Fork Mounted Magnet

Product Highlights

- Efficient metal debris removal - Magnet captures sharp waste like nails and screws on site.

- Fork-mounted design - Fits most forklift forks via secure thumbscrew clamping.

- Low maintenance - Simple to clean and maintain for long-term site use.

SKU IA5642

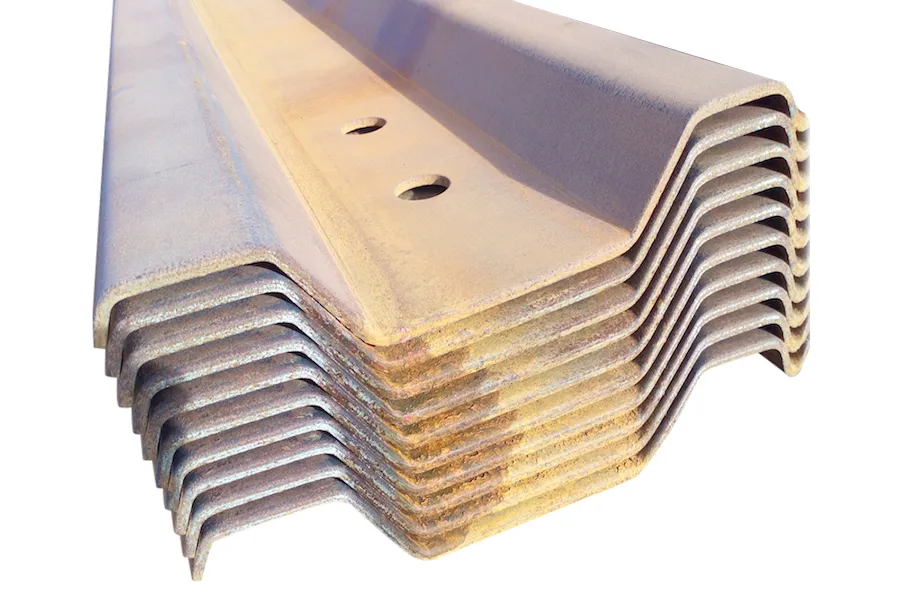

Forklift magnet designed for clearing steel debris from worksites. This industrial-grade attachment fits securely onto forks, offering efficient removal of nails, screws, and shards. A must-have forklift accessory that improves safety, reduces tyre damage, and speeds up post-job clean-up across construction, warehousing, and logistics environments.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

The Fork Mounted Magnet is a practical forklift magnet attachment used for collecting metal debris in industrial and construction environments. Designed to mount securely onto standard forklift forks, it acts as a sweeper to pick up nails, wire, shards, and metal fragments left behind on the ground. It’s a key safety forklift accessory for preventing punctures and site injuries.

Simple to install, the forklift magnet fits fork sizes up to 150 x 60 mm with centres at 683 mm. Once in place, thumbscrews lock the unit securely, making it ready to sweep. Available in two widths—1200 mm and 1800 mm—the magnet can adapt to varying workspace sizes and debris volumes.

- Perfect for removing nails, wire, shavings, and scrap metal in active work areas.

- Supports accident prevention by reducing sharp debris that could cause tyre punctures.

- Helps meet site cleanliness standards in factories, warehouses, and outdoor zones.

- Adjustable clearance allows sweeping on varied surfaces including tarmac and concrete.

- Removes steel debris faster than manual clean-up, saving time and labour costs.

Daily operation is effortless. Position the magnet around 75–100 mm from the ground, then drive slowly over the site area to collect debris. Removal of metal waste is equally straightforward: lift the magnet and use a scraper or gloved hand to clear collected material safely.

This forklift magnet is essential for operations concerned with health and safety, particularly in areas exposed to regular cutting, grinding, or metal handling. Warehouses, yards, manufacturing floors, and construction sites all benefit from its ability to reduce tyre damage and human injury from stray steel or iron particles.

HERMEQ stocks a wide range of Handling & Lifting equipment, including Forklift Attachments, Telehandler Attachments, and Lifting Cages conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

With durable steel construction and minimal moving parts, the magnet requires very little maintenance. Regular checks on weld points and thumbscrews ensure lasting service. Certification lasts 6 months from manufacture, after which customers must schedule retesting through approved providers. Two width options—1200 mm (52 kg) and 1800 mm (78 kg)—ensure flexibility across use cases.

Forklift Magnet in Construction:

On building sites, this magnet attachment helps keep paths, loading bays, and work zones free of leftover rebar shards, nails, or scrap cuttings. By clearing debris efficiently, it supports safety audits and keeps operations moving without wheel damage or foot injuries.

Industrial and Factory Use:

In manufacturing, where cut metals and shavings are a constant concern, the forklift magnet becomes a quick deployable accessory. It’s used routinely after machining, welding, or packaging to prevent workplace hazards and maintain ISO site standards.

Warehousing & Logistics:

Logistics hubs and freight yards benefit from this forklift accessory when managing pallets, crates, or metal-bound goods. Steel scrap from damaged containers or fittings is easily cleared to avoid breakdowns and HSE risks.

Operation and Safety:

Fitment is tool-free—simply slide over forks and clamp with thumbscrews. Ensure fork compatibility before mounting. All operators should conduct site risk assessments and wear gloves and goggles when removing debris from the magnet after use.

Fork Lift Magnet 1200 mm:

Width: 1200 mm

C of G: 55 mm

Weight: 52 kg

Fork Lift Magnet 1800 mm:

Width: 1800 mm

C of G: 55 mm

Weight: 78 kg

What is the forklift magnet used for?

This forklift magnet collects metal debris such as nails, screws, and shavings to prevent site damage or injuries.

How do you attach the magnet to the forklift?

Slide the magnet onto the forks and secure it with thumbscrews. Ensure forks do not exceed 150 x 60 mm.

Where can the forklift magnet be used?

It’s suitable for use on construction sites, factory floors, warehouses, and yards to maintain safe working conditions.

How do I clean off the metal debris?

Raise the magnet and scrape collected debris using protective gloves or a non-metallic scraper.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH