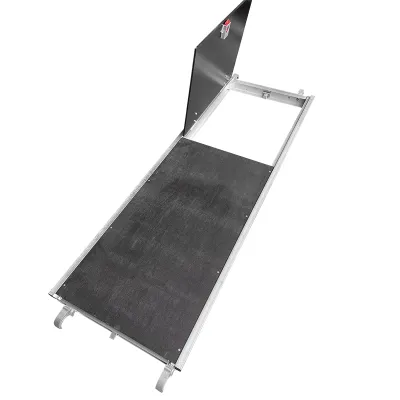

Scaffold Tower Span Frame

Product Highlights

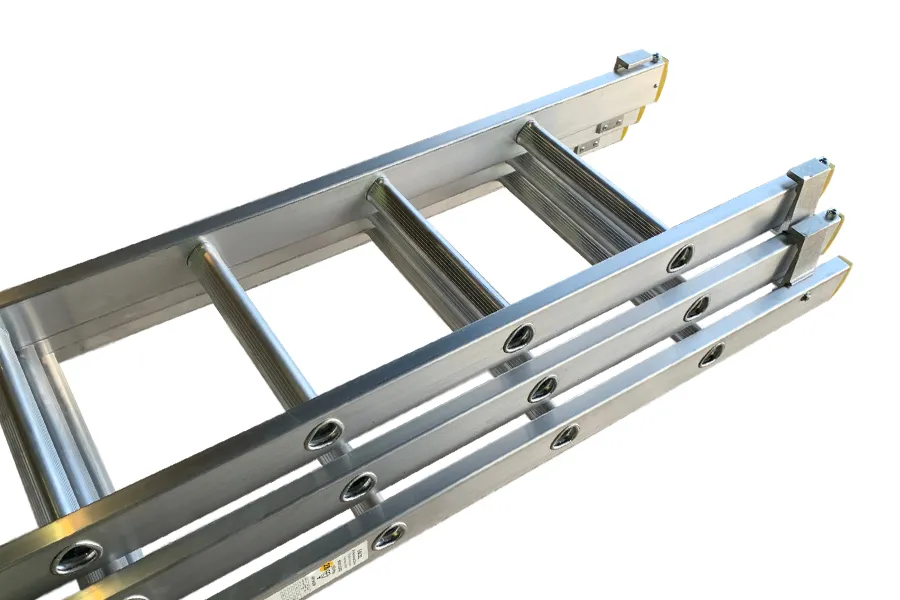

- Secure Platform Access - Non-slip ribbed rungs spaced at 200mm for climbing confidence.

- Durable Aluminium - Thick-wall tube construction designed for site longevity and safety.

- Flexible Sizing - Available in single/double width with 2–4 rung options for tailored use.

SKU SE500489

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

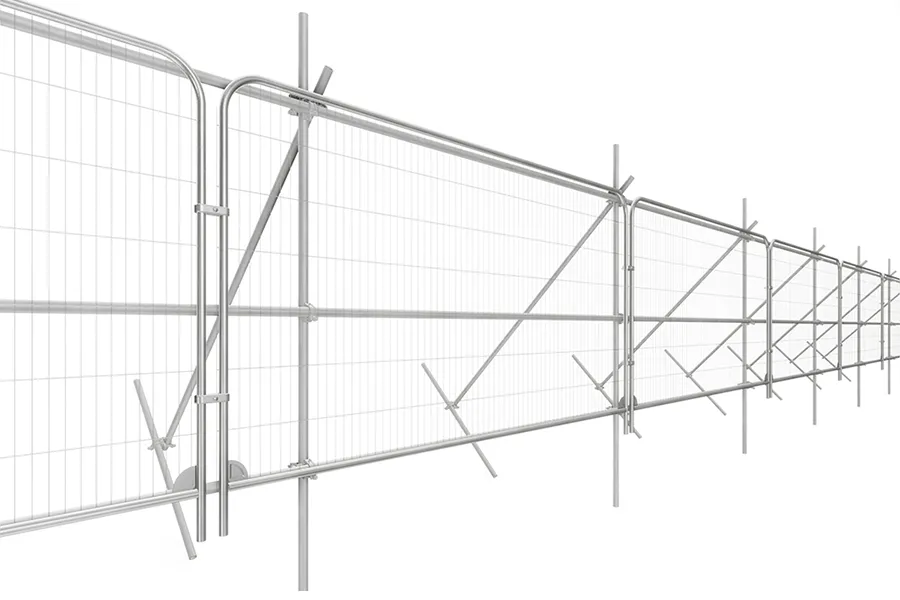

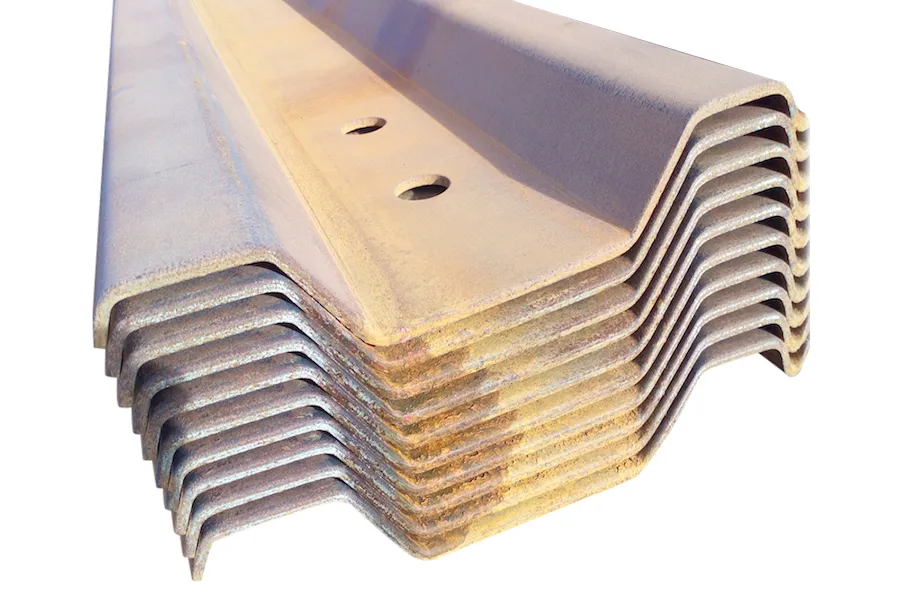

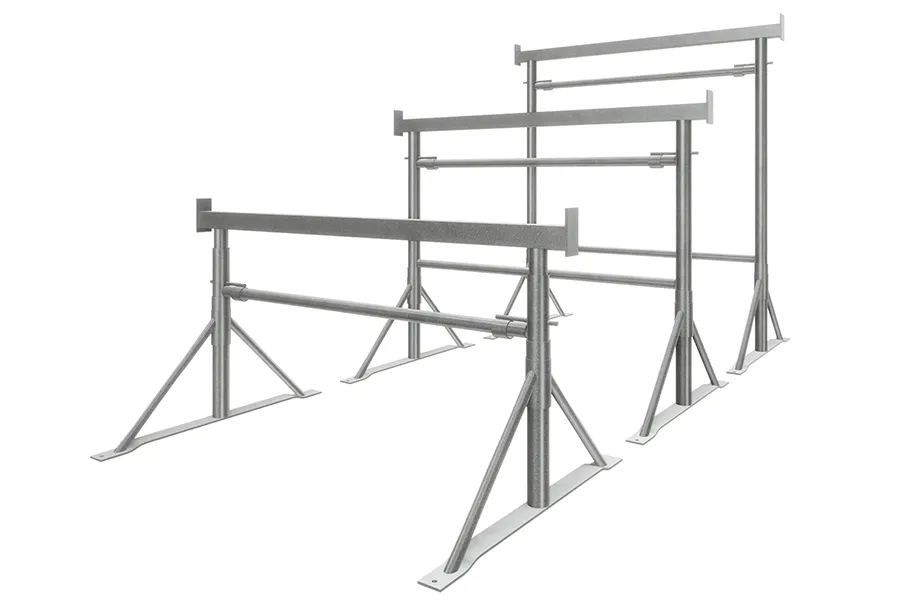

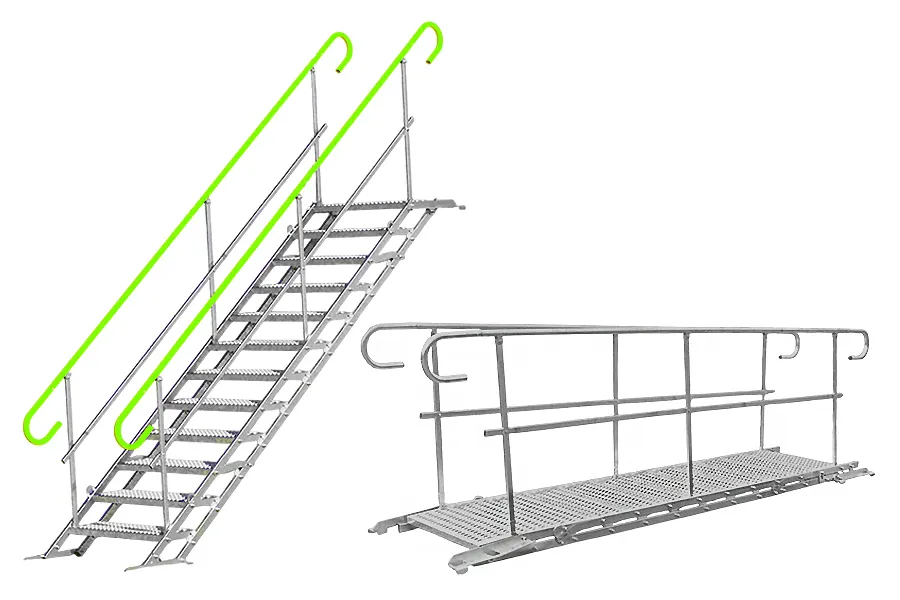

Span frames are a vital component of scaffold tower systems, providing the core structure needed to safely access multiple working heights. These units create the side frames between which platforms and braces are fixed, forming a solid working foundation. Constructed from thick-wall aluminium, these frames are engineered for daily site use and repetitive loading.

Each span frame is fitted with ribbed rungs at 200mm intervals, reducing slip risks and improving grip—especially useful when wearing boots or gloves. Available in both single (0.85m) and double (1.45m) width formats, they offer excellent flexibility depending on access needs and tower configuration.

- Reinforced aluminium structure - Engineered for long-term use on active sites.

- Modular design - Combine with other scaffold tower parts for height adjustment.

- Non-slip rungs - Ribbed for secure vertical climbing.

- Multiple sizes - Choose from 2, 3 or 4-rung options to match height needs.

- Optimised for safety - Contributes to full compliance on steel scaffold tower systems.

Perfectly suited for high-use sites, these span frames work across a wide range of scaffolding tower builds—from rapid access towers to long-term façade setups. Their ergonomic rung spacing and width flexibility support safe ascent and efficient platform positioning.

Built to strict industry standards, these span frames give contractors peace of mind on site. Whether you’re climbing, bracing or adjusting, the structural reliability of these frames supports faster and safer working practices across all scaffold tower types.

HERMEQ stock a wide-range of Ladders & Stairways, Scaffolding, Building & Working At Height equipment conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Why they matter:

– Provide safe support for scaffold tower platforms

– Form the main load-bearing wall frame in a modular scaffold tower

– Withstand daily wear and environmental exposure

Available as 2, 3 or 4-rung units, they allow flexible scaffold height setup. 0.85m (single width) units are ideal for compact zones and one-user towers, while 1.45m (double width) frames are best for multi-user access or heavier setups.

Every detail—from the rung pitch to the wall thickness—has been engineered for use across indoor and outdoor UK sites. Their non-slip rungs give secure access during poor weather or when transferring equipment between levels.

Contractors benefit from consistent frame sizing that speeds up build and dismantle cycles. Whether for rapid repairs or week-long builds, scaffold tower span frames remain a consistent component trusted across steel scaffold tower systems.

They are frequently used in commercial maintenance projects, building shell access, and internal warehouse work. Their lightweight yet robust design offers ease of transport, while still delivering the structural integrity that keeps operatives secure at height.

What sizes are available for these scaffold tower span frames?

They’re available in 2, 3 or 4-rung models and widths of 0.85m or 1.45m.

Can these be used with steel scaffold tower systems?

Yes, these span frames are fully compatible with steel scaffold tower configurations.

Are the rungs non-slip?

Yes. Each rung features a ribbed profile for added grip and safety when climbing.

Are they suitable for outdoor use?

Yes. Made from aluminium, they’re weather-resistant and built for site durability.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH