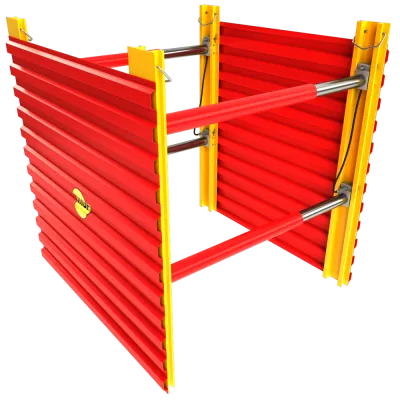

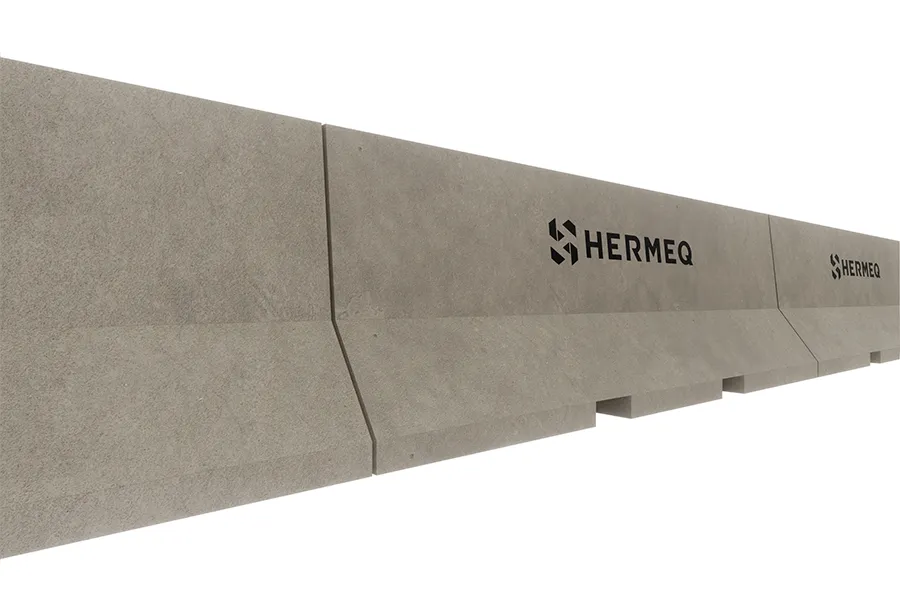

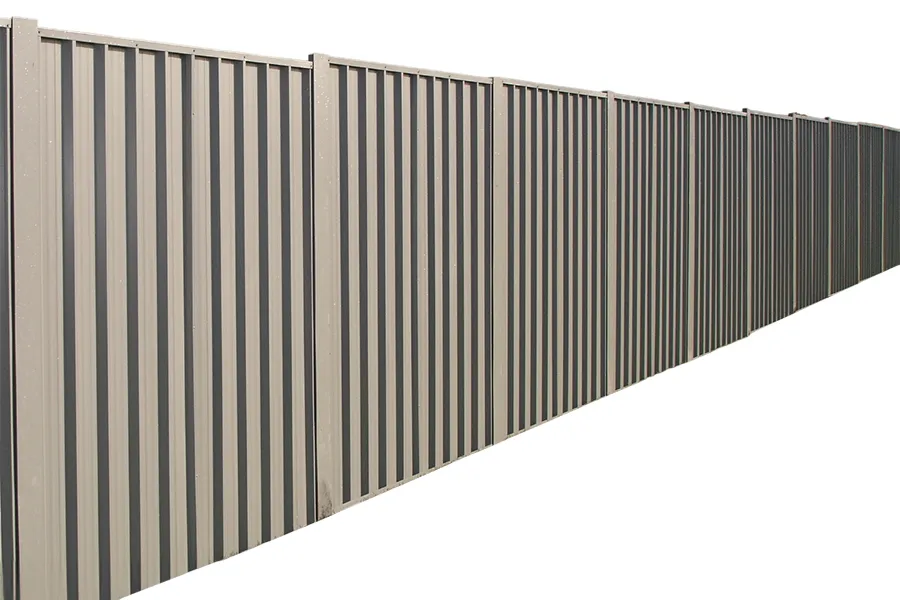

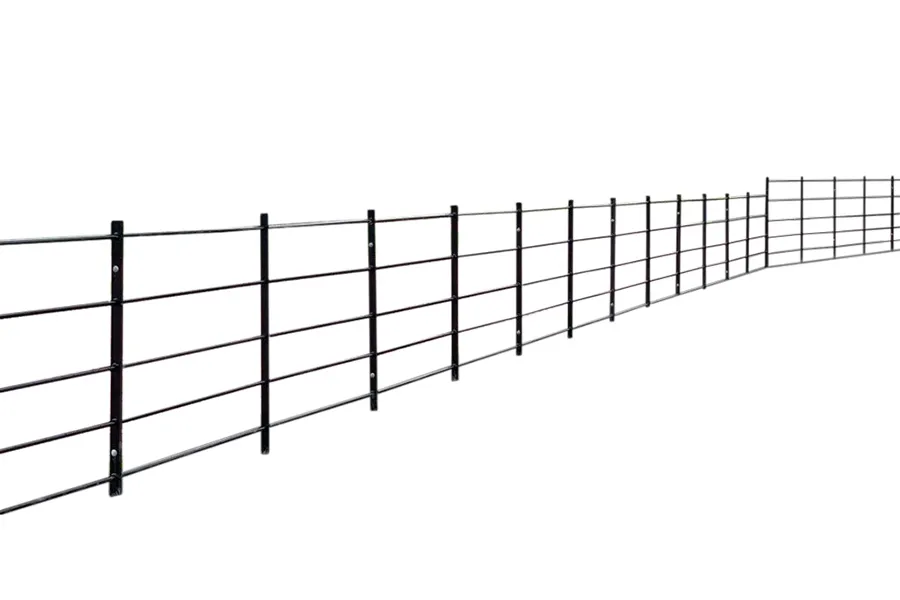

GRP Palisade

Product Highlights

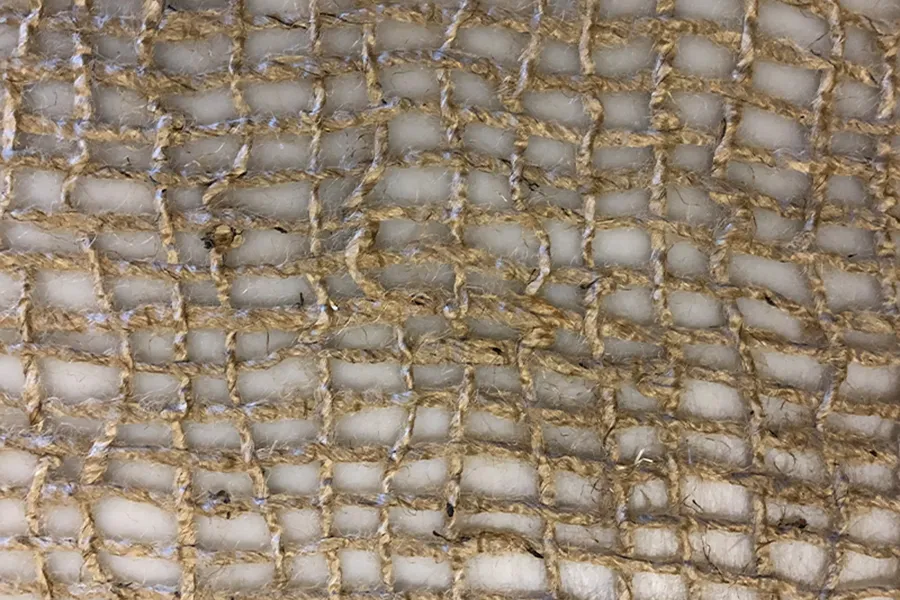

- Non-conductive and non-corrosive - Safe and reliable in power and chemical environments.

- Lightweight pre-assembled panels - Under 40kg, easy to handle, fast to install.

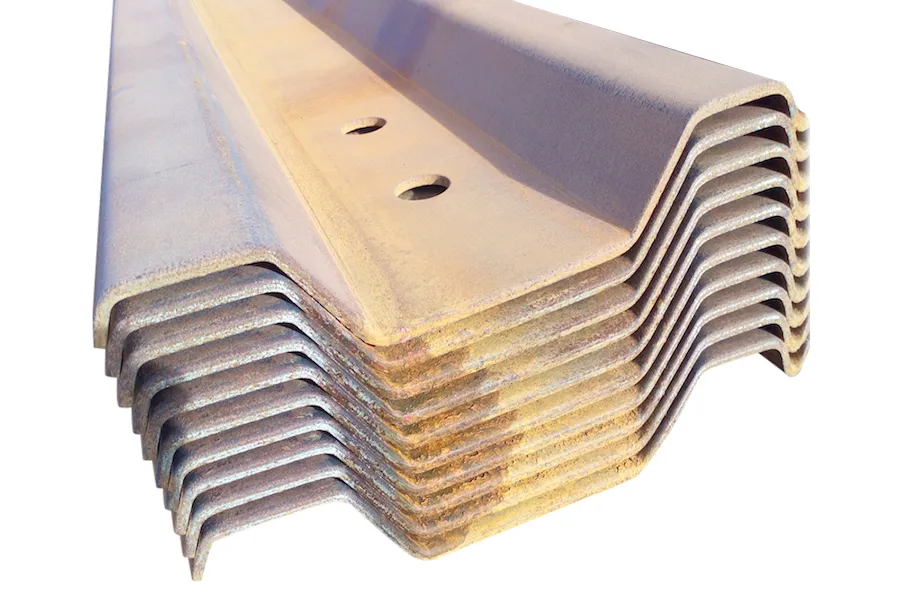

- Increased impact resistance - GRP pales absorb impact better than traditional steel fencing.

SKU GR7777

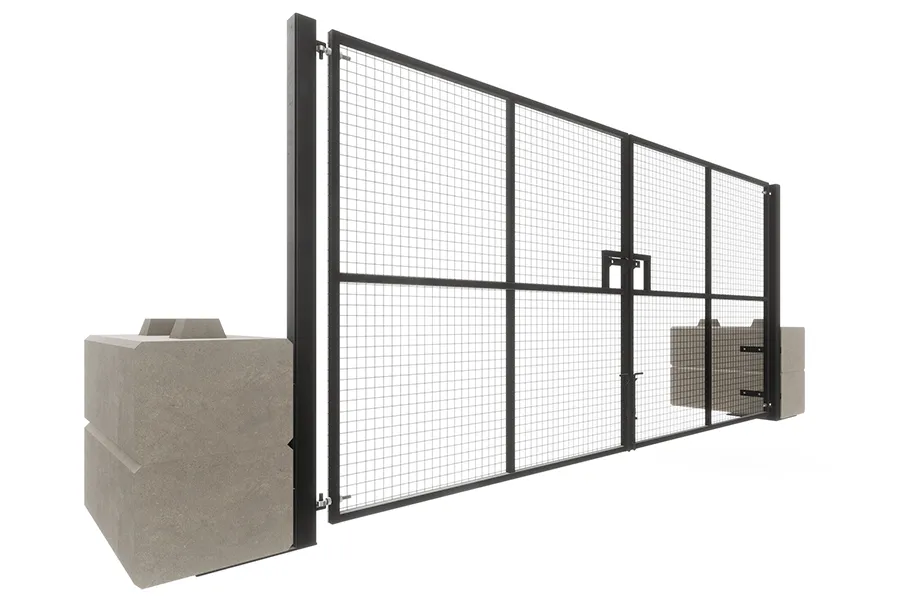

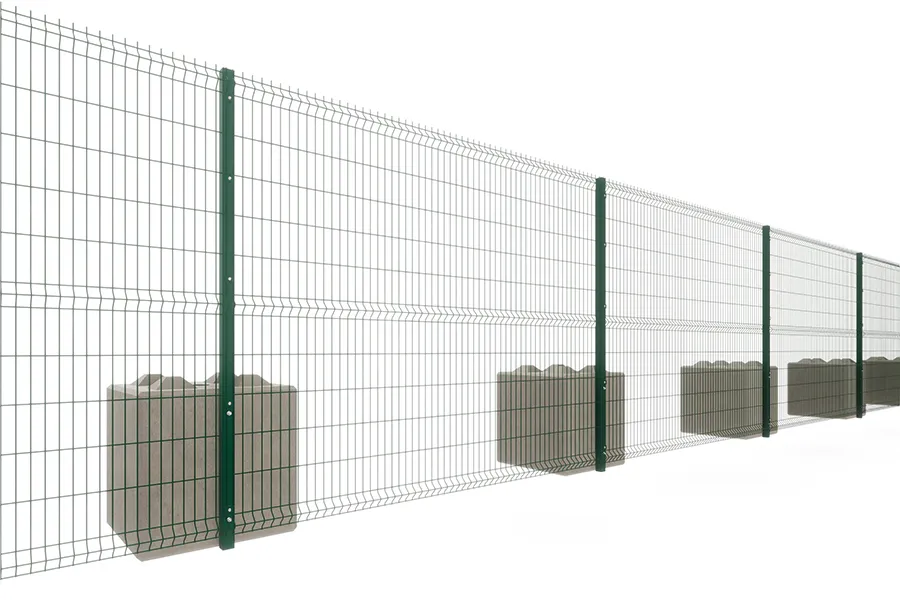

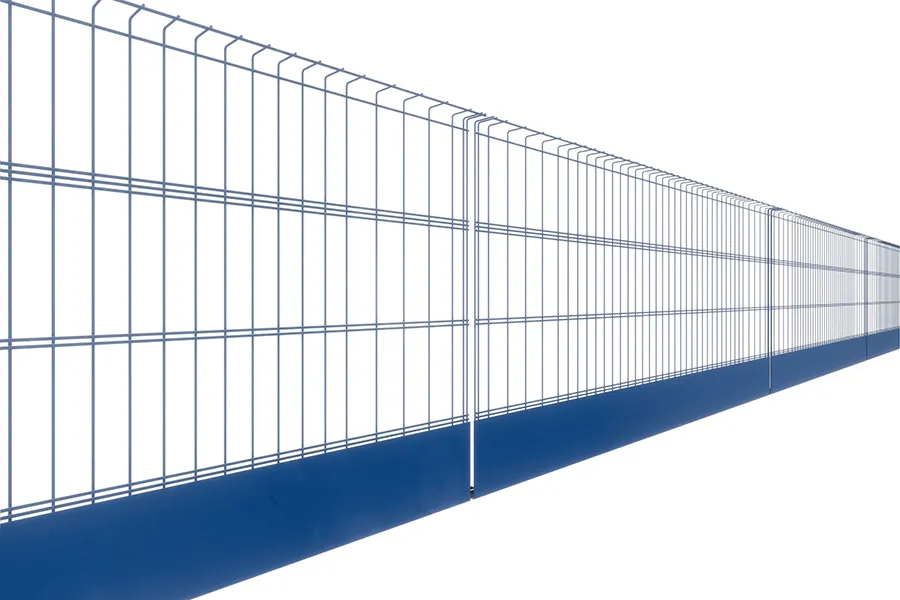

GRP palisade fencing from HERMEQ delivers a unique alternative to traditional steel palisade fencing, offering unparalleled corrosion and conductivity resistance. Ideal for energy, chemical and water industries, it provides critical safety benefits in high-risk environments.

Constructed from glass-reinforced plastic, these factory-assembled panels weigh under 40kg, allowing easy manual handling and rapid installation—without mechanical lifting equipment. This lightweight design is especially useful in restricted spaces like railways or substations where machinery access is limited.

- Non-conductive and corrosion-free - Essential for electrical and chemical risk zones.

- Factory-assembled for speed - Panels install faster than kit-built metal fencing.

- Strong and secure panel design - Pales pass through rails for improved security.

- Durable composite material - Resists impact and absorbs shocks without denting.

- Machinery-free installation - Panels are light enough for manual setup.

For sectors where traditional steel palisade fencing presents safety challenges, GRP palisade fencing is the ideal solution. Made from glass-reinforced plastic, the system is inherently non-conductive, significantly reducing the risk of electrical hazards at substations, power stations, and rail corridors.

Its resistance to corrosion ensures long-term structural integrity in environments such as waste treatment plants, chemical facilities, and coastal or wet zones. Unlike metal fencing, GRP maintains its performance without rusting or degrading—minimising lifetime maintenance and replacement costs. This makes it particularly suitable for water authorities and industrial sectors seeking a low-maintenance fencing solution.

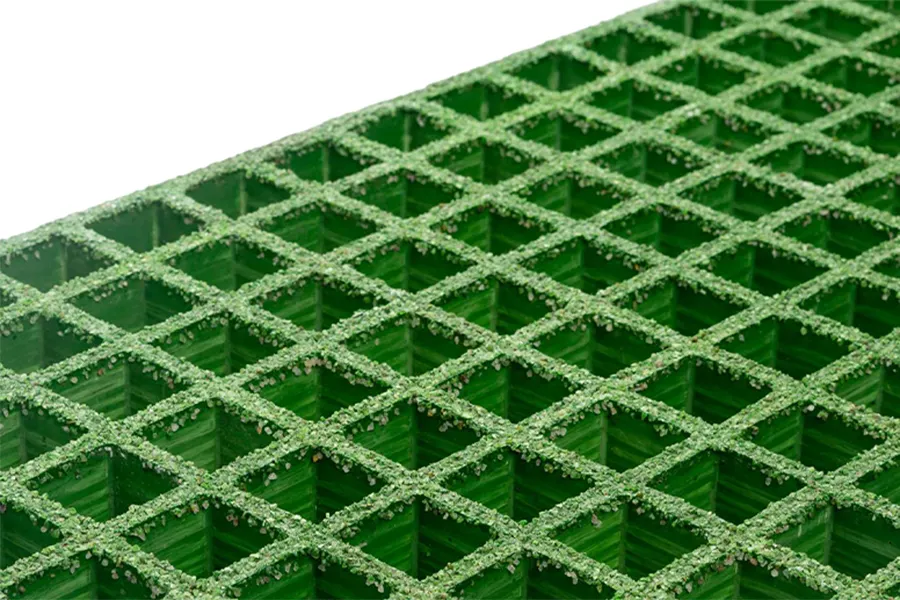

The GRP pales are engineered to pass through the top and bottom rails, offering superior security versus standard steel palisade fencing where pales are typically fixed externally. This embedded pale system prevents tampering and enhances structural rigidity. Despite its composite build, GRP’s dense fibre-reinforced structure is exceptionally impact-resistant, outperforming metal fencing in resisting dents and deformation from collisions.

In rapid-deployment scenarios such as emergency works or railway maintenance, the modular, lightweight nature of GRP fencing means panels can be quickly installed by hand. This removes the need for cranes or plant hire and allows contractors to complete installations in compressed timeframes.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Where It’s Used:

- Substations and power generation plants

- Railway infrastructure and trackside zones

- Water treatment facilities and pumping stations

- Petrochemical sites and hazardous storage areas

- Coastal or flood-prone industrial environments

GRP palisade fencing is revolutionising how safety fencing is deployed in UK infrastructure. Lightweight and modular, each panel is engineered to be handled and installed by two operatives without machinery. This is crucial in restricted-access areas or projects with limited installation time, such as overnight rail blockades or power outages requiring rapid fence replacement.

Compared to traditional steel palisade fencing, GRP delivers enhanced safety in live or corrosive environments. Its non-conductive properties eliminate the risk of arcing or shorts near cabling, while the composite build resists decay in chemically aggressive settings. This makes it a go-to option for safety-critical applications where downtime or maintenance is not acceptable.

The unique construction of the GRP system, with integrally locked pales passing through rails, adds further value. The panels resist dismantling attempts, improving perimeter integrity for sites prone to vandalism or unauthorised access. Despite being composite, GRP can withstand high impacts without structural damage, bending, or splintering—unlike dent-prone steel fencing.

What are the benefits of GRP palisade fencing over metal fencing?

It is non-conductive, corrosion-proof, lightweight, and faster to install. Ideal for environments unsuitable for steel palisade fencing.

Can GRP panels be used in chemical and wet areas?

Yes, GRP is corrosion-resistant and perfect for waste water, chemical zones, or coastal installations where metal would degrade.

Is the fencing secure enough for industrial use?

Yes. GRP pales pass through the rails, offering better tamper resistance and structural stability than some metal fencing options.

Do I need machinery to install this fencing?

No. Panels are under 40kg and pre-assembled. They can be installed by hand without plant or lifting equipment.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH