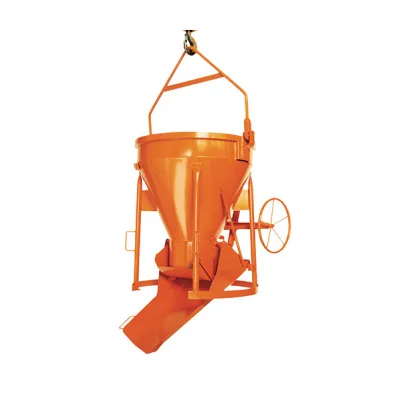

Pallet Cage

SKU EA8040

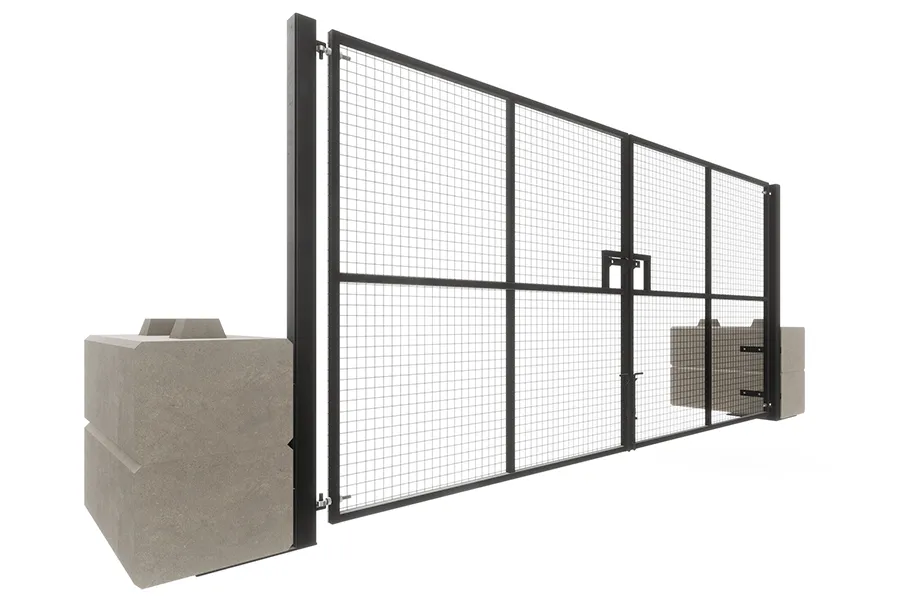

The fully enclosed Pallet Cage is the perfect choice to lift pallets without the use of safety nets and pallet forks, optimising cost efficiency and worker safety with ease.

The fully enclosed Pallet Cage is the safest and most efficient equipment to use when lifting loaded pallets using a crane.

Taking the stress out of pallet transportation, the Pallet-Cage removes the need for safety nets and pallet fork attachments as the Pallet Lifting Cage is fully enclosed ensuring that the items loaded within it are safe and secure, unable to fall out.

The loading of the Pallet Cage couldn't be simpler as the Pallet Cage features dual double doors to make the loading process as smooth as possible. The award-winning design also features load-lifting forks, full-length positioning handles, and safety screw pin bow shackles.

To begin using the Pallet Cage the cage doors must be correctly positioned in the closed position and the fork tines must be correctly positioned in their upper storage position.

Next, the lifting tackle must be attached to the shackles and the cage must be lifted approximately 1 metre off the floor before unlocking the gate locking pin.

This process should be repeated on the opposite side ensuring both gates are accounted for to avoid the gates dropping down. Once both of the gates are correctly unlocked, the gates should be allowed to hang freely.

Once these steps have been completed, one of the gates should be moved to the outer side of the cage, ensuring the gate locking eye lines up with the upper locking point before locking into the open position.

This process should then be repeated with the second gate. Now both gates are locked in the correct positions, the cage can be lowered over the top of the items that are going to be lifted.

Before lifting the pallets the area around the pallet must be checked for suitability. Only use the pallet lifting cage if the area around the pallet is flat and free of any objects, persons, or debris.

The next step is to lift the cage over the pallets that are to be lifted with the cage being controlled with the full-length grab handles, making sure the cage is correctly positioned.

After doing so, the cage is ready to be lowered over the pallet. When lowering the cage over the pallet it is important to keep an even gap between the pallet and cage walls to ensure the lifting load is evenly distributed across the surface area of the cage.

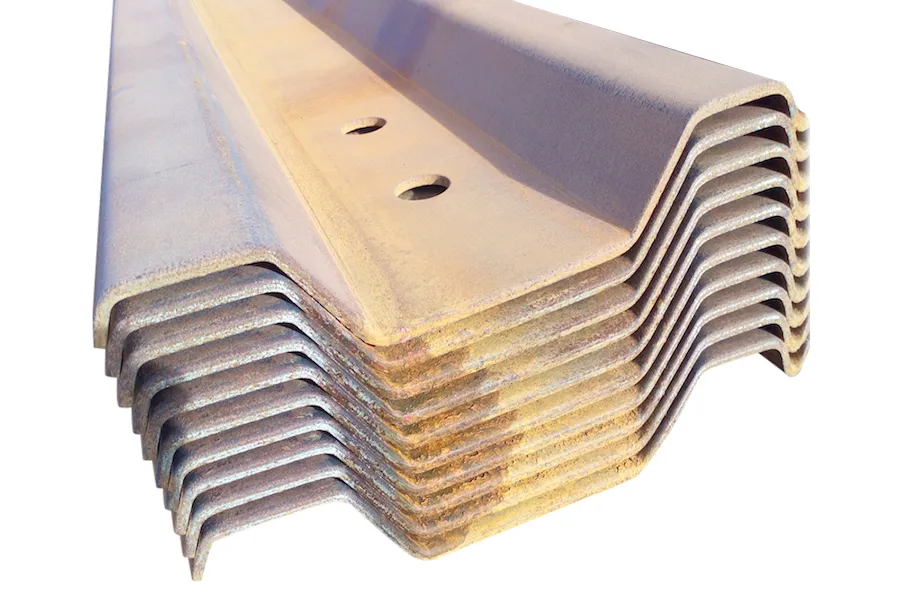

Once the cage is grounded, the load-bearing fork tines should be removed from their storage position making sure that the teeth are downward facing.

The load-bearing fork tines of the Pallet-Cage should then be slid into the cage using the fork entry points with the tines going through the underside of the pallet and out through the fork entry points on the opposite side.

After this has been completed the cage should be lifted and the load allowed to settle on the forks. This is when the cage and load should be checked to guarantee that the load is being lifted safely and the weight is distributed evenly across the cage surface.

Only once these checks have been performed should the next stage be taken. The Pallet-Lifting-Cage should then be lifted to approximately 1 metre above the ground before unlocking the cage doors, making sure to avoid the doors dropping down freely on their own before reaching the appropriate height.

When the cage has been lifted to a height that can accommodate the doors hanging without obstruction, lift one door and return it to the closed position using the two stage shot bolts. This step should then be repeated with the second door.

Once these steps have been completed, the Pallet Cage is now ready to be lifted.

Upon reaching the desired location, the Pallet Cage should be lowered until it is approximately 1 metre off the ground. Once in place, the same process of unlocking and securing the cage doors into their open position should be repeated.

The Pallet Cage should then be lowered towards the ground with the pallet sat free of the load-bearing fork tines. The fork tines should then be removed and secured back into their storage position.

Once the pallet has been positioned in the desired location, the PalletCage should be lifted up and away from the pallet. From this position, the Pallet-Cage can lift another pallet as it is already set up for pallet lifting.

When the Pallet Cage is no longer needed, return the Lifting Cage to the appropriate destination and return the doors to their closed position.

In order to remain as safe as possible when using the Pallet Cage, HERMEQ recommends wearing the following Personal Protective Equipment:

- Gloves

- Goggles

- Hard hat

- Hi-Vis clothing

- Steel toecap boots

HERMEQ supply a number of the products listed and highly recommend the Mascot Olinda Hi-Vis Trousers and the FC12 Portwest Compositelite Fur Lined Thor Boot S3 for the highest levels of visibility and protection.

Delivery:

Delivery times can vary and are stock-dependent. Average delivery times are between 24 hours and 5 working days.

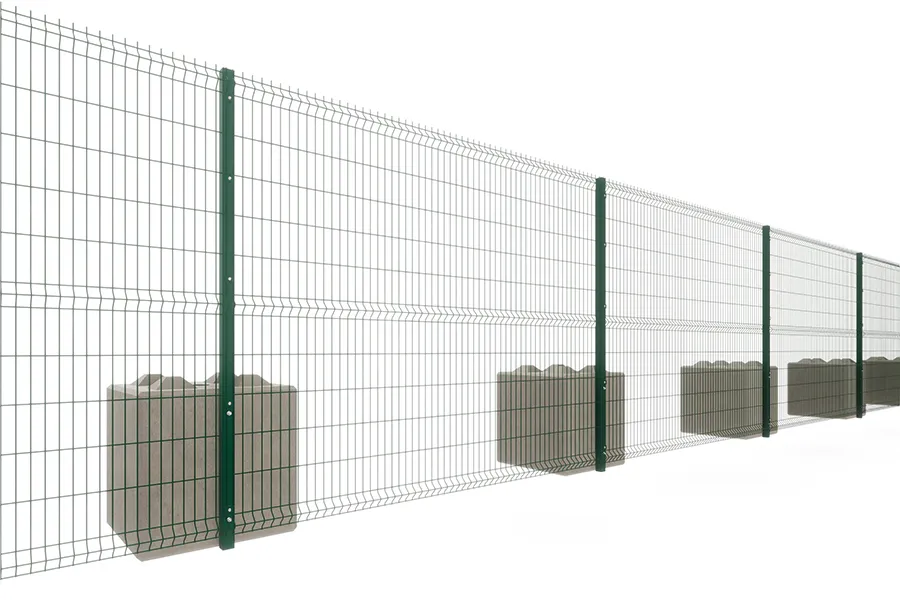

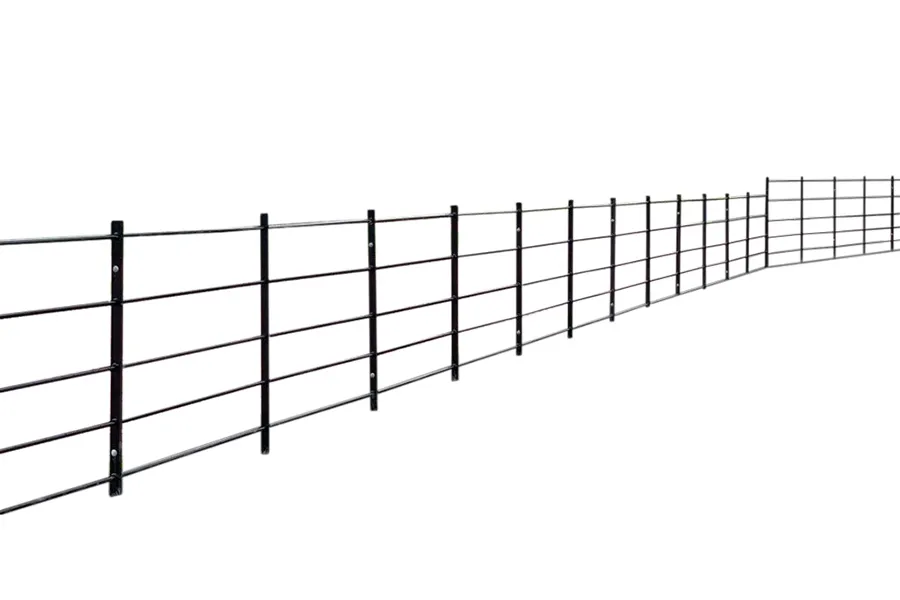

HERMEQ stock a wide range of Stillages, Site Storage, Permanent Fencing & Road Barriers conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Internal:

Load Capacity: 2000 kg

Height: 1375 mm

Width: 1340 mm

Length: 1340 mm

Weight: 250 kg

External:

Load Capacity: 2000 kg

Height: 1375 mm

Width: 1450 mm

Length: 1450 mm

Weight: 250 kg