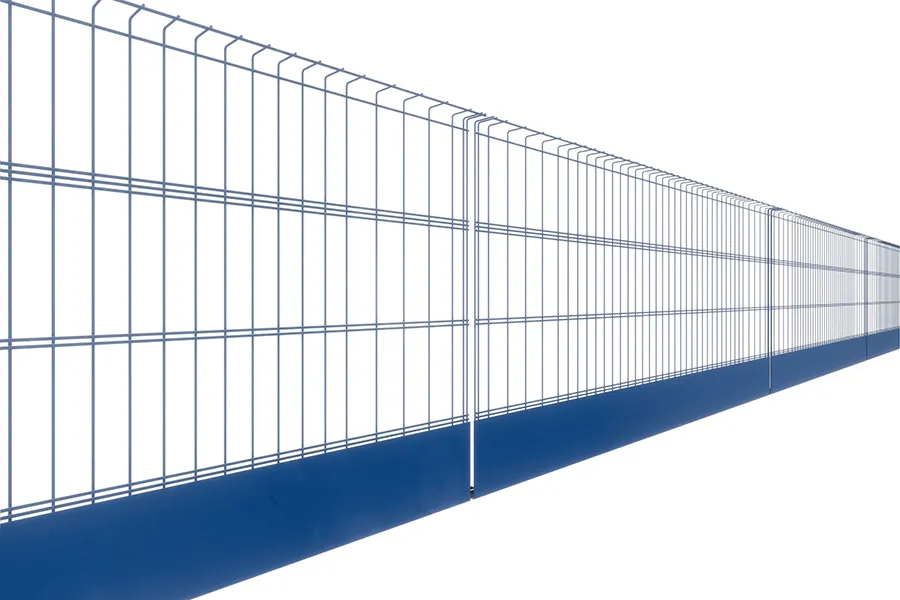

Water-filled barriers are a versatile solution for creating safe, clearly defined areas on busy sites. Made from recyclable plastic, they are connected on site and then filled with water to form a stable, temporary protective wall.

They’re commonly used to create a clear separation to allow safe movement, whether you need to separate pedestrians from moving vehicles, guide people safely through a work zone, or mark out boundaries for an event. In our last blog post, we covered the different types of water-filled barriers and how to choose the right ones for your site.

This blog post focuses on the next step: installation. We’ll take you through the setup process from start to finish, with a practical step-by-step guide and checklists to help you plan ahead, avoid common on-site issues, and ensure a smooth, safe installation.

WHERE ARE WATER-FILLED BARRIERS USED?

Before we get into the installation steps, let’s recap the three types of water-filled barriers and their use cases.

Water-filled barriers are not one-size-fits-all. Depending on the level of protection you need and what kind of environment you’re working in, you will need one of three barrier types: light-duty, heavy-duty, or crash-tested systems.

Light-duty water-filled barriers are smaller barriers with less water capacity; they are typically used in lower-risk areas where the main goal is guidance and separation rather than impact resistance. They work well for creating clear pedestrian routes and defining restricted areas on a site.

Heavy-duty water-filled barriers are sturdy barriers with a large water capacity. They are a strong option for busier sites and high-traffic environments where vehicles operate near pedestrians. You’ll often see them used for separating live traffic from construction activity.

Crash-tested water-filled barriers are heavy-duty barriers that have additionally been tested for crash safety. They are selected for higher-risk road environments where impact performance must be proven and documented. These barriers are engineered and tested to meet specific security standards, which makes them suitable for use on motorways.

Once you have chosen the correct barrier for your site, you can start preparing for a smooth installation.

KEY THINGS TO CONSIDER BEFORE INSTALLING WATER-FILLED BARRIERS

- Conduct a site survey in advance to support a smooth and successful installation.

- Check ground conditions. This is important for delivery access, installation and effectiveness of the barrier. Make sure the barriers are positioned on ground that can be accessed by delivery vehicles and water tanks, and that the ground is level and firm so they can be aligned and connected correctly.

- Arrange a water tanker for installation day. Especially for larger barriers, which can take several hundred litres of water, filling can take a long time, and a standard hose may not be sufficient.

- Review site access to ensure it can accommodate both the delivery vehicle and the water tanker.

- Allow adequate installation time! A team of four can typically install approximately 800–1,000 light-duty barriers or around 400 heavy-duty barriers per day.

- Check the weather conditions for the planned installation day. Avoid installing lighter barriers in windy conditions. The barriers must be positioned before they are filled with water, and while empty, they are less stable and may be blown over in strong winds.

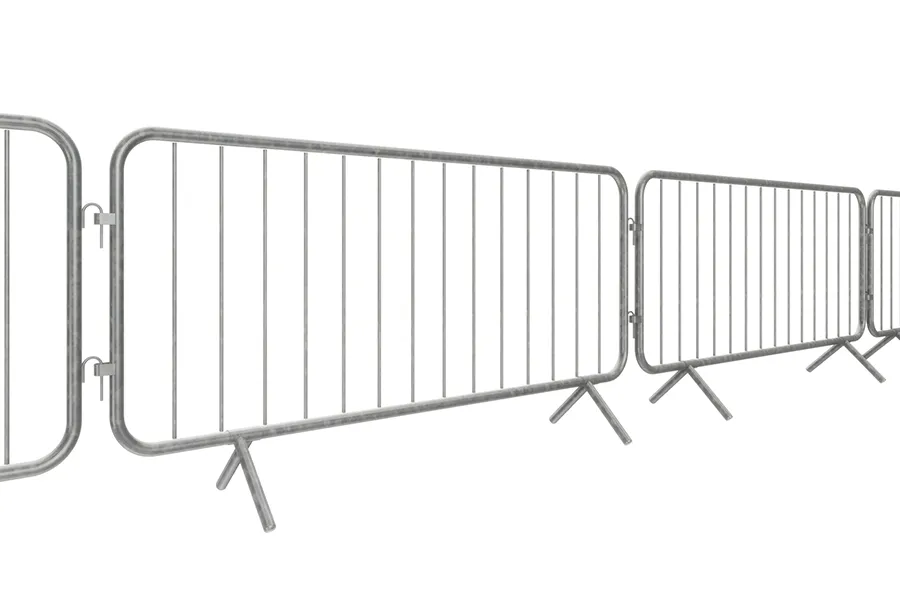

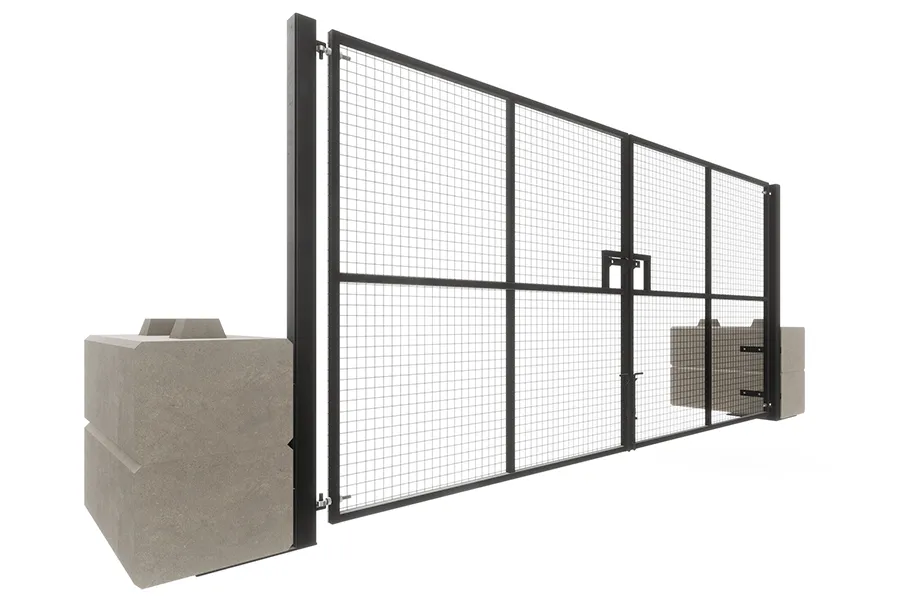

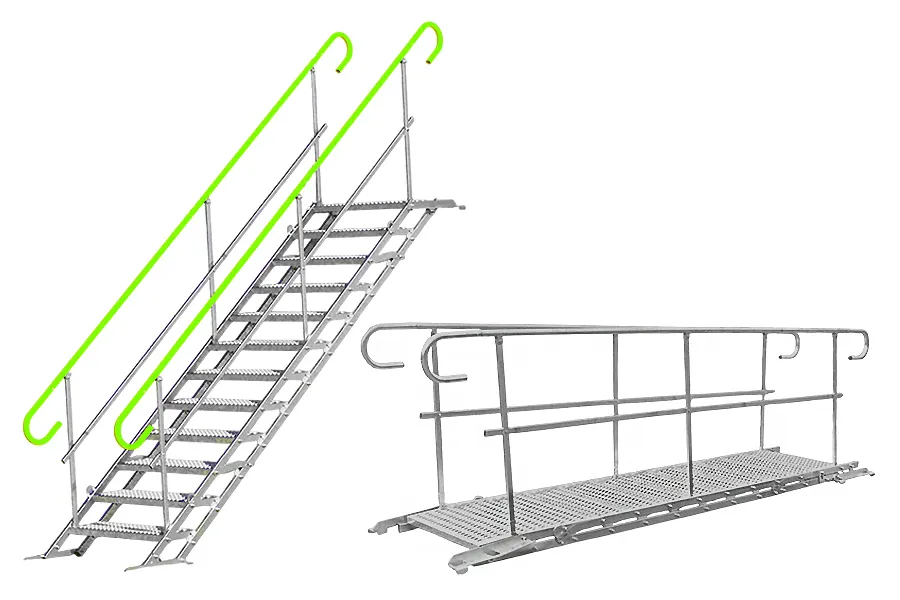

- Factor in any access gates. If you have people or vehicles that need to pass through the barrier wall, factor in where suitable access gates for vehicle access or pedestrian access need to be placed when planning your installation.

STEP-BY-STEP GUIDE TO SETTING UP YOUR WATER-FILLED BARRIERS

Once you have chosen the right barrier and considered your site conditions, you are on your way to a smooth installation. To help you prepare, we have created a step-by-step setup guide for both regular and crash-tested barriers.

Setting up light-duty and heavy-duty water-filled barriers

Step 1: Offload the barriers close to the installation line

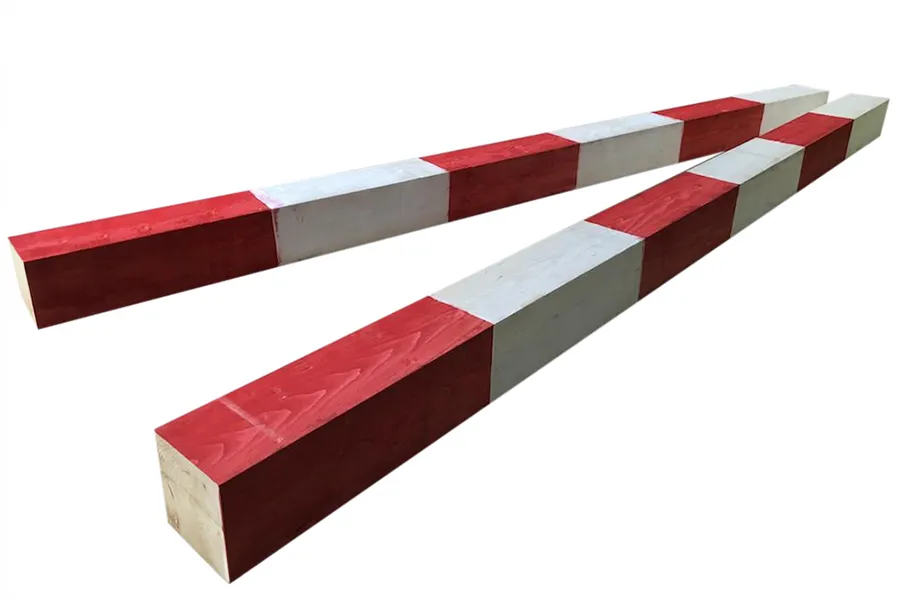

Unload the pallets from the delivery vehicle and place them as close as possible to where the barrier line will be installed. This reduces manual handling and keeps the setup efficient. Use suitable equipment such as a Moffett or a pallet truck.

Step 2: Position the barriers in the correct layout

Move the barriers from the pallets and place them in the planned line, following the site plan or marked-out layout. Choose a firm, level surface so the barriers sit neatly and can be connected easily. Avoid grass or soft ground if you’re using a Moffett, as it may not be safe or stable to operate. Make sure the route and installation area are clear of vehicles, plant, and other equipment so you have safe, uninterrupted access.

Step 3: Fill the barriers with water

Once the barriers are in the correct position, fill them with water. For small barriers, a standard water hose may be sufficient. However, for heavy-duty barriers or larger quantities, arrange a water tanker, as filling can take a long time, and a hose may not be practical.

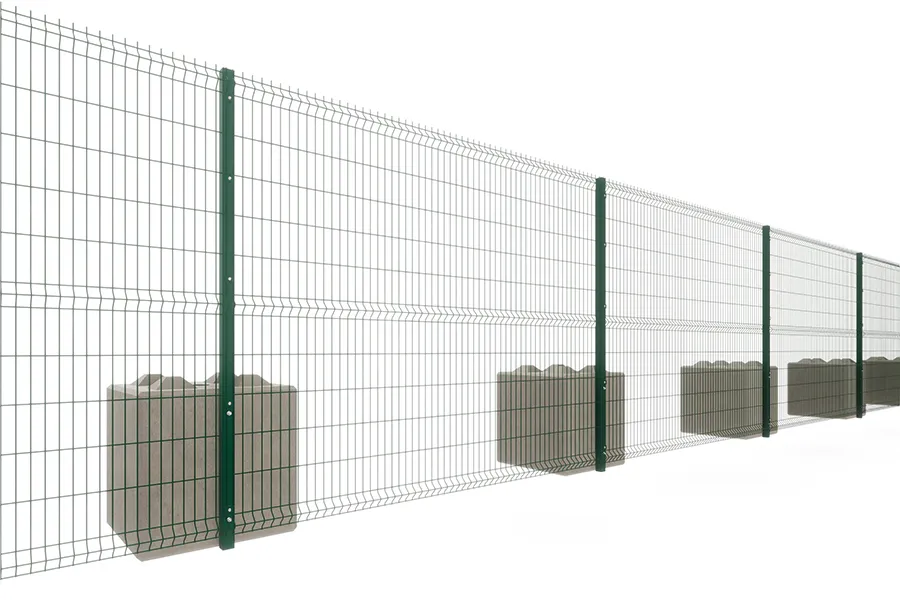

Step 4: Add extensions if required

After the barriers are positioned and filled, fit any extensions by placing them into the designated holes in the barriers. Mesh extensions for light-duty barriers and hoarding extensions for heavy-duty barriers. This should be done once the barrier line is stable and ready for use.

Setting up your heavy-duty, crash-tested water-filled barriers

Step 1: Confirm road closure and traffic management plan

Before any equipment arrives on site, ensure the road closure is in place and the traffic management setup is active and approved. On motorway projects, installation should only begin once the work zone is protected and access is controlled for delivery vehicles, lifting equipment, and the installation team.

Step 2: Prepare a safe offloading area for the delivery

Plan the unloading point so there is enough space for Moffetts to offload the barrier units safely. Moffetts typically offload from the side of the vehicle rather than from the rear, so the area must allow safe side access along the vehicle. Clear the unloading route and the working area so barriers can be moved directly into position without unnecessary handling.

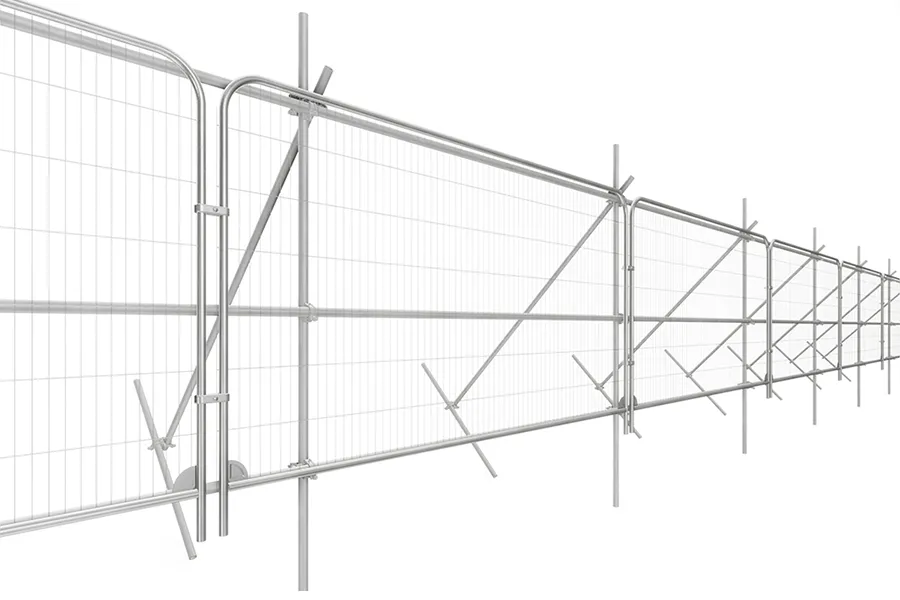

Step 3: Position and align the barriers along the marked line

Place the barriers in the correct sequence and alignment, following the site plan and the marked-out installation line. The ground surface should be suitable so the barriers sit level and stable. As you place them, push the barriers close enough together so they can be connected correctly.

Please note: It is important to do this while the barriers are still empty! Once filled, they are heavy and cannot be easily repositioned.

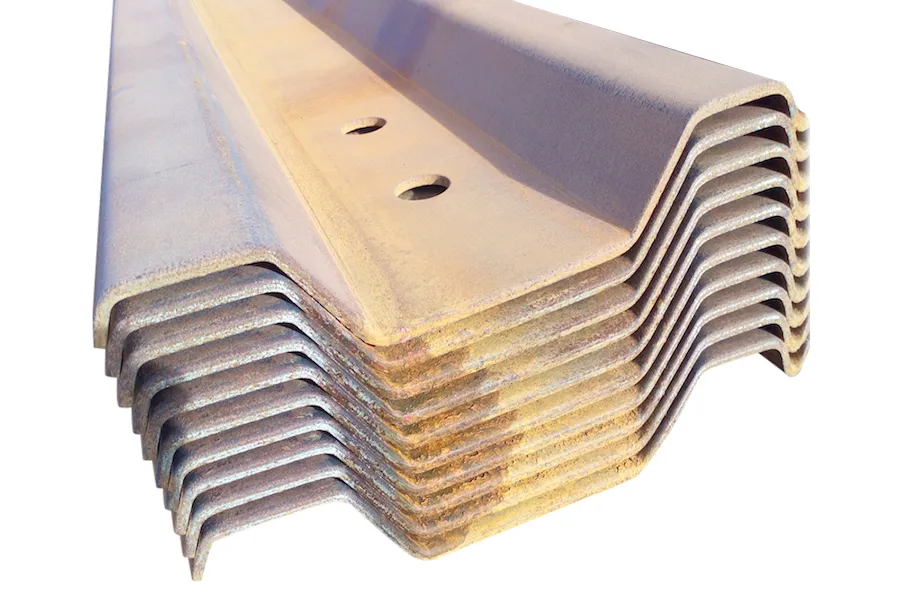

Step 4: Connect the barriers using the supplied plates and fixings

Once the units are aligned, connect them using the system plates and bolt fixings. There is only limited tolerance, so the barriers must be pushed together before the plates can be fitted and bolted. Make sure the plates are on site before the installation starts (they should be included in your order).

Step 5: Fill the barriers using a water tanker

After the barrier line is in position and connected, fill the units with water. For motorway-grade heavy-duty and crash-tested barriers, a standard hose is not sufficient; arrange a water tanker so filling can be completed efficiently and without delays.

Step 6: Complete final checks before reopening traffic

Once filled, walk the full barrier line and confirm the units are aligned, securely connected, and stable. Check that the installation matches the traffic management plan and that the area is left safe and clear before any changes are made to the road closure.

|

Call us: |

Email us: |

CONCLUSION

Water-filled barriers are a straightforward solution for securing your site, but a smooth installation comes down to planning and good on-site coordination. If you take the time to choose the right barrier type, check access and ground conditions, and make sure the right equipment is in place (especially a water tanker for larger barriers), you’ll avoid delays and end up with a stable and secure barrier line.

And if you’d like extra support, speak to our On-Site Team to make your next setup as efficient and stress-free as possible.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH