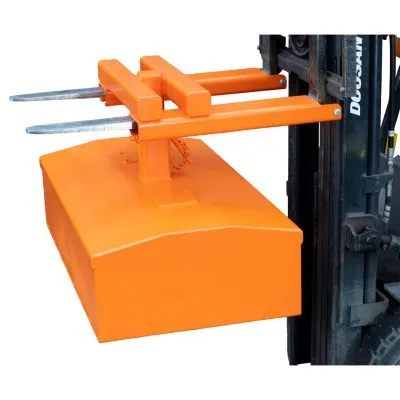

Fork Mounted Articulated Extendable Jib

SKU IA5623

The Fork Mounted Extendable Jib is a fully adjustable jib with angular lift capabilities that allow for the transportation of awkward and tall loads with ease.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

The Fork Mounted Extendable Jib is a top-of-the-range jib that is much more versatile than the average jib, allowing it to perform angular lifts and lift abnormal loads.

Alongside these impressive versatility improving features, the Fork Mounted Extendable Jib also benefits from a multi-hook positioning feature that allows for awkward or abnormal loads to be securely loaded regardless of their shape or jib height requirements required.

The multi-hook is capable of positioning from 950 mm to 3850 mm load centres, with the angled lift increasing in 15° increments from 0° to 45°. These capabilities make the Fork Mounted Extendable Jib one of the leading Fork-Mounted Jibs available for purchase as many other Fork Mounted Jibs simply cannot provide anywhere near the number of options that this jib provides.

When using the Fork-Mounted Extendable Jib, the health and safety of the users and individuals in the surrounding work environment should always be the highest priority. Before use, always conduct an in-depth risk analysis ensuring that the equipment can be used safely and efficiently and that the equipment being used is capable of bearing the load being lifted.

The maximum load capacity of the Extendable- Jib varies depending on the positioning of the multi-hook and the angle of the jib. These various capacities can be found further down this product description and have been provided by the manufacturer, guaranteeing the reliability of the equipment and giving a true representation of the jib's strength.

To begin using the Adjustable Jib, the forks of the forklift must be set to the correct distance required to fit into the fork pockets located on the base of the jib.

To allow the forks to enter the forklift pockets, the user must first remove the heel pins from the jib attachment. Once removed, the forks should be driven into the forklift pockets.

The previously removed zinc-plated heel pins are then used to safely secure the jib to the forklift truck by reinserting the heel pins into the holes behind the heel of the fork.

Each swivel hook and shackle to the lifting point required, making sure that they are correctly attached and can adequately support the load intended for lifting.

The next stage of the setup process is to extend or retract the extending boom by removing the beam locating pin and pulling or pushing on the handle located at the end of the boom. This should be done until the hole in the extending boom aligns with the hole in the beam. Once correctly positioned the beam locating pin needs to be returned to the aligned holes.

The Extendable-Jib is now ready for use. In order to obtain to desired lift angle, lift the end of the extension beam until the hole and fixed frame align replacing the pins to secure the angle in place.

To ensure the safe and efficient use of the Fork Mounted Extendable Jib is maintained throughout the continuous use of jib, regular maintenance checks should be conducted.

Weekly checks should focus on general wear and tear, the condition of the fork pockets, heel pin attachments, swivel hook, safety latches, shackles, the extending boom, and all weld points.

If any damages or safety concerns are found they should be reported and repaired immediately. This is an important requirement that should be adhered to at all costs in order to avoid any health and safety issues.

The product life and safety levels of the Fork Mounted Extendable Jib can be extended by treating any surface rusting with proprietary inhibitors, paint, and primers regularly.

The Extendable Jib is certified for six months from the manufacture date, the customer is then responsible for having the jib regularly tested by the appropriate testing facility.

To further protect the user and minimise the possibility of accident or injury, health and safety evaluations should be conducted to ensure the equipment is suitable for use in the intended environment and that the equipment is capable of lifting the weight of the object intended for lifting.

All heel and shackle pins should be checked that they are correctly inserted and tightened appropriately when in use. When inserting the forks of the machinery into the Fork-Mounted Extendable Jib, the heel pins should be removed.

Throughout use, the maximum load capacity should not be exceeded at any point and should be checked consistently to ensure the lifting point in use can accommodate the load lifted.

The Fork Mounted Extendable Jib should not be shock-loaded in any circumstances as the integrity of the jib has not been designed to withstand shock loading.

While using the Fork Mounted Extendable-Jib, the forklift mast must always remain vertical.

Specifications:

Fork Mounted Extendable Jib Option 1

Max load capacity: 1000 kg at 950mm load centre

Weight: 295 kg

C of G: 840 mm -1115 mm

Fork Mounted Extendable Jib Option 2

Max load capacity: 2000 kg at 950mm load centre

Weight: 300 kg

C of G: 840 mm -1115 mm

Fork Mounted Extendable Jib Option 3

Max load capacity: 3000 kg at 950 mm load centre

Weight: 310 kg

C of G: 840 mm -1115 mm

Fork Mounted Extendable Jib Option 4

Max load capacity: 4000 kg at 950mm load centre

Weight: 315 kg

C of G: 840 mm -1115 mm

Fork Mounted Extendable Jib Option 5

Max load capacity: 5000 kg at 950mm load centre

Weight: 305 kg

C of G: 840 mm -1115 mm

Delivery:

Delivery times can vary and are stock dependant. Average delivery times are between 24 hours and 5 working days.

If you have any questions please call us on 0121 725 2338.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH