Crane Pallet Forks - Self-Balancing

SKU IA3012

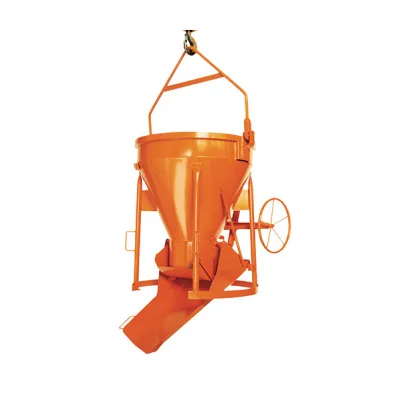

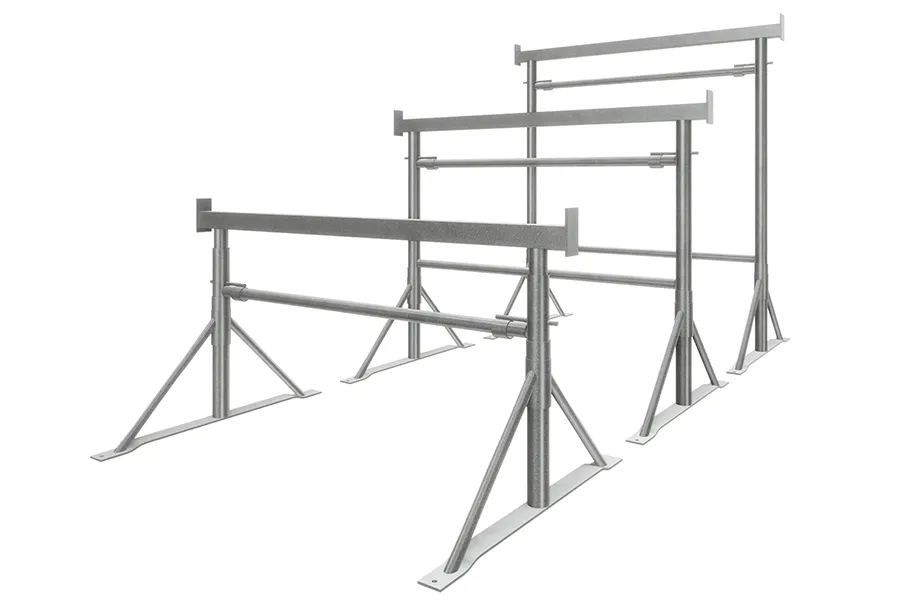

The Automatic Pallet Forks effectively convert an overhead crane into an effective pallet mover. There are many applications where fork trucks cannot be operated due to a lack of floor space for example high rise developments. Our crane forks are equipped with adjustable forks, height adjustment and an automatic balancing sprung head along with pre-fitted restraint net frame (net supplied separately).

| Fork Length (mm) | Fork Cross Section (mm) | Fork Opening Range (mm) | Overall Height (mm) | Weight (kg) | Load Capacity (kg) |

| 1000 | 100 x 35 | 300 - 1000 | 1800 - 2500 | 170 | 2000 |

| 1200 | 100 x 35 | 300 - 1000 | 1800 - 2500 | 190 | 2000 |

Standard Features

- Spring loaded self-balancing head.

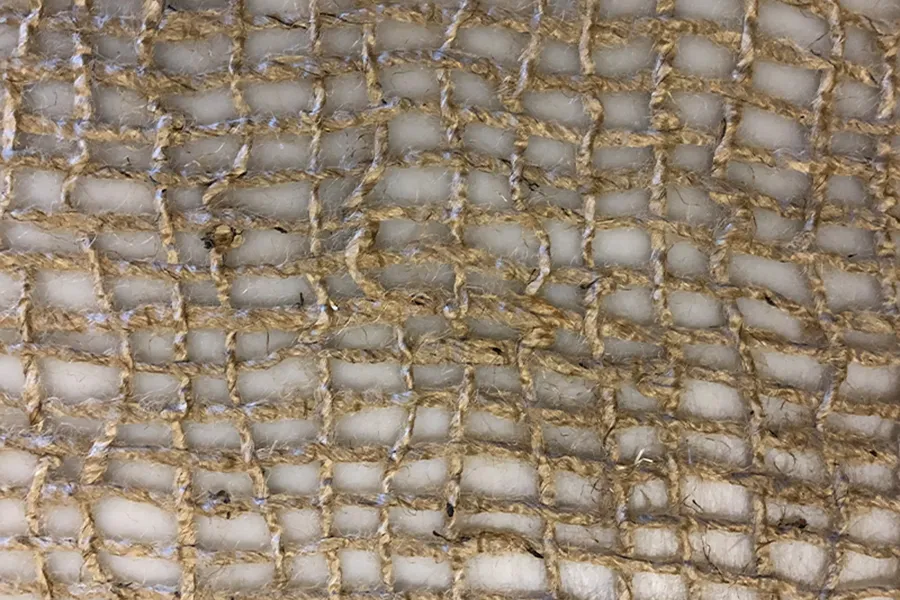

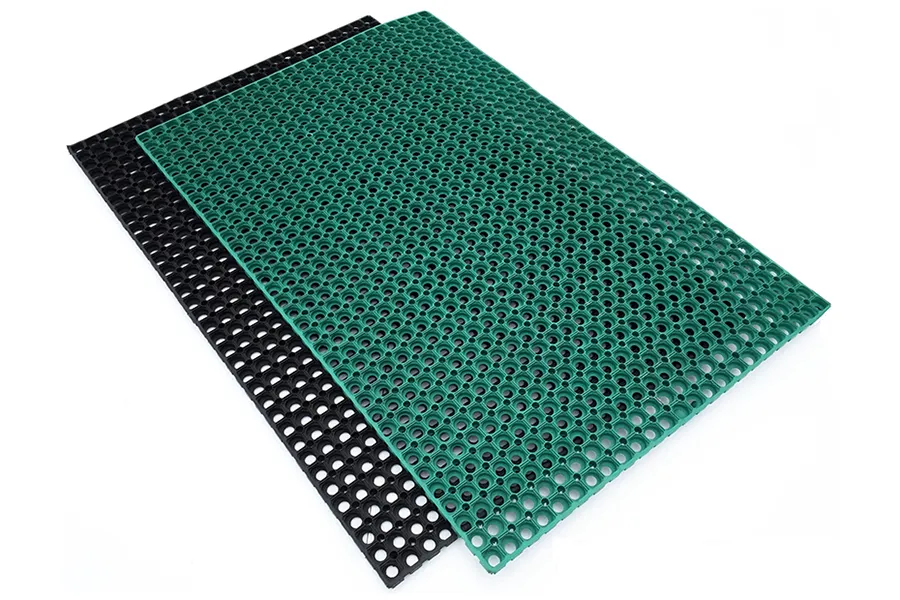

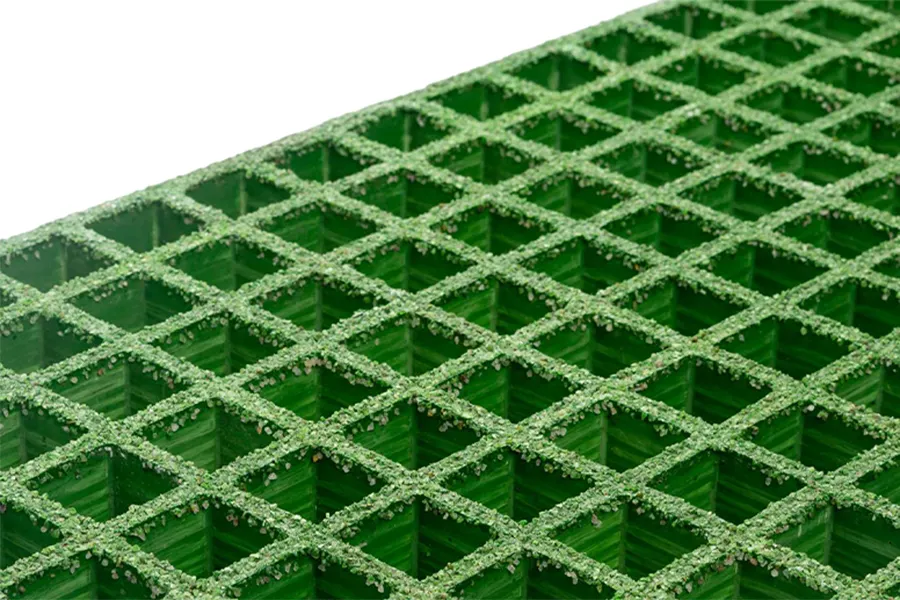

- Safety Net Frame

- Adjustable Height – Clear Height 1200-1900mm

- Adjustable Fork Widths

- Convenient Hand Holds

- Painted bright yellow for safety

Operation

- Operate overhead crane / HIAB into position directly over the crane forks.

- Place the crane/HIAB hook onto the lifting eye of the attachment.

- Slacken the thumbscrews to position the forks at the widest possible distance apart to suit the pallet.

- Retighten thumb screws onto rail ensuring that they are adequately tightened and secure.

- With the pallet forks slightly raised, manually re-position the Pallet Forks to enter the pallet with the handles provided on the rear of the frame.

- Operate overhead crane / HIAB to enter the forks fully into the pallet.

- Once fully inserted into the load, place the safety strap around the load & secure.

- Lift the pallet clear of the ground and slide restraint net underneath. Attach to the six net hoops on the frame. Always use a restraint net when lifting overhead.

- When positioned correctly & secured, the load is ready for movement.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH