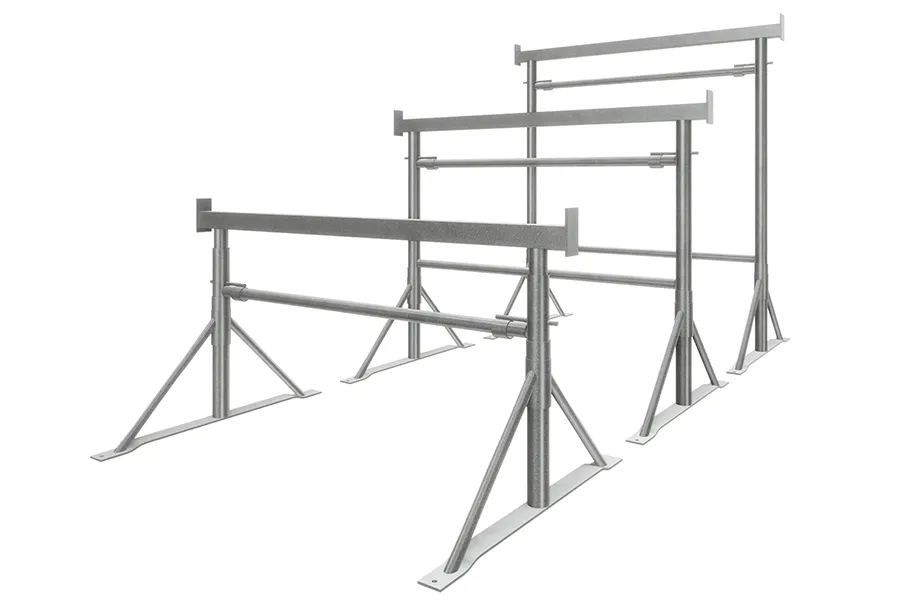

Roof Truss Jib

SKU IA5622

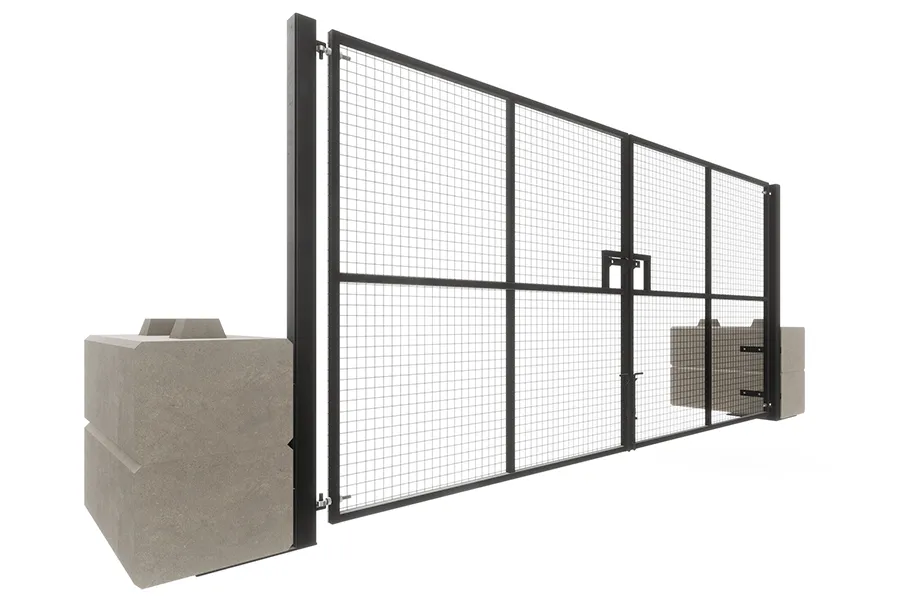

The Roof Truss Jib is a quick hitch attachment manufactured to make the process of truss placement quicker and easier.

The Roof Truss Jib has been expertly designed for the quick and easy placement of trusses, providing forward reach at heights.

The process of setting up the Roof-Truss Jib has been made as straightforward as possible for time efficiency.

Firstly, the most obvious stage of the process is attaching the RoofTruss Jib to the machine of choice, checking that it is securely in place and that there are no issues that could arise in using it.

This stage is completed by driving the machine forward towards the Roof-Truss-Jib resting on the floor and tilting the head of the truck forward in order to hook the top bar under the mounting hooks of the Jib.

The head of the truck must then be tilted backward before lifting the jib slightly off the ground. The quick-release hydraulic pins must be used in the bottom holes of the jib attachment to lock the unit into place.

Upon the completion of these tasks. the Roof Truss-Jib is ready for safe usage. In order to disconnect the Jib simply follow the same steps in reverse order.

The Mounted Truss Jib is supplied with a hook and shackle that makes the transportation of roof trusses safe and simple.

To make the Roof Truss Jib even safer, the Jib is painted in bright orange making it highly visible and easy to notice.

As with all products available via HERMEQ, the Roof Truss Jib has been rigorously tested to ensure it can perform to the standards set in the manufacturer's specification.

Over time all equipment can suffer from general wear and tear that can negatively influence the structural integrity and safety of the equipment. In order to maintain the highest performance and safety levels, the Roof Truss-Jib should be inspected weekly with the following checks being conducted:

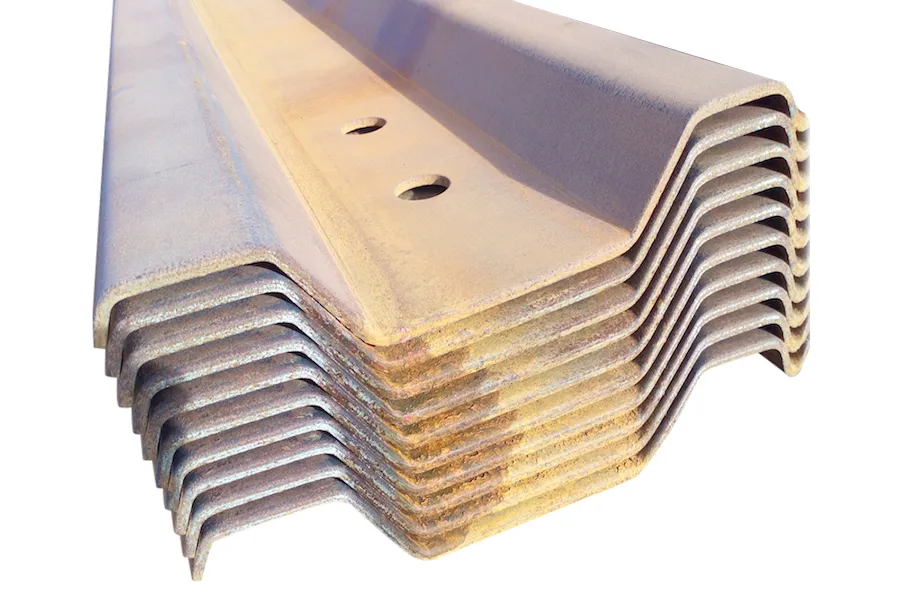

General condition checks that take into consideration all weld points, fork pockets, damaged or worn components, the swivel hook, safety latch, shackle, and the alignment and condition of the extending boom.

General surface rusting checks that are highly focused upon critical areas with the jib regularly treated with proprietary inhibitors, primers, and paint on a regular basis.

Any damages or issues relating to the jib or its performance should be reported and fixed immediately.

The Carriage Mounted Roof Truss Jib is certified for six months from the date of manufacture after which point the customer is responsible for obtaining retesting at an appropriate testing facility.

Before using the Mounted-Roof-Truss-Jib, the machine and Jib must be checked to see if they can handle the load that is being lifted and the shackle pins should be checked to ensure that they are adequately tightened. As mentioned previously the maximum load capacity for this model is 400 kg.

When using the Roof Truss Jib only verticle lifts should be made and angular lifts should be avoided at all costs, along with shock loading the jib.

Extending versions of the Roof Truss Jib are also available upon request.

Delivery:

Delivery times can vary and are stock dependant. Average delivery times are between 24 hours and 5 working days.

If you have any questions please call us on 0121 725 2338.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Load Capacity: 400 kg

C of G: 725 mm

Length: 4000 mm

Height: 1040 mm

Weight: 229 kg

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH