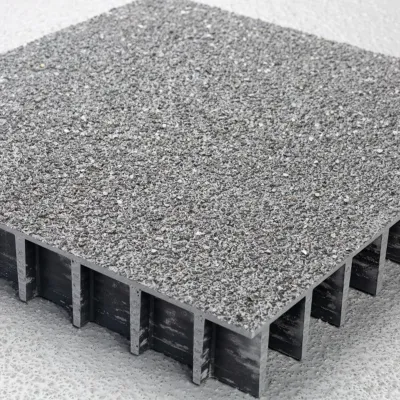

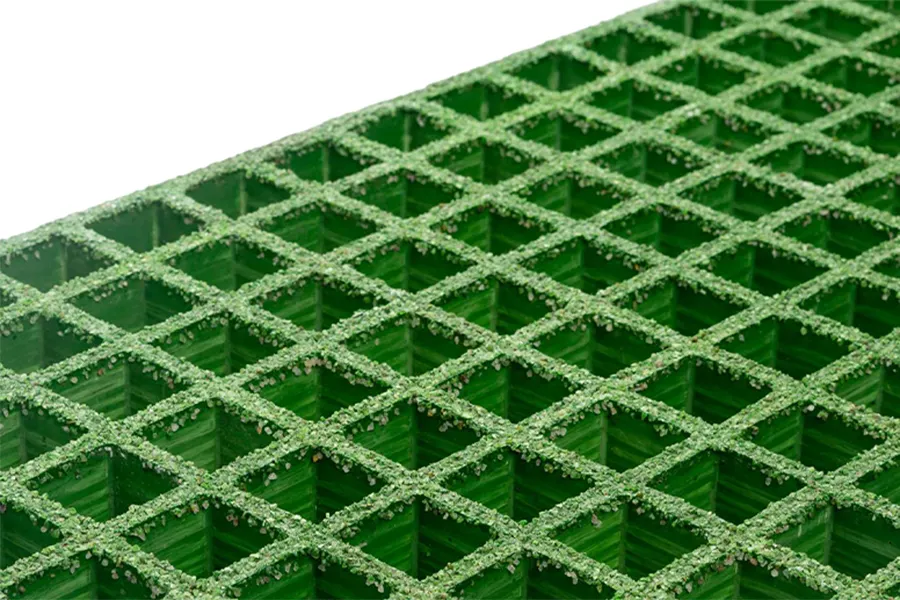

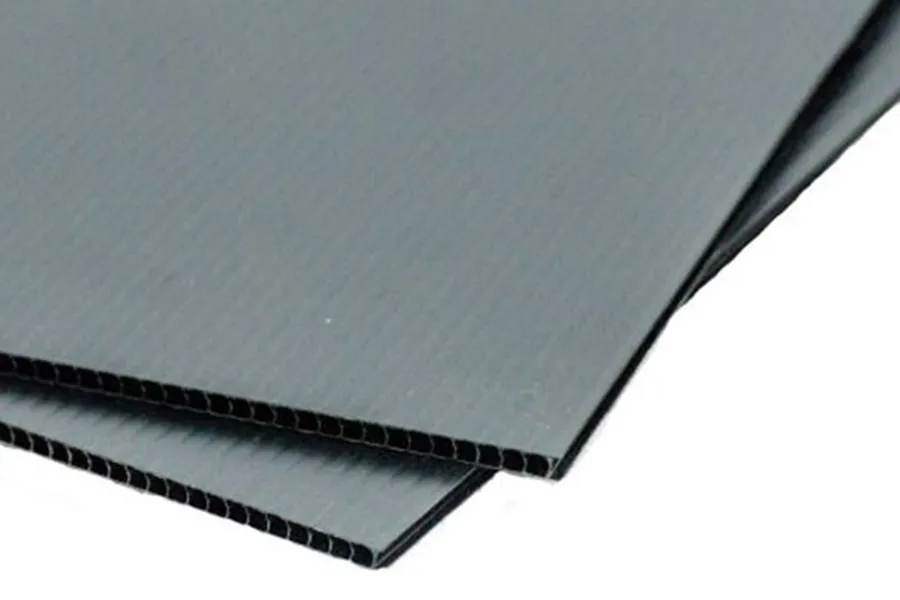

GRP Floor Grating Panels

SKU GR237810

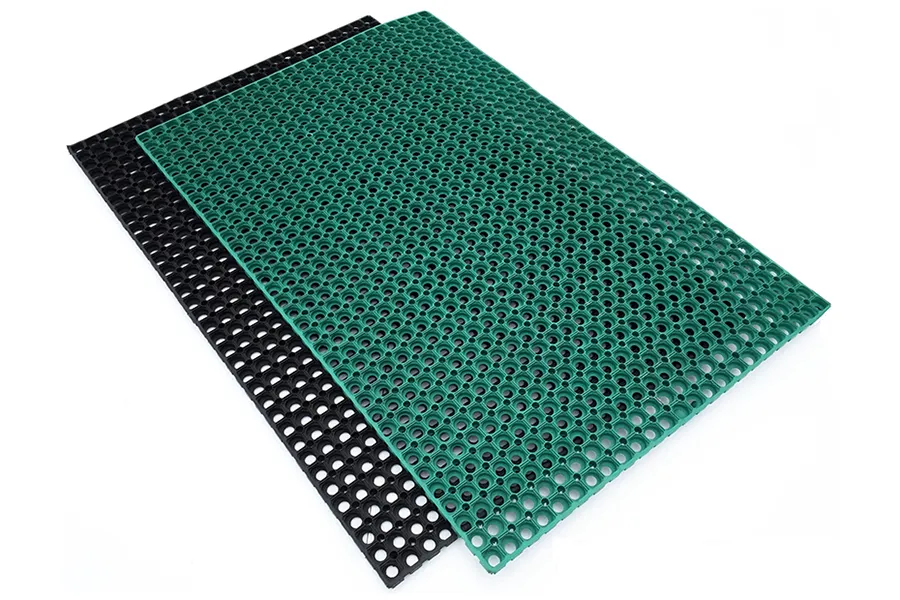

GRP (Glass Reinforced Plastic) Floor Grating Panels are used for walkways, platforms, risers, trenches and mezzanine decks.

GRP is used as it has a high strength-to-weight ratio whilst being a lightweight material – it is long-lasting, durable and tolerant of harsh environments due to its high corrosion resistance.

Available in a range of depths, colours and panel sizes.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

The mesh size of each of our panels enables effective and easy drainage and debris fall prevention when installed as flooring to ensure protection for workers and machinery.

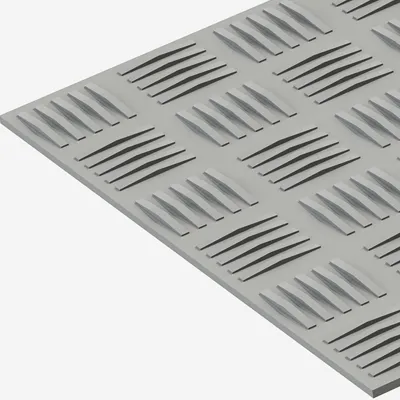

Used extensively in rail, power and marine industries, these panels can be used as a debris litter screen as well as machine guarding when applied vertically. GRP Floor Grating Panels are up to 50% lighter than steel grating panels and are finished with a hard-wearing, anti-slip gritted surface to ensure enhanced slip-resistance making it the ideal choice for marinas, jetties, pontoons and gangways.

GRP Floor Grating Panels are estimated to last between 50 and 100 years depending on the conditions due to their extremely long-lasting and durable nature – this is due to their ability to withstand harsh working environments where they may see extensive levels of use.

GRP is a waterproof material used extensively in the marine industry sector. It is able to withstand environments in which it is regularly exposed to water whilst maintaining great levels of slip resistance in the process.

GRP is also resistant to UV light and will not deteriorate as a result of UV light exposure making it an ideal product to choose where this is an important factor.

Benefits:

-

Corrosion Resistance: One of the primary advantages of GRP floor grating panels is their exceptional corrosion resistance. They are impervious to rust and corrosion, making them ideal for environments exposed to moisture, chemicals, or saltwater.

-

UV Resistance: GRP panels are resistant to UV degradation, ensuring they maintain their structural integrity and appearance even when exposed to sunlight for extended periods. This makes them suitable for outdoor applications.

-

Low Maintenance: GRP floor grating requires minimal maintenance compared to traditional materials like steel. They do not need painting or coating to protect against corrosion, reducing ongoing maintenance costs.

-

Lightweight: GRP panels are significantly lighter than steel grating panels, making them easier to handle and install. This characteristic also reduces transportation costs and simplifies installation procedures.

-

Easy Installation: Due to their lightweight nature and often modular design, GRP grating panels are easy to install. They can be quickly assembled and require fewer resources compared to heavier materials.

-

Excellent Slip Resistance: GRP floor grating panels can be manufactured with an anti-slip surface, enhancing safety in areas where slip resistance is crucial. This feature makes them suitable for industrial floors, marine decks, and other environments where wet conditions are common.

-

Low Life Cycle Costs: Because of their durability, corrosion resistance, and low maintenance requirements, GRP floor grating panels offer low life cycle costs. They have a long service life and retain their performance characteristics over time, minimising the need for replacements or repairs.

Applications for GRP Floor Grating Panels include industrial settings (such as chemical plants and manufacturing facilities), marine and offshore installations (like docks, platforms, and walkways), commercial buildings, and transportation infrastructure (such as railway stations and airports). The combination of these benefits makes GRP floor grating panels a versatile and cost-effective choice for various demanding environments.

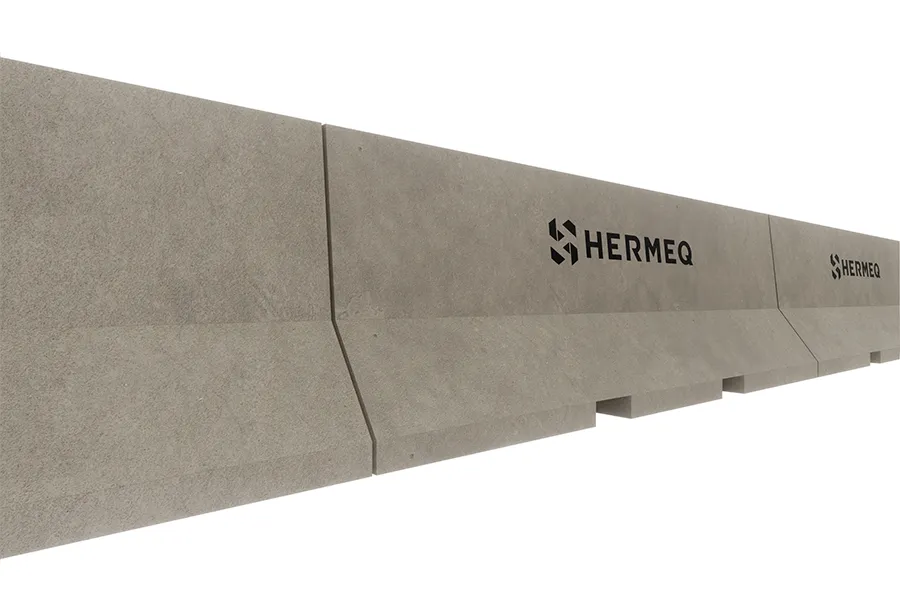

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH