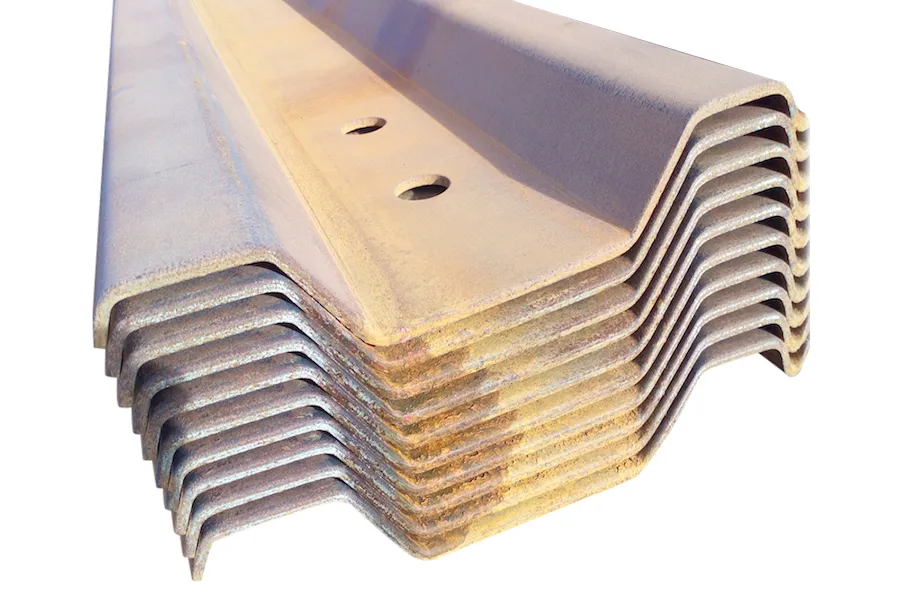

L8 Interlocking Sheet Piles

Product Highlights

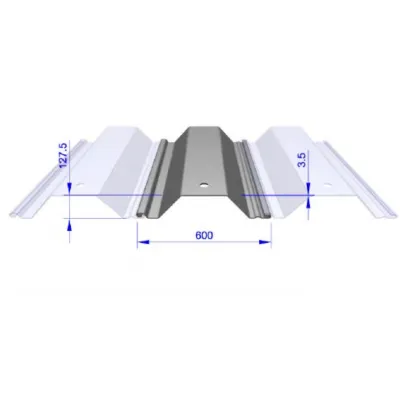

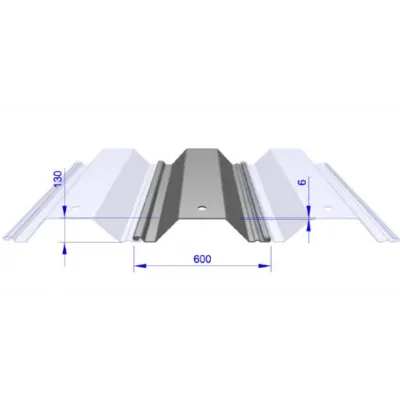

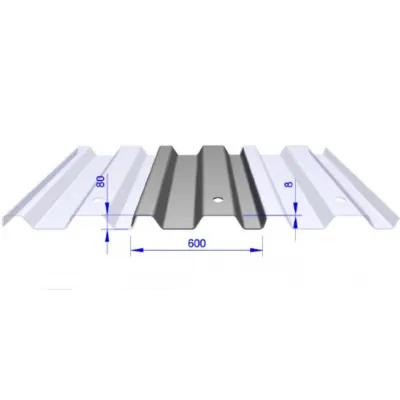

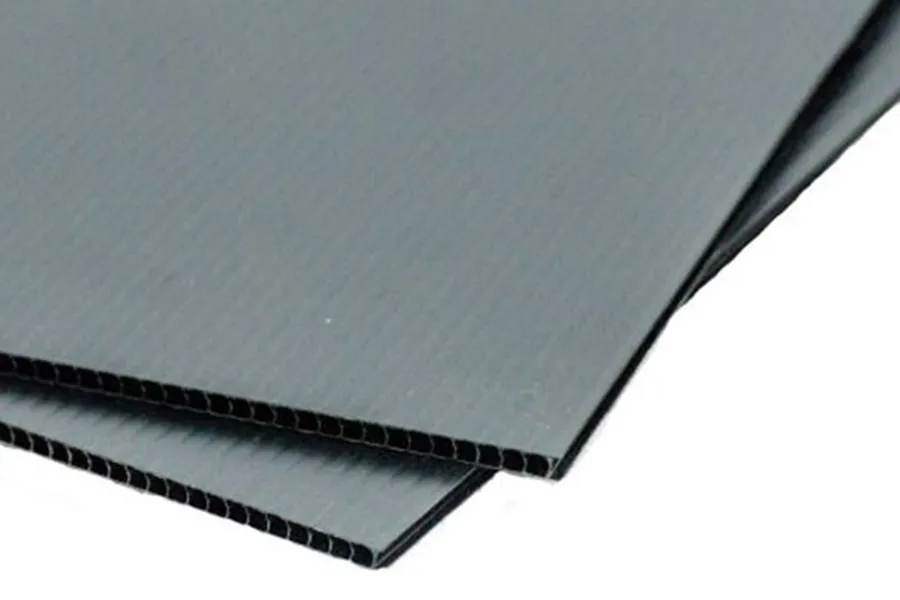

- 3.5mm thick steel - Cold-rolled trench sheets made from durable S235JR material.

- 1–6m sizes - Supplied in multiple lengths for excavation, canal and structural use.

- Rapid UK delivery - Quick nationwide delivery direct from HERMEQ's depot network.

SKU TR1500

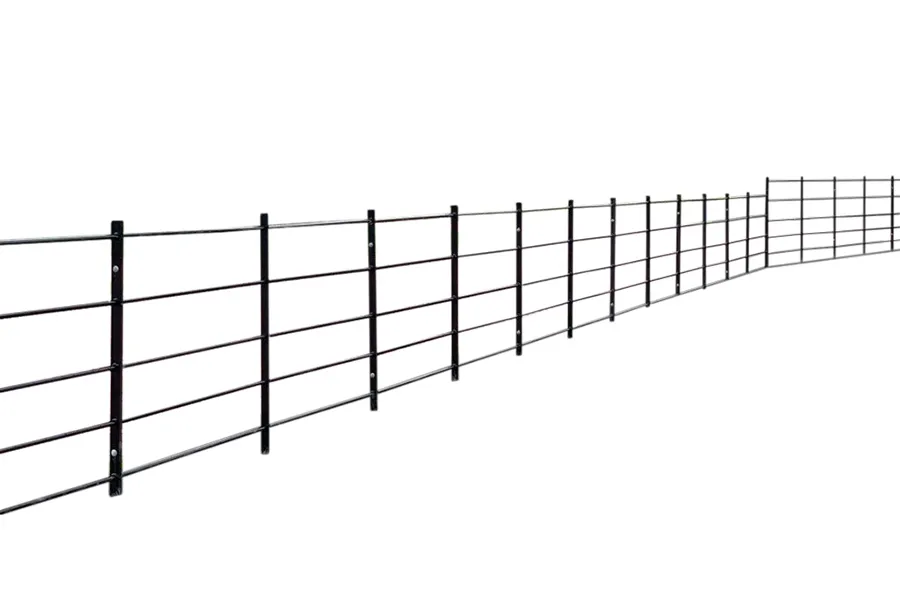

HERMEQ's L8 Sheets Piles are a 3.5mm thick interlocking steel sheet pile ideal for UK marine & groundworks. Manufactured in-house, these trench sheets provide superior structural integrity and ease of handling. Available in lengths from 1m to 6m, they deliver reliable performance in civil engineering, canal walling and excavation projects requiring long-term soil retention and corrosion resistance.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

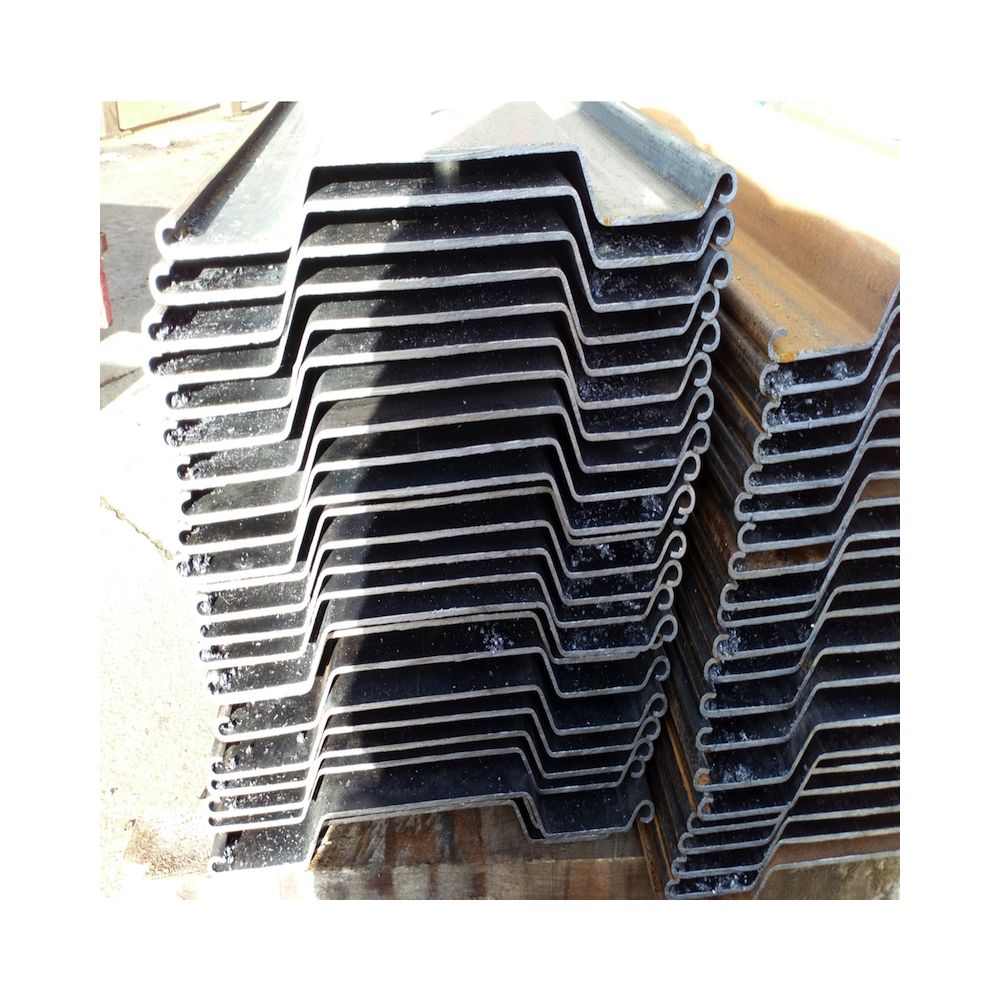

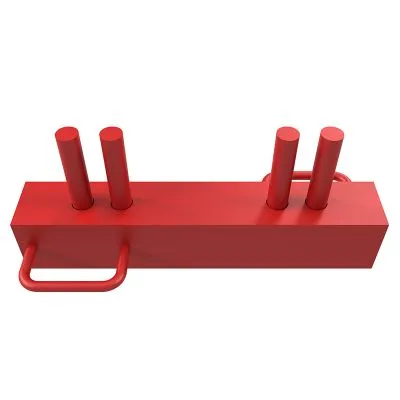

The in-house manufacturing process begins with coil slitting, followed by roll forming into L8 profiles with pre-cut lifting holes for safe handling. The finished steel sheet piles are banded, stacked, and dispatched to depots or job sites. Thanks to its full UK supply chain, HERMEQ ensures traceability, short lead times, and a consistent supply of trench sheets and sheet piles for sale.

- Wide range of lengths – Supplied in 1m to 6m formats to suit a variety of excavation or shore retention applications.

- High strength construction – Cold-rolled from 3.5mm S235JR steel for strong soil retention and edge interlocking.

- Fully interlocking edges – Provides better sealing and ground stabilisation than overlapping trench sheets.

- UK manufacture – Quick turnaround and full material traceability with national next-day delivery service.

- Versatile applications – Suitable for temporary or permanent retaining walls, marine use and flood defences.

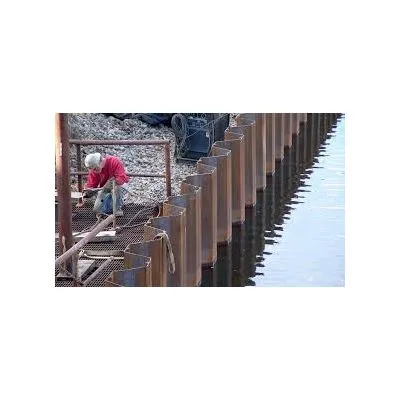

HERMEQ L8 trench sheets are ideal for canal banks, marinas, deep excavations, and infrastructure requiring robust lateral support. The trench sheet profile improves on-site efficiency and reduces the labour required compared to traditional shoring systems. Options for vibratory or hydraulic installation provide flexibility depending on soil composition and vibration sensitivity.

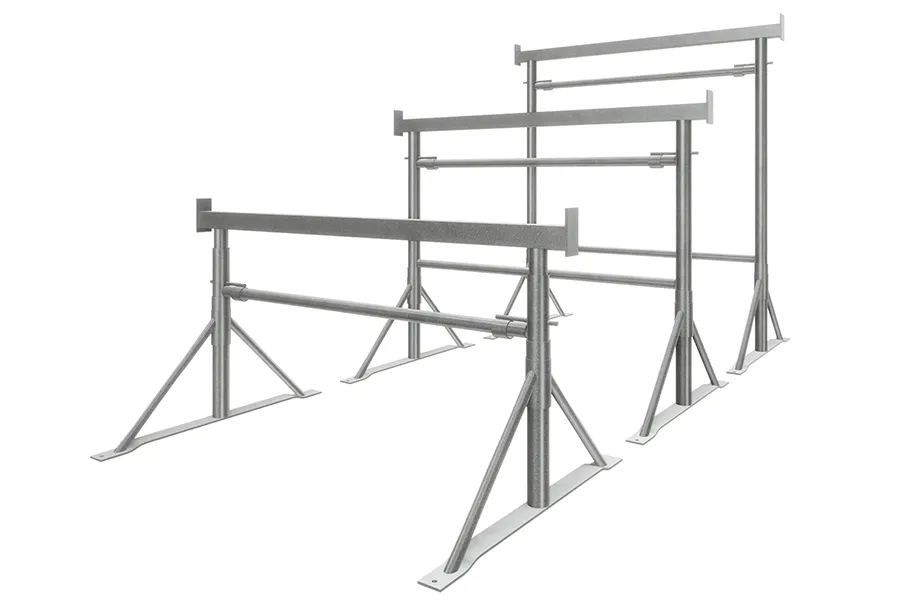

As a major supplier to the UK canal and river trust, HERMEQ’s sheet piles help manage water ingress in flood-prone or marshy areas. Guide walings and piling frames are also available to simplify alignment and handling. HERMEQ manufactures up to 60 tonnes of trench sheeting daily, ensuring capacity for both one-off and bulk orders.

HERMEQ stock a wide-range of Trench Sheets, Groundworks, Trench Covers & Road Plates conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

• Shoring excavations and trenches

• Building temporary retaining walls

• Canal reinforcement and water bank edging

• Ground retention in civil infrastructure

Applications:

These steel sheet piles are widely used across the UK for ground stabilisation in both temporary and permanent structures. L8 trench sheets provide secure interlock and corrosion resistance, making them suitable for projects involving water ingress, flood prevention, or compact ground handling conditions.

With cold-rolled precision and galvanised protection on request, they’re a trusted solution for canal and river works, excavation lining, and ground retention systems. They are favoured by contractors due to HERMEQ’s fast availability, consistency, and ability to manufacture at scale. Combined with guide walings and piling frames available from HERMEQ, trench sheeting installation becomes faster, safer, and more accurate on-site.

| Effective Width | 434mm |

| Depth | 37.5mm |

| Thickness | 3.5mm |

| Cross sectional area per sheet | 18.5cm2 |

| Steel grade | S235JR |

What is trench sheeting used for?

Trench sheeting retains soil in excavations and prevents collapse in civil or marine works.

What lengths are L8 trench sheets available in?

Lengths range from 1.0m to 6.0m, with additional custom sizes available upon request.

Are L8 trench sheets suitable for water environments?

Yes. Their interlocking steel profile makes them ideal for canal walls, marinas, and flood defences.

How are sheet piles installed?

They can be vibrated, hammered, or hydraulically pushed into position depending on ground conditions.

HERMEQ UK

HERMEQ UK HERMEQ Ireland

HERMEQ Ireland HERMEQ Netherlands

HERMEQ Netherlands HERMEQ France

HERMEQ France HERMEQ DACH

HERMEQ DACH